1050mm PVC and ASA Roofing Sheet Extrusion Line

Qingdao Weier Plastic Machinery Co., Ltd.- Product Type:PVC Board

- Board Layers:Multilayer

- Screw No.:Double-screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008, UL, QS, GMP

Base Info

- Model NO.:SJSZ-80,156

- Customized:Customized

- Condition:New

- Machine Name:PVC and ASA Roofing Sheet Line

- Capacity:250-400kg,Hr

- Contactor:Siemens

- Install Power:165kw

- Control System:PLC Control System

- Material:PVC +ASA+ Chemical Additives

- Thickness of Roofing:2-3mm

- Power Supply:380V 3phase 50Hz

- Operator:2-3person ,Shift

- Warranty:12monthes

- Transport Package:PE Elastic Film or Wooden Case

- Specification:As per customer′s request

- Trademark:WEIER

- Origin:Qingdao China

- HS Code:84772090

- Production Capacity:25sets,Year

Description

Basic Info.

Model NO. SJSZ-80/156 Customized Customized Condition New Machine Name PVC and ASA Roofing Sheet Line Capacity 250-400kg/Hr Contactor Siemens Install Power 165kw Control System PLC Control System Material PVC +ASA+ Chemical Additives Thickness of Roofing 2-3mm Power Supply 380V 3phase 50Hz Operator 2-3person /Shift Warranty 12monthes Transport Package PE Elastic Film or Wooden Case Specification As per customer′s request Trademark WEIER Origin Qingdao China HS Code 84772090 Production Capacity 25sets/YearProduct Description

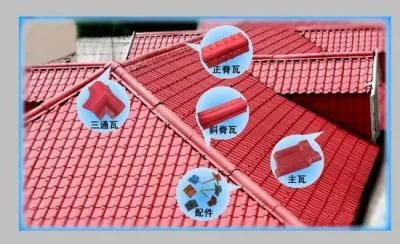

1050mm PVC and ASA Roofing Sheet Extrusion Line with 18 Years FactoryPVC and ASA roofing sheet applications:Wave plate has an excellent corrosion resistance, weather resistance, easy processing, low cost and many other characteristicsm abd is widely used for roof material of workshops, warehouses.

Equipment lists

Equipment lists| 1.1)Screw loader for SJZ 80/156 extruder | |

| 1.2) Conical twin screw extruder | SJSZ-80/156 |

| 1.3) Vacuum feeder and drying hopper | STG-75 |

| 1.4) Single screw extruder(ASA layer) | SJ-65/30 |

| 1.5) Mold and distributor | PM1000 |

| 1.6)Two roller embossing calendar | YH-1200 |

| 1.7)Temperature controller | |

| 1.8) Roof forming unit | ZSW-900 |

| 1.9)Cutting unit | QG-1000 |

| 1.10)Stacker | LJ-6000 |

1.1)Flat sheet haul-off unit

1.2)Oven

1.3)Ridge tile forming unit

1.4)ridge tile mold (4sets)

Summarization

| Materials | PVC,ASA with different colors and some additives |

| Products width | 880mm/1050mm |

| Products thickness | 2-3mm |

| Center meter | 1100mm |

| Products color | decide by customer |

| Output | 350-400kg/hr ;1000m2 per 24 hours |

| Line speed | 0.3-4M/min |

| Operation direction | from right to left |