Plastic Recycling Machine/ Plastic Palletizing Machine Brick with Pull Strap Granulate Way ...

Zhangjiagang Jorbin Machinery Co., Ltd.- After-sales Service:24 Hours

- Warranty:1 Year

- Raw Material:PP

- Screw:Double-Screw

- Inverter:Inverter

- Electromagnetic Heater:Electromagnetic Heater

Base Info

- Model NO.:ML85-85

- Automation:Automatic

- Computerized:Computerized

- Customized:Customized

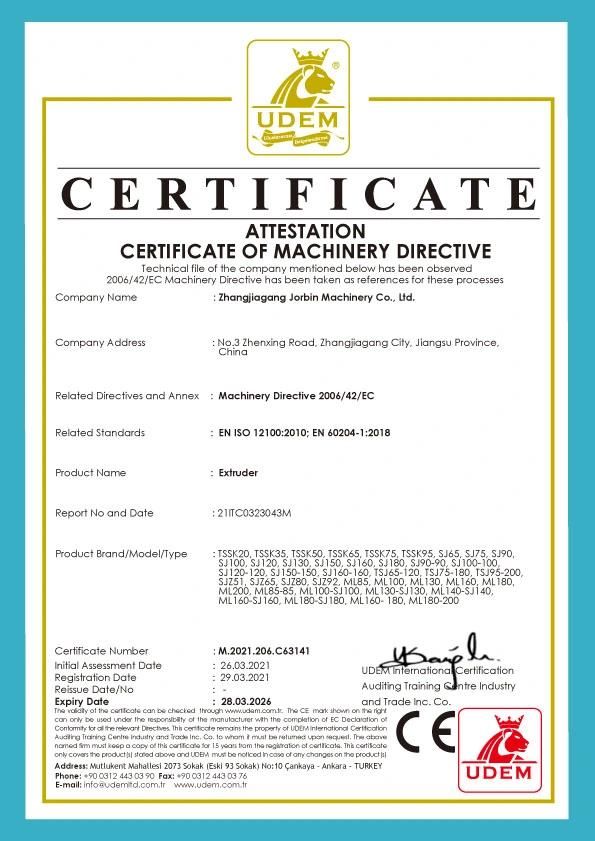

- Certification:CE, SGS

- Condition:New

- Capacity:550-650 Kg,H

- Screw and Barrel:38crmoala, Nitrogen, Bimetallic

- Application:PP Woven Bag

- Degassing:Two(One Vacuum, One Natural)

- Pelletizing Way:Pull Strap Like Noodles

- Delivery Time:45 Working Days

- Extruder:Double Stage

- Cooling Time:by Water

- Heater:Cast Al

- L/D:28-10

- Motor:Siemens

- Speed Control:by Inverter

- Screen Changer:Double Filter

- Certifcation:CE SGS

- Function:Recycle Granules Making

- Transport Package:Film Packing and Wood Base or Wood Case

- Specification:Pellets size: 2.5*3 mm

- Trademark:JORBIN

- Origin:Zhangjiagang City

- HS Code:84772010

- Production Capacity:10 Sets,Year

Description

Motor power

Final pellets

Plastic Recycling Machine/ Plastic Palletizing Machine Brick with pull strap granulate way market

PP woven bag double stage extruder with pull strap (like noodles)

Two stage film recycing pelletizing machine/Waste BOPP PP woven bag recycling granulation machine/HDPE film recycling pelletizing machine,with Compactor is mainly used for PA, PP, PS, PE, EPE, EPS,PET,UPS,ABS Film etc.

The advantages of this machine

1. Highly efficent: the machine is automatic and with less power consumption.

2. Special screw design: We will design the screw up to customer different material and the material of screw and barrel can be 38CrMoAL or bimetallic.

3. High capacity: the capacity of the machine is about 200kg/h

4. Material come out more stably: material go through from the first stage to the second stage, with two screen changers, much more impurity will be filterd and the material come out from the die won't be broken down.

5. Beautiful pellets: two degassing systems, no air in the pellets.

6. The machine with long life.

Machine Introduction--Compactor

The advantages of the compactor

1. Counter current technology

Hight process stability thorugh improved material intake ensures constantly high output over a considerably broader temperature rang;

Higher flexibility and operational reliability with a variety of materials;

Increased throughputs with the same plant size for more productivity;

2. Smart Start

Remarkably easy operate thanks to logical, clearly structured and simplified handing and ultramodern ergonomiic touchscreen disply;

Fewer buttons, more user-friendliness-thanks to high degree of automat on including extensive control packages;

The right recipe for every application-saved processing paramerter can be loaded easily and conveniently from the recipe management system at the push of a button;

3. Save

Lower specific energy requirements thanks to a complete package featuring design and process engineering measures including the new direct drive for the extruder screw;

Lower production costs through optimised control technology and high-quality, energy-efficient components such as high-performance motors;

Additionally, the parctical energy dispaly on your operating panel gives you a constant overvies of eenergy consumption at all times, thus enabling

you to take specific measures to optimise consumption;

Environmental protection;

Machine Introduction--extruder

Function: Material come from the first stage into the second stage through the die, this is pull strap pelletizing way.

The advantages of twin stage machine:

1. two screen changers can filter more impurity, the pressure can be reduced.

2. the capacity can be improved.

3. Material come out from the die will be much more stable, won't be broken down.

Material come from the first stage into the second stage

Pull strap pelletizing way which like noodles, we also can make water-ring hot die face pelletizing way, wind cooling hot die face pelletizing way. This can be customized.

Water tank ,dryer, silo is also used on the line to dry and collect the pellets.

We use Cast Al heater on the machine , and there are cast copper,China, different material the heater can be different

We use Cast Al heater on the machine , and there are cast copper,China, different material the heater can be different

Certification display&our customers

1. We supply below necessary documents with the machine:

- Machine layout

- Electricity diagram

- Machine certificate

- General manual book/maintenance book