Single Shaft Double Shafts Waste Plastic Metal Wood Shredder Crushers for Lumps Bottles ...

Suzhou Acmtech Machinery Co., Ltd.- Type:Hard Plastic Crusher

- Raw Material:Mixing

- Structure:Top Feed

- Knife Classification:Claw Knife Crusher

- Knife Roll:Solid Knife Roller

- Automation:Automatic

Base Info

- Model NO.:acm

- Computerized:Computerized

- Certification:CE, ISO9001:2008, UL

- Motor:Siemens,Honeywell,Wn

- Blade Material:SKD-11,D2,9crsi

- Warrenty Time:13 Monthes

- Application:All Plastics

- Inverter:ABB

- Electrical Parts:Schneider,Ls,Siemens,Omron,ABB

- Blade:Fixed and Rotary Blade

- Capacity:50-2000kg,Hr

- Operation Control:PLC

- Machine Material:Steel and Ss

- Design Origin:Europe

- Export:All Over The World

- Machine Color:Customized

- OEM:Available

- Agent:Needed

- Transport Package:Strench Film and Wood Pallet

- Specification:ACM-C-500

- Trademark:ACM

- Origin:China

- HS Code:8477800000

- Production Capacity:200 Sets

Description

Overview

Product Description

After Service

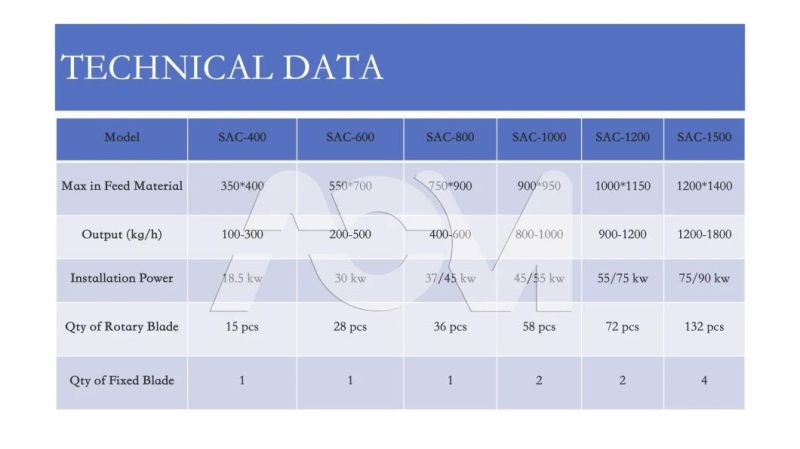

Product Parameters

Our Advantages

Client's Factory

After Service

| Technical documentation |

| All symbols on the equipment will be in English. We will be responsible for providing the Buyer with a general layout plan, electrical plan, installation orientation and manuals, in English. |

| Arrangements for inspection, installation and testing of the equipment |

| a. After all of the equipment is delivered to the customer's factory, the Buyer shall be responsible for all preparation work, e.g. electricity supply, water supply, cranes and labor, etc. b. We will prepare visa applications for their engineers, who will assist in the equipment installation and testing at the Buyer's factory. c. The Buyer will buy a round-trip air ticket for the engineer(s) after the visa application is approved. The Buyer is responsible for all expenses generated, e.g. visa application fees, meals, accommodation and an allowance of $80.00 per day for each engineer. d. The engineer(s) will provide free training for the operators and maintenance people, in Buyer's factory. e. If the Buyer does not request commissioning by our engineer(s) within four months from the date of the bill of lading, it will be accepted that all the equipment has been successfully tested and approved by the Buyer. |

| Quantity and quality guarantee |

| a. In cases of quantity discrepancies or equipment damage, at the destination, the Buyer will file a claim within 30 days after the arrival of the goods at its destination. The insurance company and the shipping company will be responsible for all discrepancies and damage caused by the shipping company or other transportation companies. b. Guarantee period and after-sales services: 13 months from the date of the bill of lading. During this guarantee period, if there is a quality issue, we will provide spare parts without charge. If malfunctions are caused by the Buyer's improper operation of equipment, we will provide the Buyer with spare parts at cost prices. c. Long-term service: Beyond one year, we will provide the Buyer with spare parts at reasonable prices and provide long-term technical guidance. |