Waste Plastic Pelletizing Granulating Machine with No Mesh Screen Changer

Zhangjiagang Plastar Machinery Co., Ltd.- After-sales Service:Engineers Available to Overseas

- Warranty:1 Year

- Material Processed:Film

- Plastic Type:PE

- Screw:Single-Screw

- Automation:Automation

Base Info

- Model NO.:PL

- Computerized:Non-Computerized

- Certification:ISO9001:2008, CE

- Applicable Plastic:PP, PE, LDPE, HDPE, ABS, EPS, PC

- Type:Recycling Granulator

- Screw Design:Single Screw

- Function:Recycling & Pelletizing Waste Plastic

- Capacity:100-1500kg,H

- Voltage:220V, 380V, 440V etc

- Used for:Plastic Pelletizing Extruder

- Feeding Type:Force Feeder & Compactor Type

- Cutting Type:Water Ring & Noddle Strip

- Color:Customizable

- Name:Plastic Recycling Pelletizing Machine

- Main Motor:Siemens Beide

- Air Vent Design:Natural Air Venting,Vacuum Degassing

- Screw Diameter:85mm, 90mm, 100mm, 120mm, 150mm,200mm

- Transport Package:Plastic Pelletizing Extruder Is Packed by Wood

- Specification:4300*2000*2000

- Trademark:plastar

- Origin:China

- HS Code:8477800000

- Production Capacity:100sets,Year

Description

Basic Info.

Model NO. PL Computerized Non-Computerized Certification ISO9001:2008, CE Applicable Plastic PP, PE, LDPE, HDPE, ABS, EPS, PC Type Recycling Granulator Screw Design Single Screw Function Recycling & Pelletizing Waste Plastic Capacity 100-1500kg/H Voltage 220V, 380V, 440V etc Used for Plastic Pelletizing Extruder Feeding Type Force Feeder & Compactor Type Cutting Type Water Ring & Noddle Strip Color Customizable Name Plastic Recycling Pelletizing Machine Main Motor Siemens Beide Air Vent Design Natural Air Venting/Vacuum Degassing Screw Diameter 85mm, 90mm, 100mm, 120mm, 150mm,200mm Transport Package Plastic Pelletizing Extruder Is Packed by Wood Specification 4300*2000*2000 Trademark plastar Origin China HS Code 8477800000 Production Capacity 100sets/YearProduct Description

Average lead time -one month

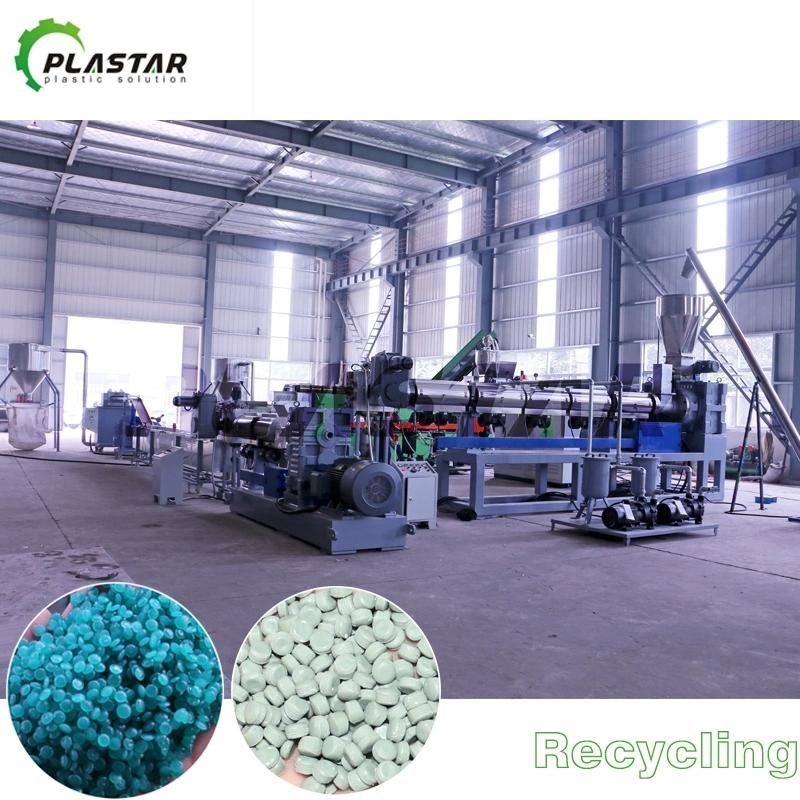

Waste PP PE Bag Plastic Pelletizing Granulation Machine

Description:

1. This PP PE Bag Pelletizing line Granulating Machine line can process recycled PP PE film and turn them into PP PE granules.

2. The granules are cutted in the water which make the granules smoothly and rounded, which can command a higher price in the market.

3. It adopts Japanese technology for automatic temperature control.

4. It's easy to operation, stable working and excellent quality, making it your first choice for plastic recycling.

Product Description

PP PE plastic pelletizing production line is used to make pellets from waste plastics, like PP, PE films, or HDPE, PP flakes or PET flakes.

For plastic PP, PE films, we developed a compact pelletizing line for them. Due to the films are very soft and foamed, it's difficult to be filled into extruder directly, even by force feeder screw, the efficiency is not good, and can be blocked. So, we integrated the most advanced technologies and cost-effective concepts for this kind of machine, we developed the PP, PE film granulating machine.

Features

1. All recycling materials after sorting, crushing, and washing, no need spin-drying, or oven drying, or drying in the sun, can be used to produce. This plastic pelletizing line is applicable for both dry and wet materials.

2. It is full automatic from raw materials crushing, washing, feeding to pelletizing.

3. It takes full advantages of high pressure friction ceaseless temperature increasing system to heat, avoiding continuous heating, which is energy saving.

4. It adopts separate and full automatic power distribution system to ensure motor running under safe and normal condition.

5. Screw and barrel is made of high strengthened carbon steel, which has long using life.

Application

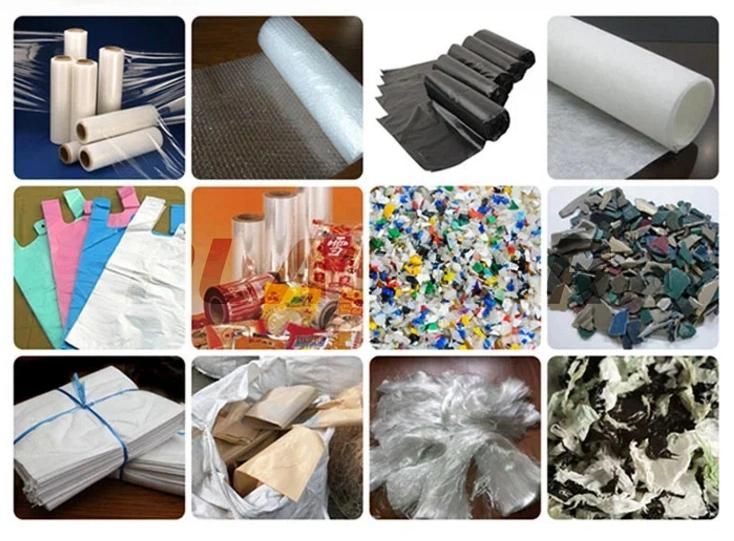

PP PE film plasticpelletizing production line is mainly used to make pellets from waste plastics, like PP, PE films, agricultural films, LDPE stretch films, LLDPE films, PP woven bags, shopping bags, and other soft PP,PE plastics.

Processing capacity is from 100kg/h to 1500kg/h.

Suitable raw material:

After recycling pelletizing machine:

Machine pictures for reference:

No mesh screen changer

Customer visting:

Machine package&shipping:

Zhangjiagang Plastar Machinery Co., Ltd. is a professional manufacturer for kinds of plastic machines, such as plastic pipe extrusion line, plastic profile extrusion line, waste plastic recycling machine, plastic crusher & Shredder and plastic process auxiliary machines, etc.

The target of Plastar Machinery Co.,Ltd is to offer the best quality machines to the customers from all over the world. With the advanced technology, experienced engineers and skilled workers, we have the capability to manufacture specific machines according to customer's requirement.

Excellent quality and professional service is the promise made by Plastar Machinery Co.,Ltd to new and old friends. We are looking forward to establish good cooperation relationship with you on the basis of mutual benefits.