PP PS HIPS Thermoforming Sheet Production Line

Qingdao Leader Machinery Co., Ltd.- After-sales Service:Available

- Warranty:18 Months

- Product Type:PP Board

- Board Layers:Single Plate

- Screw No.:Single-screw

- Automation:Automatic

Base Info

- Model NO.:LSJ-90,35

- Computerized:Computerized

- Certification:CE, ISO9001:2008

- Customized:Customized

- Condition:New

- Die Head Design:T-Type or Coat Hanger Die Head Design

- Usual Sheet Width:800mm

- Application:Packaging, Stationery, Chemicals, Construction

- Usual Sheet Thickness:0.15mm-2mm

- Extruder Design:Single Screw Extruder

- Transport Package:Wooden Cases with Vacuum Film

- Specification:LMSB

- Trademark:Leader Machinery

- Origin:Qingdao of China

- HS Code:8477209000

- Production Capacity:30 Sets,Year

Description

PAR T1 THIS LINE CONSISTS OF (COMPULSORY)1 Automatic vacuum feeding machine 1 set 2 High efficiency single screw extruder (65/33, 75/33,90/33,120/33) 1 set 3 Hydraulic exchanging unit 1 set 4 T-type /hanger type die head (JC-Times brand) 1 set 5 Three Roller Calendars (alloy steel material ) 1 set 6 Rollers thermoforming machine 1 set 7 Cooling frame and edge cutting unit 1 set 8 Haul off machine 1 set 9 Plastic cutting machine-guillotine 1 set 10 Twin position sheet winder 1 set 11 Stacker 1 set 12 Electrical cabinet (ABB,Omron, RKC, Siemens etc) 13 Spare parts 1 set PART 2 ACCESSORY MACHINE PARTS (OPTIONAL) 1 Air compressor 1 set 2 Industrial water chiller 1 set PART 3 SHEET SPECIFICATIONS 1 Sheet width 600-1200mm 2 Sheet thickness 0.2-2mm 3 Type single layer/multi layer sheets 4 Raw material 1. Can be virgin material

2. Can be recyclable material PART 4 SHEET APPLICATIONS 1 Packing, printing, stationery, art works etc. 2 Main Products: Gift/ad/file bag/lamp cover/food packaging PART 5 PAYMENT, DELIVERY AND AFTER SALE SERVICES 1 Payment terms 40% for prepayment by T/T, 60% for balanced payment by T/T, or L/C can be acceptable 2 Delivery time 70 days after receipt of prepayment 3 Packing method Wooden cases/pallets with stretching films 4 Guaranteed time 18 months for mechanical parts, 12 months for electrical parts 5 After sale service Send 1-2 engineers to customers' factory to help them install, test the machine, and train their workers. This is chargeable 6 Contact Ms Lilly Zhou (mob : 0086-15266238607)

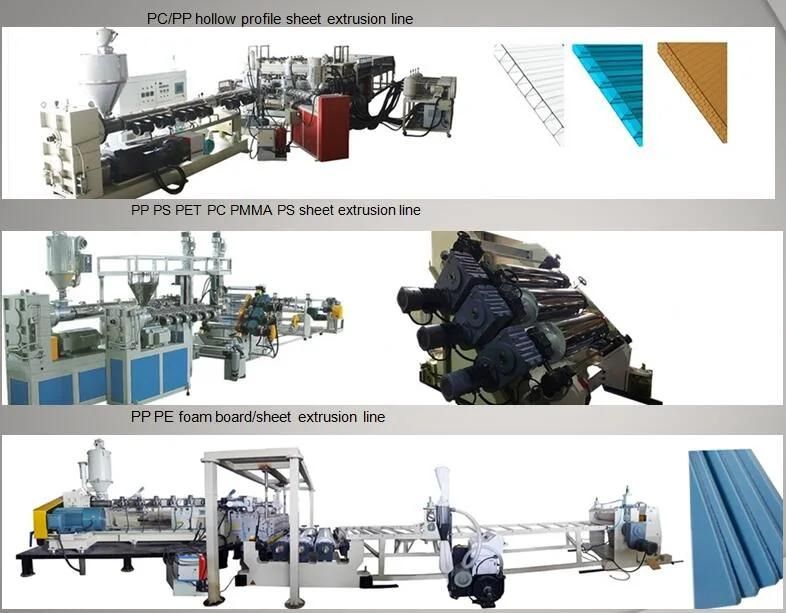

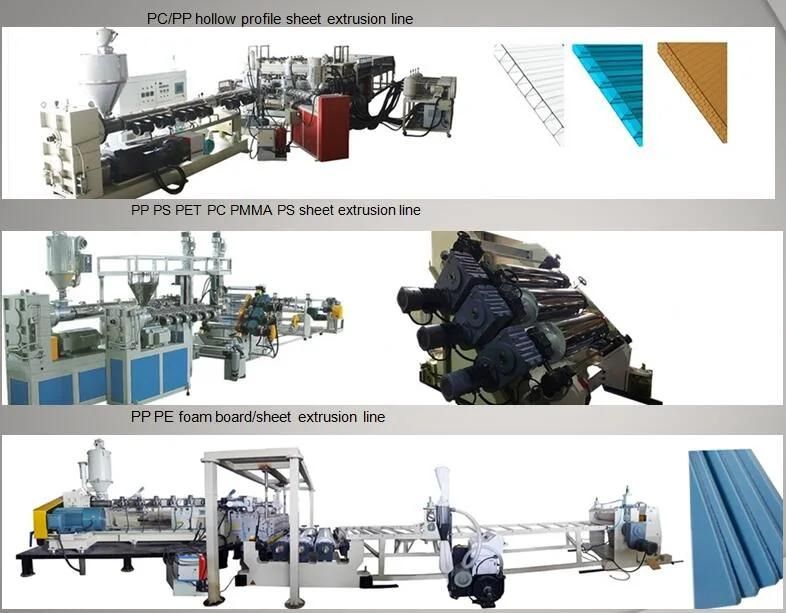

PART 5 COMPANY INFORMATION AND MAIN PRODUCTS:

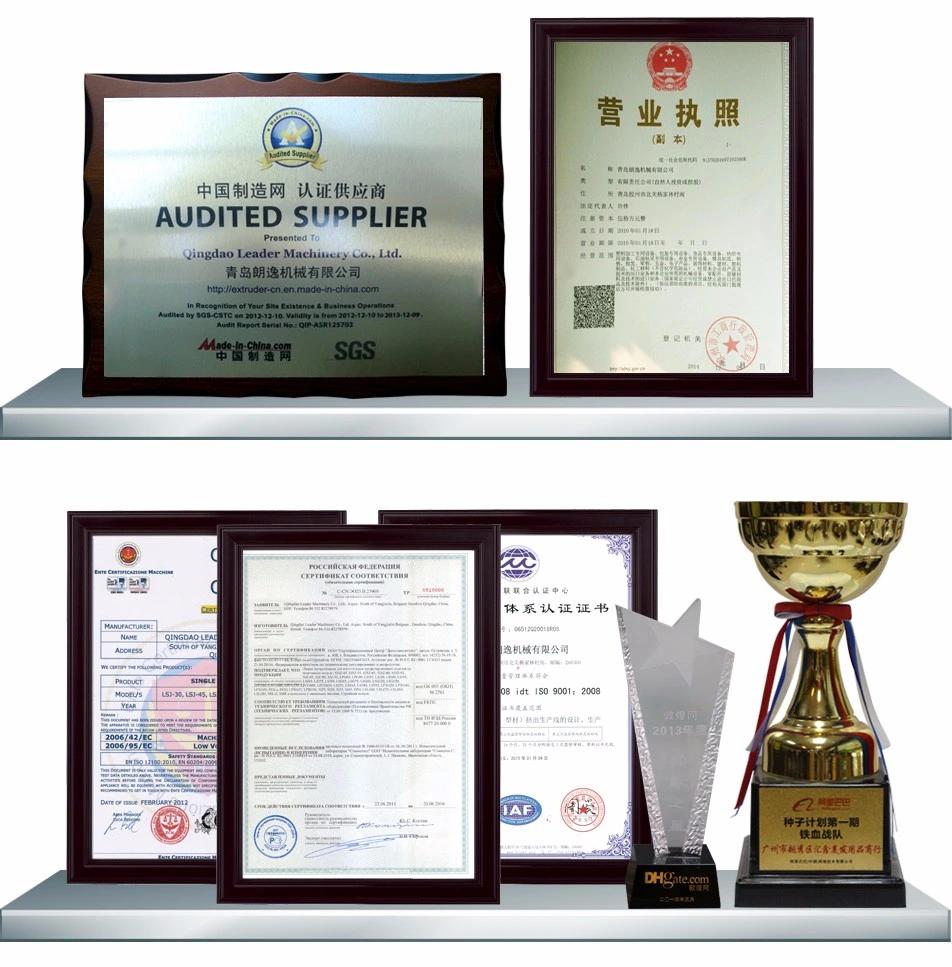

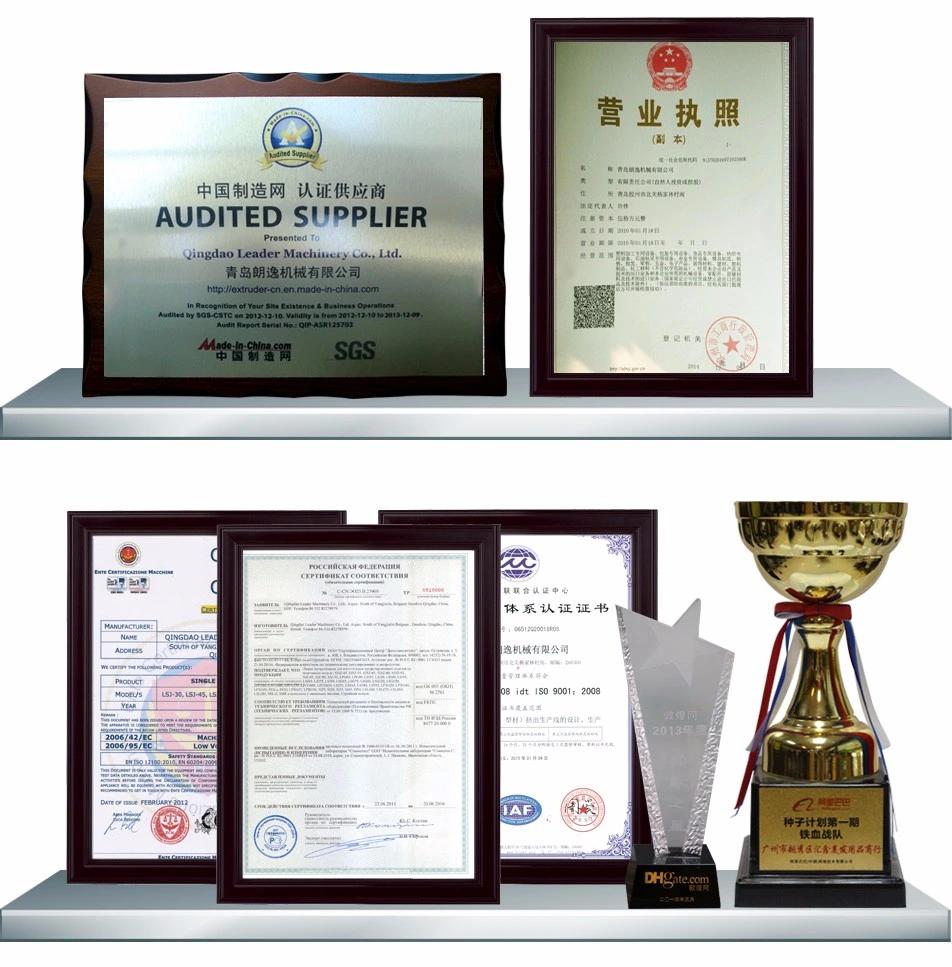

PART 6 COMPANY CERTIFICATIONS:

PART 7 MACHINE PACKING AND DELIVERY

All the machine parts will be packed in wooden cases or pellets with stretching films on machine body.

PART 8 COMPANY OVERSEA SHOWS AND CONTACT DETAILS:

2. Can be recyclable material

PART 5 COMPANY INFORMATION AND MAIN PRODUCTS:

PART 6 COMPANY CERTIFICATIONS:

PART 7 MACHINE PACKING AND DELIVERY

All the machine parts will be packed in wooden cases or pellets with stretching films on machine body.

PART 8 COMPANY OVERSEA SHOWS AND CONTACT DETAILS: