PVC / WPC Wood Composite Crust / Celuka / Skinned Foam Board /Panel/ Sheet /Plate Extruder ...

QINGDAO DING KUN PLASTIC MACHINERY CO., LTD.- Warranty:1 Year

- Product Type:PVC Board

Base Info

- Model NO.:SJSZ80

- Board Layers:Multilayer

- Screw No.:Double-screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008

- Customized:Customized

- Condition:New

- Extruder Model:Sjsz 80,156

- Capacity:380kgs,Hour

- Machine Sizes:30, 000X2, 700X2, 500mm

- Raw Material:PVC Powder, Wood Powder, Additives

- Main Motor:55kw

- Weight:28 -30tons

- Width of Board:1220mm, 1560mm, 2050mm

- Thcikness of Board:3mm to 30mm

- Core Components:Motor, Pump, PLC, Pressure Vessel, Engine, Gearbox

- Voltage:380V-440V

- Control System:Siemens PLC

- Motor:Siemens

- Inverter:ABB

- Temperature Meter:Omron

- Contactor:Siemens

- Transport Package:Export Standard

- Specification:CE

- Trademark:DINGKUN

- Origin:Qingdao

- HS Code:8477209000

- Production Capacity:320-400kgs,Hour

Description

Product Description

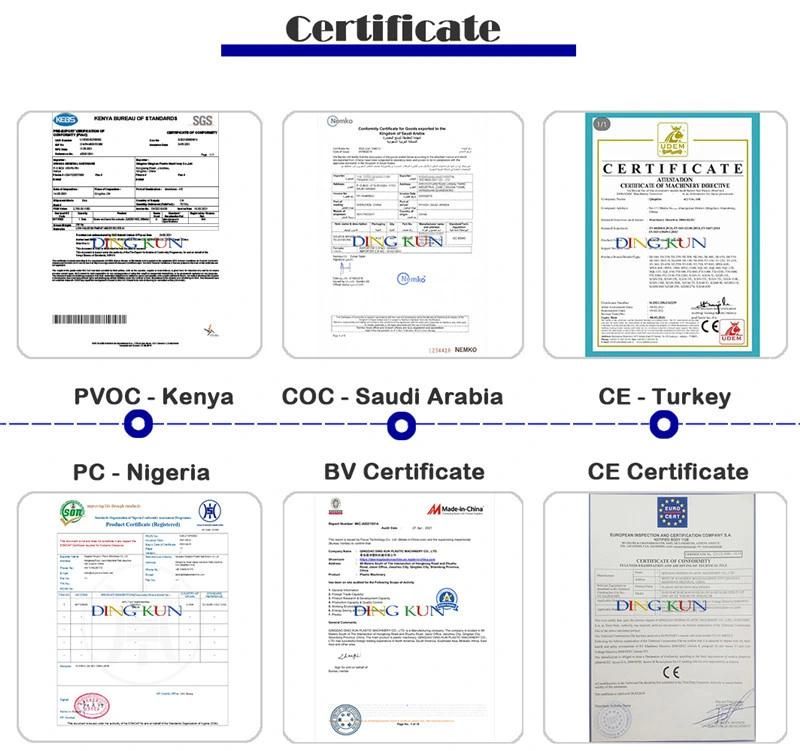

Detailed Photos Application Packaging & Shipping Certifications Certification Certified By Certificate No. Business Scope Expiry Dat ISO 9001:2008 Beijing Hangxie Certification Design and Production of CE European CN.CE.0680-10/10 Plastic Extrusion Machinery & TUV TÜV Rheinland 7467484_P+T Production & Trade Assessment Main Product Lines Verification Report TÜV Rheinland 7467487_P+T Main Product Lines Verification SGS SGS-CSTC Standards Technical Services Co.,Ltd Focus Technology Co., Ltd QIP-ASR155278 Extrusion Machine, Pipe Machine ,profile Machine, Roof Machine… FAQ 1. Quality Control Management Q: Is there quality control on all production lines? A: Yes, all production lines have adequate quality control Q: Do the QA/QC inspectors work independently from the production line? A: Yes Q:How many QA/QC inspectors in total? A: 4 Q: Number. of Employees in Each Production Line A: Supervisor 1 ; No. of Operators 29 ;No. of In-line QC/QA 2 2.Supplier Management Q:Does the company have a supplier assessment procedure? After Sales Service 1.We will provide the Feasibility Analysis Report for the wood-plastic project. Now we have machines in stock,sincerely invite you to vist our factory! Also you can contact me for machine's running video. Company Profile

Auxiliary Machines for your choice1 SHRL500/1000 Mixer 1set 2 SWP-400 Crusher 1set 3 SMP-500 Miller 1set 4 Water Chiller 1set

Center Co., Ltd.,

CNAS

03413Q21640R1M

Single-Screw Plastic Extruders

and Conical Twin-Screw

Plastic Extruders

Inspection and

Certification

Company S.A.

SJ-30, SJ-45, SJ-65, SJ-90,

SJ-120, SJ-150, SJ-180,

SJ-200, SJSZ-51/105,

SJSZ-65/132, SJZS-80/156,

SJSZ-92/188

A:Yes

Q:Does the company have an updated list of approved suppliers?

A:Yes

Q:Does the company establish and implement a standard procedure for purchasing contract review and approval?

A:Yes, with written standard procedures

Q:Does the company keep its supplier assessment reports?

A:Yes, with written standard procedures

Q:Does the company keep its supplier assessment reports?

A:Yes, assessment reports are available for the last 1-3 years

Q:Are the company's purchasing documents sufficient to ensure product safety control and their customers' requirements?

A:Yes, the purchasing document includes all the information required

Q:Is there a procedure to conduct random product inspections after final packaging?

A:Yes, with clear standard and written inspection records

2.We will provide the model selection and technical parameter for wood-plastic machinery.

3.We will provide the design for the plant and electric power accounting for the facilities.

4.We will provide the design for wood-plastic formula according to the product requirements.

5.We will provide the technology of wood-plastic product surface treatment

6.We will provide technique training for operator.

7.We will provide solution for the practical problem during the production.

8.We will install and test the machine for free.

9.We will provide turnkey project to customers.