Full Auto Plastic Pet Bottles Granules Making Machine/Pet Flakes Pelletizer Machine/Waste ...

Zhangjiagang Jorbin Machinery Co., Ltd.- Warranty:1 Year

- Raw Material:PET

- Screw:Double-Screw

- Inverter:Inverter

- Electromagnetic Heater:Electromagnetic Heater

- Automation:Automatic

Base Info

- Model NO.:TSSK65

- Computerized:Computerized

- Customized:Customized

- Certification:CE, SGS

- Condition:Used

- Capacity:50-600kg,H

- Screw and Barrel:38CrMoAl, Nitrogen, Bimetallic

- Application:Pet Bottle Recycling

- Degassing:Roots Vacuum

- Pelletizing Way:Pull Strap(Like Noodles)

- Delivery Time:45 Working Days

- Extruder:Co-Rotating Twin Extruder

- Cooling Way:by Water

- Heater:Cost Al or Cost Copper

- Ld:36:1

- Certifcate:CE

- Feeder Way:Single Screw Feeder

- Dryer:Crystallization Dryer

- Screw Diamter:35-95mm

- Transport Package:Film Packing and Wood Base or Wood Case

- Specification:pellets size Φ 2.5*3mm

- Trademark:JORBIN

- Origin:Zhangjiagang City

- HS Code:84772010

- Production Capacity:10sets,Year

Description

Model

TSSK20

TSSK30

TSSK35

TSSK50

TSSK65

TSSK72

TSSK92

Screw diameter(mm)

21.7

30

35.6

50.5

62.4

71.2

91

Rotary speed(rpm)

600

400

400/600

500/600

400/500

400/500

400/500

Main motor power(kw)

4

11

11/15

37/45

55/75

90/110

220/250

L/D

32-40

28-48

32-48

32-48

32-48

32-48

32-40

Capacity(kg/h)

2-10

5-30

10-80

20-150

100-300

300-600

600-1000

Layout of the machine

More details machine photoes

Crystallization dryer: dryer the PET flakes in advance

Vulume: 1000L.

Heater power: 36kW

Heat way: by electric

Blower power : 4kW

Mixer power: 2.2kW

Mixer shaft: SS304

Material: Inside stainless steel, outside A3, With warm insulation layer.

With the open door on the hopper, it will be easily operate.

Single screw feeder For feeding the flakes into the extruder:

Feed the PET flakes into the extruder, single screw feeder, feeding the material equally and stably.

Horizontal screw parameter:

Screw diameter:φ60

Power:1.5kw

Material of hopper: SS304

There is sight glass on the hopper, worker can be see the material in the hopper

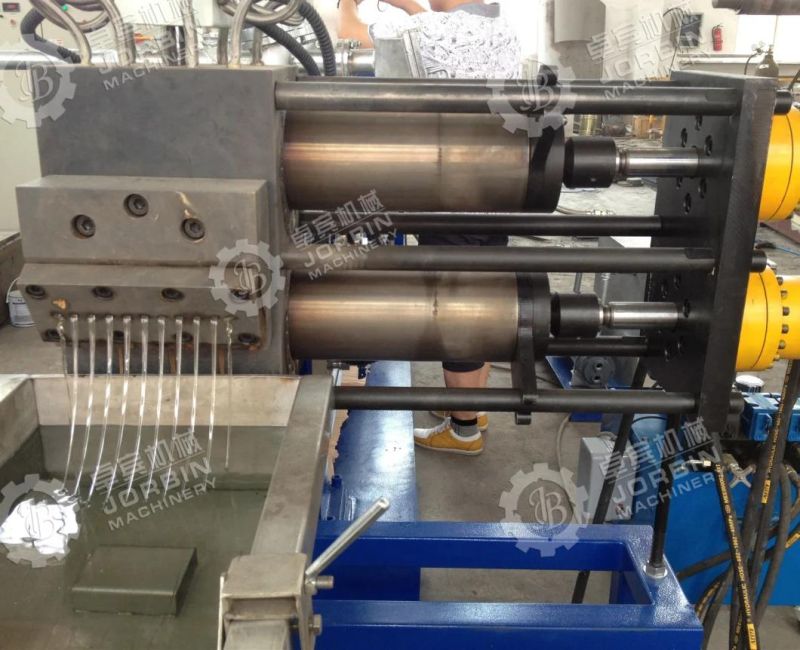

Twin screw extruder machine

Barrel number: 10

Length of barrel #1-10 is 234mm

Total length of barrels: ~2340mm

Barrel #1-9 made of 38CrMoAl material, Hardened to ≥61HRC

The barrel section are cooled with water, each barrel adopts single throttle and solenoid valve, and solenoid valve imported from Italy.

Barrel#1 open for feeder, Barrel#4: open barrel, for natural degassing, Barrel#6, Barrel#68: open barrel, for vacuum degassing. The others is closed.

The processing section is provided with stainless steel cover as a protection against.

Diameter :62.4 mm L/D: 36:1

Centre distance: 52mm

Material of screw: W6Mo5Cr4V2

Rotating speed (counter rotating): 400RPM

A pair of screw shafts, complete with screw elements, screw shafts material is 40CrNiMo, Hardened to ≥61HRC

The material come out from the die(pull trap like noodles pelletizing way, PET must use this pelletizing way. And the its need good vacuum, like roots pump, then the pellets will be much better)

Cooling for the screw( water controlled by electric valves)

Screw elements of the machine

Vacuum, we can use Roots vacuum or Bipolar pump.

Degassing on the extruder

Water tank

Material come from the die and go into the water tank for cooling, There is rubber roller in the tank, material strap can be send into gale dryer to blower the water on its surface.

Length of tank : 4m,

Material of tank is SS304, Material of bracket :Q235

It Can be moved up and down, forward and back up to the die and material needed.

Power of blower on gale dryer:2.2kW

Pelletizer

A. Portal shaped type pelletizer,horniness alloy rotary cutter

B. capacity:300kg/hr

C. motor power:4KW

D. Cutter diameter: 300mm

E. Blade width: 20mm

F. Traction speed :30-90m/min

G. No. of cutter gears: 32

H. Max number of lines: less than 60

Final pellets and Raw material

If you need more details of this kind of machine kindly contact me, I can send you more detail photoes and vedios.

1. We supply below necessary documents with the machine:

- Machine layout

- Electricity diagram

- Machine certificate

- General manual book/maintenance book

2. We provides one-year quality guarantee. During this period, if the machine's malfunction is approved to be our responsibility, we will send the broken spare parts to you with DHL courier or other way within 7 workdays after receiving the complainant. And send the technicians to the buyer's factory for maintaining. All charges are in our account.

3. After one year guarantee, If you need we can provides payable spare parts and technician's VISITING maintenance, and any broken spares we can send you soon as possible.

4. We trust that our quotation meets with your requirements and we will gladly furnish you with further information.

5. 24Hours service : Cell+86-13915707468