Automatic Extrusion Blowing Blow Molding Moulding Machine for Making Plastic HDPE PP PETG ...

Zhangjiagang Sino-Tech Machinery Co., Ltd.- Type:Extrusion Blow Molding Machine

- Automatic Grade:Automatic

- Warranty:One Year

- Made in:China

- Application:Plastic Bottle, Jerry Can, Plastic Product

- Dimension(L*W*H):6.8*6.4*3.6m

Base Info

- Model NO.:STS-15L

- Delivery Time:60 Days After Payment

- Mould:One,Two,Three,Five,Six Cavity

- Station:Double Station

- Weight:25 Tons

- Water Consumption:100 L,Min

- Blowing Pressure:0.8 MPa

- Raw Material:HDPE

- Making Method of Parison:Extrusion-Blow Molding

- Automation:Automatic

- Computerized:Computerized

- Certification:CE

- Transport Package:Wooden Case

- Trademark:Sino-tech

- Origin:Jiangsu, Zhangjiagang

- HS Code:8477301000

- Production Capacity:200 Sets,Year

Description

Basic Info.

Model NO. STS-15L Delivery Time 60 Days After Payment Mould One/Two/Three/Five/Six Cavity Station Double Station Weight 25 Tons Water Consumption 100 L/Min Blowing Pressure 0.8 MPa Raw Material HDPE Making Method of Parison Extrusion-Blow Molding Automation Automatic Computerized Computerized Certification CE Transport Package Wooden Case Trademark Sino-tech Origin Jiangsu, Zhangjiagang HS Code 8477301000 Production Capacity 200 Sets/YearProduct Description

HDPE Bottle Making Machinery/Plastic Jerrycan Extrusion Blow Molding Machine

Technical Specification

| Max.Product Volume(L) | 15 |

| Station | Double |

| Dry cycle (PC/H) | 800*2 |

| Screw Diameter (MM) | 100 |

| Screw L/D Ratio (L/D) | 28 |

| Screw Drive Power (KW) | 75 |

| Screw Heating Power(KW) | 9.1 |

| No.Of heating zone(Srew) | 5 |

| Output of HDPE(kg/h) | 200~500 |

| Hydraulic pump driving power (KW) | 30 |

| Clamping force(KN) | 220 |

| Platen distance (MM) | 320~700 |

| Max.Size of Mold(W*H)(mm) | 750 |

| Central distance of Bi-head(mm) | 250 |

| Max.Die Diameter (Bi-head)(mm) | 140 |

| Max.Die Diameter(single-head)(mm) | 220 |

| Die heating power(single-head)(KW) | 2.6 |

| No.Of heating zone (Bi-head)(ZONE) | 5 |

| Blowing pressure(Mpa) | 0.8 |

| Heating power(Bi-head)(KW) | 5 |

| Air consumption(m³/MIN) | 2 |

| Cooling water pressure(Mpa) | 0.3 |

| Water consumption | 100 |

| Size of machine(L*W*H)(m) | 6.8*6.4*3.6 |

| Weight of machine(TON) | 25 |

Detailed Description

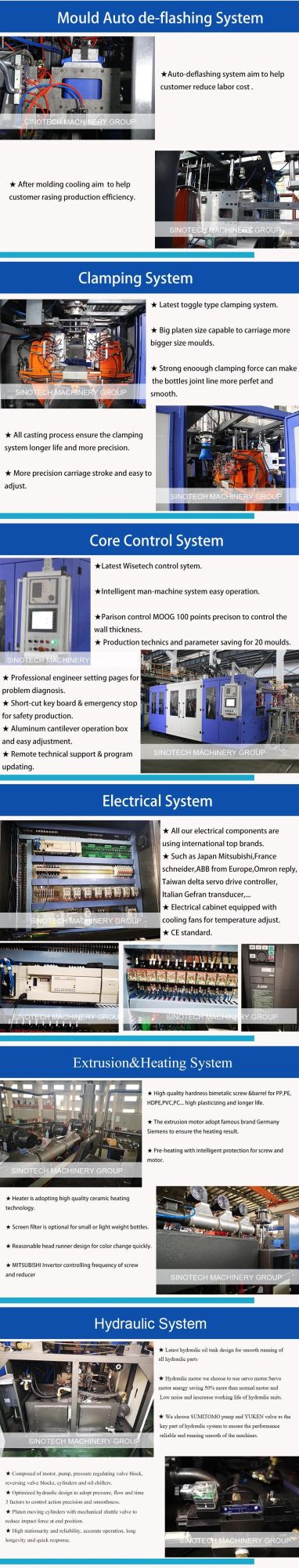

1. Electronic control system: Japanese mitsubishi PLC computer and human interface (Chinese or English) control, color touch operation screen operation, modular temperature empty basin.

All process Settings, changes, retrieval, monitoring, fault diagnosis and other functions are implemented on the touch screen without point contact working principle and components are durable.

The standard electric control box is rejected, which makes the component operating environment stable and the service life of the equipment is prolonged.

2. Hydraulic system: proportional pressure control, equipped with imported brand hydraulic valve and oil pump, stable and reliable.

3. Plasticization system: high efficiency plasticizing and mixing screw, ensure the plasticization is sufficient and even.

4. Speed regulating system: variable frequency debugging + alloy steel hard tooth surface reduction box, speed adjustment is stable, energy saving, noise low, durable.

5. Opening and closing mode and moving mode system: large beam arm, three-point and center locking die mechanism to ensure long-term use.

The locking force is balanced and not deformed, and adopts the translation mechanism (ball guide rail), with high accuracy, little resistance and fast speed.

6. Blow pin rack: the integral Angle ruler type blow needle rack, stable and unmoved, ensure that the incisions are smooth.

7. The opening and closing die and the sliding mechanism of the locking die are in linear guide rail with the precision of the micrometer.

The positioning precision is high, easy and energy saving, and is loaded with strong and invariable.

Patented products: two - rod, single - cylinder bidirectional synchronous open die center locking mechanism, good product stability.

8. In addition to the embryo system, the independent system shortened the cycle, thus improving efficiency

Detail show

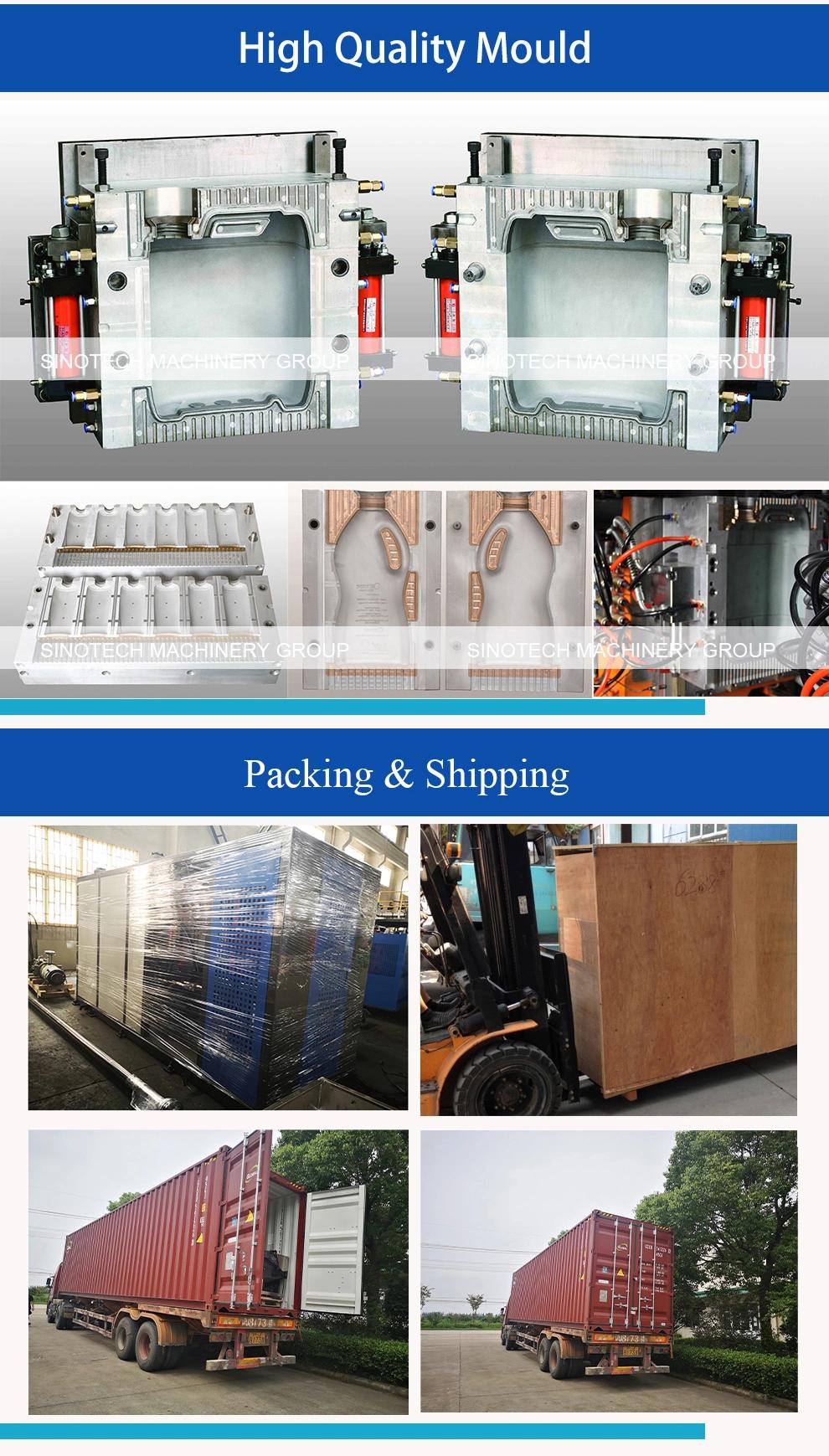

1. The machine body is covered by waterproof film firstly, and then fixed on exported wooden pallets with bolts and wires.

2. The electric controlling parts and spare parts are loaded separately in wooden box.

3. The auxiliary equipments are packaged in wooden box as well.

4. All wooden material is fumigation certificated and safe for exporting to all over the world.

After-sales service

1. We offer you the free machine operation training happened in China.

2. Offering the free testing and installing of the machine in the buyer factory, but the fee of the visa, the ticket, food and living should be in the buyer's charge.

3. The spare parts of the machine and the auxiliary machine can be supply by us.

4. The guarantee of the machine is one year under the normal operation.

5. We offer the customer the technology for free for all life time.

For more info.,please don't hesitate to contact with us!