Factory Based PA66/PA6/PA Glass Fiber Reinforce Plastic Extruder Machine

Nanjing Kairong Machinery Tech. Co., Ltd.- Type:Granules Extruder

- Plastic Processed:PP

- Product Type:Granulating Extruder

- Feeding Mode:Multiple Feed

- Assembly Structure:Separate Type Extruder

- Screw:Twin-Screw

Base Info

- Model NO.:TSE-75

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Color:as Require

- Transport Package:Wooden Cases

- Specification:as require

- Trademark:haisi

- Origin:Jiangsu

- Production Capacity:300sets Per Year

Description

Basic Info.

Model NO. TSE-75 Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Color as Require Transport Package Wooden Cases Specification as require Trademark haisi Origin Jiangsu Production Capacity 300sets Per YearProduct Description

PA glass fiber reinforce co-rotating twin screw extruder machine

Application

TSE-75 twin screw extruder is suitable for :

Compounds: PP/PA/PBT/ABS/AS/PC/POM/PPS/PET + glass fiber/carbon fiber ;

PC+ABS/PA+ABS/CPE+ABS/PP+EPDM/PA+EPDM/PP+SBS;

Masterbartches with Flame-retardants:PE/ABS/PS/EVA/PET/PP,etc. With flame retardants and other additives;

Features

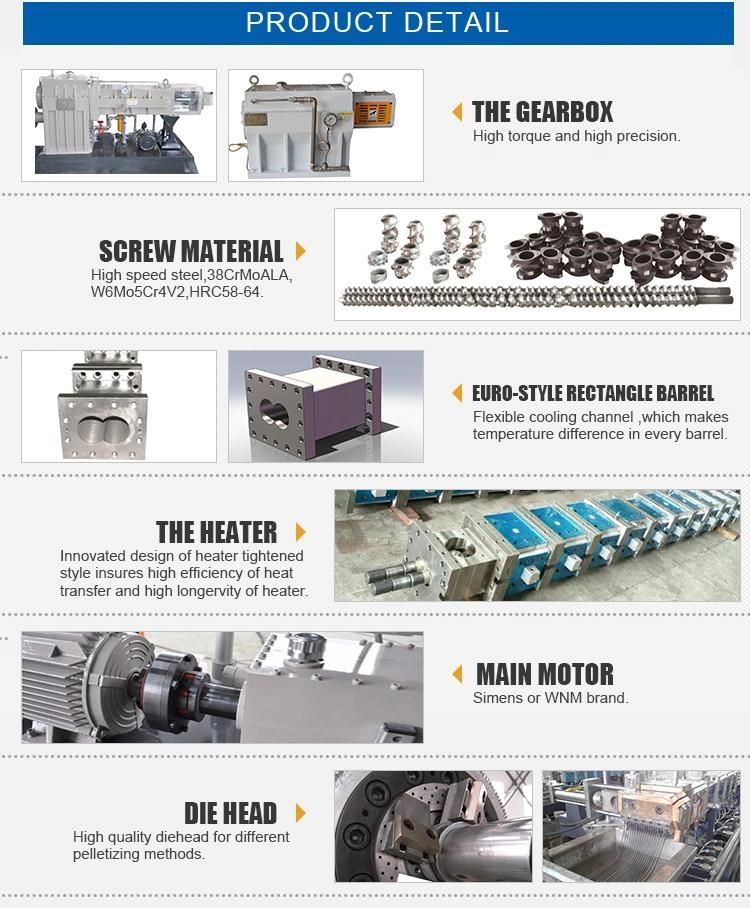

The screw is made of high tool steel 38 CrMoALA or W6Mo5Cr4V2. Special screw combination

euro-style rectangle barrl, reflux refrigeration channel is optimized and disposed,which makes temperature difference in D areas smaller.

innovated design of heater tightened style insures high efficiency of heat transfer and high longevity of heater.

the material is used high quality nitrided steel ,corrosion proof or antifriction with correspounding processed

new-style project of parallel three-axises driving makes the conve axis,convey

chain,decelerate and torque get together ,which keep it compact ,and the key bearings are imported

soakage and spraying lubriation integrate smoothly

technics,strengthening of tooth face,so they can ensure high torque,high precision and low noise

the selecte material of drive components is dainty,including super intention alloy cementiteing steel,cementiting and grinding.

frame structure control cabinet

imported electrical elements

imported temperature control system

imported driving system

interlock and multi-protection

adopting imported PLC(OMRON or SIMES) to achieve optimized process control.Stronger function,steady performance and much higher accuracy.

it can be also accomplished full-set link-lock protection,trouble safeguard,fault alarm cluing and so on

operation interface on touching screen is visual and marked ,which is brief and easy to use.

Pelletizing line

Strand pelletizing line

Our company

NAN JING HAISI EXTRUSION EQUIPMENT CO.,Ltd is a high-tech company specializing in R&D design,manufacturing technique,sales service and basing on extruder industry for many years.we are now mainly devoted to highly active single,twin screw and compounding extruders, at the same time completely plant manufacture and interrelated technics,until turn-key project.

Our production series contain single screw extruder,co-rotating twin-screw compounding extruder,auxiliary equipment etc.

High quality service is our promises forever!

| Mode | Screw Diameter D(mm) | L/D | Screw Rotation N( r/min) | Main Power P ( kw) | Screw Torque T(N.m) | T/N3 | Output Q (kg/h) |

| TSE-30B | 31 | 32-48 | 600 | 15 | 119 | 6.7 | 5-40 |

| TSE-35B | 35.6 | 32-52 | 600 | 15-22 | 119 | 4.4 | 20-60 |

| TSE-40B | 41 | 32-52 | 600 | 30 | 239 | 5.8 | 90-150 |

| TSE-50B | 50.5 | 32-52 | 500 | 45-55 | 430 | 5.4 | 135-270 |

| TSE-65B | 62.4 | 32-64 | 600 | 90 | 716 | 5.1 | 200-300 |

| TSE-75B | 71 | 32-64 | 600 | 132 | 1050 | 4.8 | 350-550 |

| TSE-75D | 71 | 32-64 | 600 | 200-250 | 1990 | 9.2 | 500-1000 |

| TSE-95B | 93 | 32-64 | 600 | 315 | 2506 | 5.3 | 800-1200 |