WPC Wood Plastic Floor Board Machine Extruder (SJSZ80X156) for WPC Outdoor Floor

Qingdao Suke Machinery Co., Ltd.- After-sales Service:24 Hours Working

- Warranty:12monthes

- Product Type:WPC PE Board

- Screw:Single-Screw

- Automation:Automatic

- Computerized:Computerized

Base Info

- Model NO.:SJSZ80x156

- Certification:CE, ISO9001:2008

- Customized:Customized

- Material:Stainless Steel

- Power Supply:380V Three Phase

- Control System:PLC Control System

- Inverter:ABB or FUJI

- Intelligent Temperature Controller:Omron From Japan

- After Sale Service:Life Long with Professional After Sale Team

- Machine Color:as Request

- Contactor:Siemens

- Cooling Method:Recycling Water

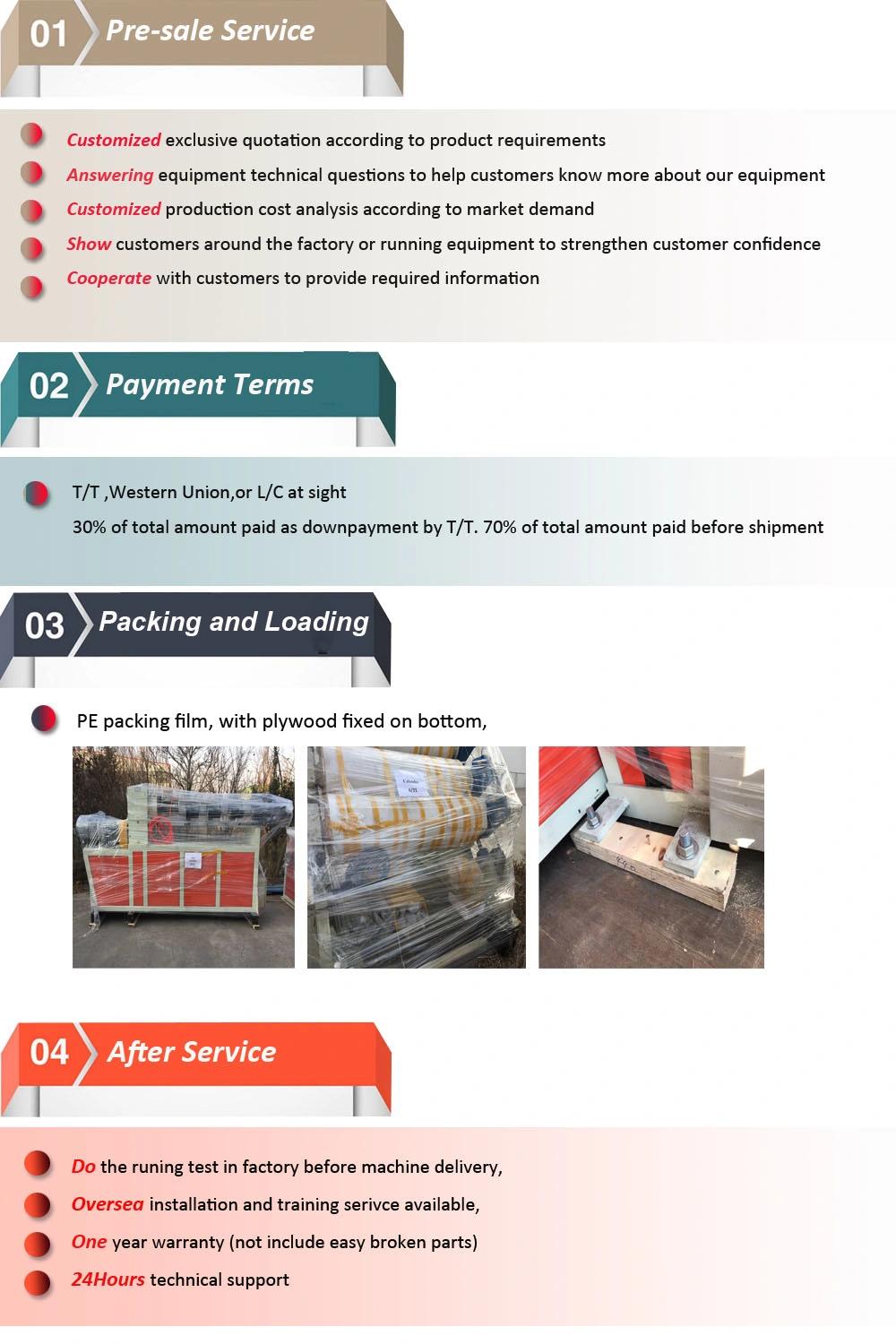

- Transport Package:PE Film and Wooden Package

- Specification:ISO9000 CE

- Trademark:SUKE

- Origin:Qingdao, China

- HS Code:84775900

- Production Capacity:25sets,Year

Description

SJZ65/132SJZ80/156 SJZ92/188 Mian motor power(KW) 22 37 55 110 Drawing height(mm) 150 150 150 150 150 Drawing speed(KN) 20 20 20 30 40 Drawing speed(m/s) 0-5 0-5 0-5 0-3 0-2.5 Auxiliary equipment sum power(kw) 35 35 30 30 40 Cooling water consume(m3/h) 6 6 6 9 12 Compression air(Mpa) 0.6 0.6 0.6 0.6 0.6

WPC Board Machinery Wood Plastic PVC Foam Board Extrusion Line Plastic extruder machine

MACHINE INTRODUCTION:

Our PPVC Wood Plastic Board Extruder Machine uses specially designed conical twin screw extruder to make high quality final products. PVC Wood Plastic Board Extruder Machine uses PVC, wood powder/plant fiber and auxiliary chemicals to produce composite solid board, which is used for interior decoration, furniture, etc.

PRODUCTION PROCESS;

Raw Materials Feeding _ Plasticizing & Extruding _ Shaping by Mould _ Vacuum Calibrating _ Hauling-off _ Cutting _ Stacking

MACHINE DETIALS;

WPC Board Machinery Wood Plastic PVC Foam Board Extrusion Line Plastic extruder machine

MACHINE INTRODUCTION:

Our PPVC Wood Plastic Board Extruder Machine uses specially designed conical twin screw extruder to make high quality final products. PVC Wood Plastic Board Extruder Machine uses PVC, wood powder/plant fiber and auxiliary chemicals to produce composite solid board, which is used for interior decoration, furniture, etc.

PRODUCTION PROCESS;

Raw Materials Feeding _ Plasticizing & Extruding _ Shaping by Mould _ Vacuum Calibrating _ Hauling-off _ Cutting _ Stacking

MACHINE DETIALS;

| Model | SK800 | SK1250 |

| Max. Width of Product(mm) | 800 | 1250 |

| Extruder model | SJSZ80/156 | SJSZ92/188 |

| Max. Extrusion Capacity(kg/h) | 360 | 600 |

| Extruder Power(kw) | 55 | 132 |

| Cooling Water(M3/h) | 13 | 18 |

| Compressed Air(M3/min) | 0.6 | 1 |