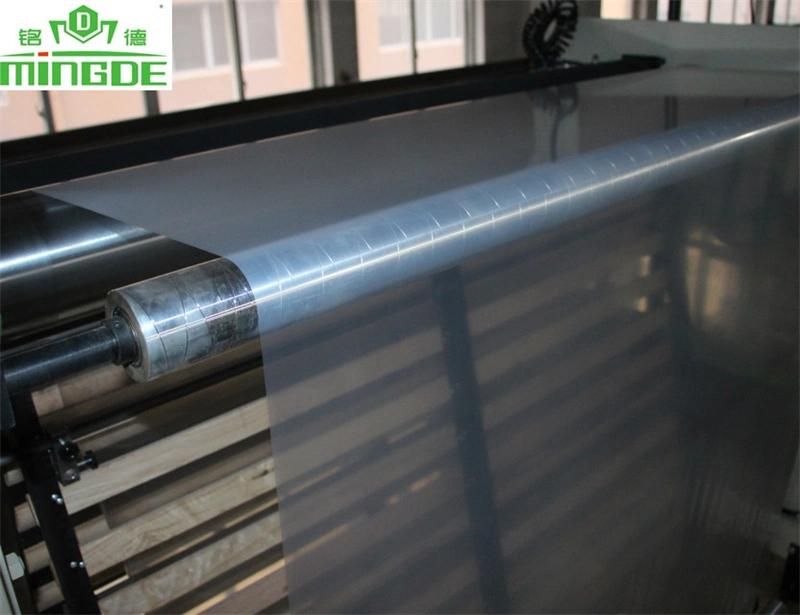

Mingde High Speed Automatic Plastic LDPE Blown Wide Film Extruder Blowing Machine

Ruian Mingde Machinery Co., Ltd.- After-sales Service:Online Support

- Warranty:1 Year

- Type:PE Film Blowing Machine

- Raw Material:LDPE

- Maximum Folding Width of Film:2500mm

- Screw Diameter:100mm

Base Info

- Model NO.:MD-L

- Automation:Automatic

- Computerized:Computerized

- Machine Weight:4T

- Certification:CE, ISO9001:2008

- Film Thickness:Ld:0.015-0.15mm

- Type of Rewinder:Fully Automatic

- Gear Box:250

- Output:280kgs,Hr

- Screw L/D Ratio:30:1

- Die Head:500,600

- Winding Speed(M/Min):5-60

- Transport Package:Wooden Packing

- Trademark:Mingde

- Origin:China

- HS Code:8477209000

- Production Capacity:280kg,Hr

Description

Surface Friction Double WindersRoller Width (mm) 1600 2100 2600 Winding Motor(KW) 16N.M 1.5KW 2.2KW Winding Speed(M/min) 5-60 5-60 5-60 Voltage 380V/50HZ/3PHASE 380V/50HZ/3PHASE 380V/50HZ/3PHASE Cover Dimensins(m) 6.8*2.6*6.5 7.5*3.2*7.5 9.4.2*9

MD-L series High speed film blowing machine set

1. It is used to blowing LDPE, which has been widely used for producing laminating film, packing film, agricultural covering film, bag or film for textile and clothing and other packing material.

2. The main motor adopts frequency control of motor speed to improve the speed regulating stability of main motor and save electricity by 30%.

3. The screw and barrel adopt 38 chrome-molybdenum aluminum which has been nitrogen treated and the traction frame adopts lifting type. No matter what size the film is, big or small, it can achieve the best effect of cooling.

Optional equipment

Double winder

Rotary die head

Auto loader

Double lip air ring

Air shaft

Corona treatment

Fast screen changer

Air compressor

All roller pneumatic type

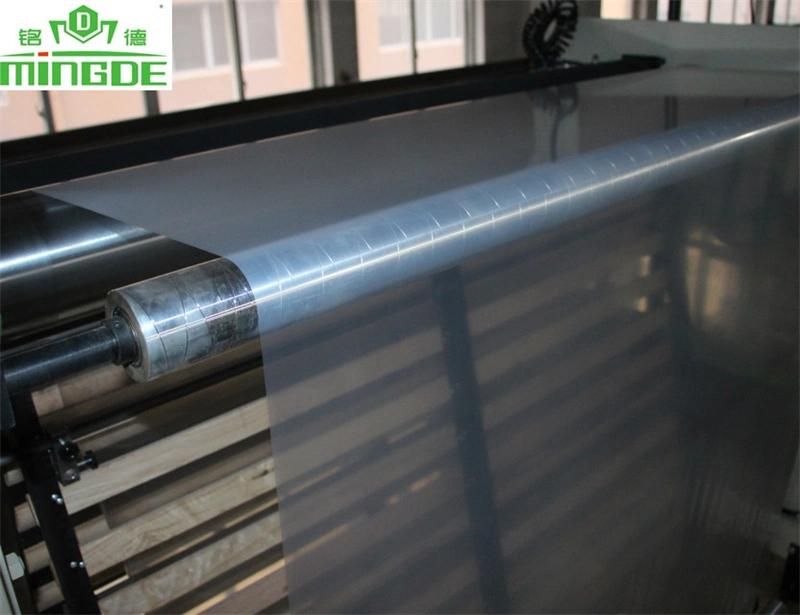

MD-L series High speed film blowing machine set

1. It is used to blowing LDPE, which has been widely used for producing laminating film, packing film, agricultural covering film, bag or film for textile and clothing and other packing material.

2. The main motor adopts frequency control of motor speed to improve the speed regulating stability of main motor and save electricity by 30%.

3. The screw and barrel adopt 38 chrome-molybdenum aluminum which has been nitrogen treated and the traction frame adopts lifting type. No matter what size the film is, big or small, it can achieve the best effect of cooling.

Optional equipment

Double winder

Rotary die head

Auto loader

Double lip air ring

Air shaft

Corona treatment

Fast screen changer

Air compressor

All roller pneumatic type