Waste Plastic Recycling Extruder Plastic Pelletizing Machine

Nanjing Kairong Machinery Tech. Co., Ltd.- After-sales Service:Online Service

- Warranty:1 Year

- Material Processed:Plastic Bottle

- Plastic Type:PE

- Screw:Double-Screw

- Automation:Automation

Base Info

- Model NO.:TSE65

- Computerized:Computerized

- Certification:CE

- Capacity:200-500kg,H

- Screw Design:Double

- Voltage:220V,380V

- Color:Requiremet

- Brand Name:Kairong

- Material:Pet ABS TPU

- Place of Origin:Nanjing,Jiangsu, China (Mainland)

- Transport Package:Wooden Case

- Specification:TSE

- Trademark:kairong

- Origin:Nanjing, Jiangsu

- Production Capacity:200-500kg,H

Description

Basic Info.

Model NO. TSE65 Computerized Computerized Certification CE Capacity 200-500kg/H Screw Design Double Voltage 220V/380V Color Requiremet Brand Name Kairong Material Pet ABS TPU Place of Origin Nanjing,Jiangsu, China (Mainland) Transport Package Wooden Case Specification TSE Trademark kairong Origin Nanjing, Jiangsu Production Capacity 200-500kg/HProduct Description

PET Recycled Plastic Granulator Line Waste Plastic Recycling Pelletizer Machine

Features

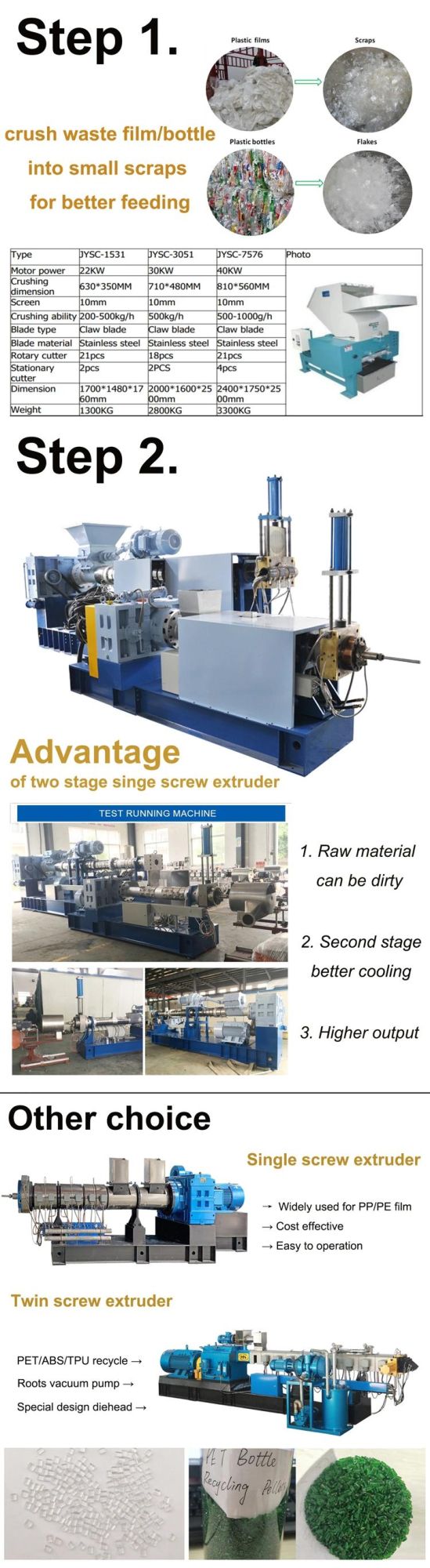

This granulator machine is mainly used to make pellets from waste plastics, like PET Bottle, TPU, PS, ABS waste plastic in factory and other hard plastics.

Processing capacity is from 100kg/h to 500kg/h.

This granulating line is mainly consists of:

1.Belt conveyor: feed the clean films or bags into the cutting compactor

2.Metal detector:check whether there is metal in the films or bags, protect the blades of cutting compact and screws

3.Cutting compactor:cut the materials again and make materials shrink, then force feed the shrunk material into the extruder. For the same capacity, the power consumption is only 50% of the agglomerator.

4.hydraulic screen changer: filter the impurities, improve the granules quality

5.Water cooling tank: use circular water for cooling the granules immediately after pelleting cut.

6.Vibration screen:to filter out non-standard pellets and get even uniform quality pellets.

Technical data

| Mode | Diameter | L/D | N(r/min) | Power(kw) | T(N.m) | Q(Kg/h) |

| TSE-40B | 41 mm | 32-52 | 600 | 30 | 239 | 90-150 |

| TSE-65A | 62.4 mm | 32-52 | 500 | 75 | 716 | 180-270 |

| TSE-75D | 71 mm | 32-64 | 600 | 200-150 | 1990 | 500-1000 |

| TSE-95B | 93 mm | 32-64 | 600 | 315 | 2506 | 1500-2250 |