Two-Diehead ABA Co-Extrusion Film Blowing Machine

HEBEI CHENGHENG PLASTIC MACHINERY TECHNOLOGY CO., LTD.- Type:PE Film Blowing Machine

- Raw Material:LDPE,LLDPE,HDPE

- Maximum Folding Width of Film:1000mm

- Screw Diameter:55,50, 30,1; 65,55, 30,1

- Automation:Automatic

- Computerized:Computerized

Base Info

- Model NO.:CHSJ-MH2

- Machine Weight:3800kg; 4200kg

- Certification:CE

- Film Width:200-600mm;250-800mm

- Film Width for Flat Bag:200-600mm; 250-800mm;

- Film Thickness:0.006-0.15mm

- Max Output:125kg,H ; 150kg,H

- Screw Dia:55,50, 30,1; 65,55, 30,1

- Transport Package:Film Wrap , MDF Frame

- Specification:6.5*2.7*5m; 6.5*3*5.8m

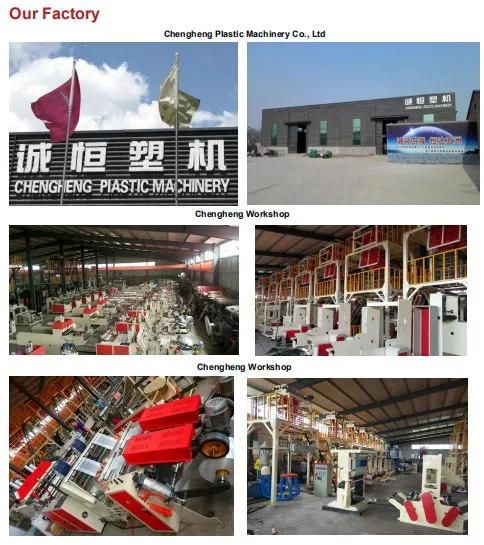

- Trademark:Chengheng

- Origin:China

- HS Code:8477309000

- Production Capacity:100 Sets Per Year

Description

Basic Info.

Model NO. CHSJ-MH2 Machine Weight 3800kg; 4200kg Certification CE Film Width 200-600mm;250-800mm Film Width for Flat Bag 200-600mm; 250-800mm; Film Thickness 0.006-0.15mm Max Output 125kg/H ; 150kg/H Screw Dia 55/50, 30/1; 65/55, 30/1 Transport Package Film Wrap / MDF Frame Specification 6.5*2.7*5m; 6.5*3*5.8m Trademark Chengheng Origin China HS Code 8477309000 Production Capacity 100 Sets Per YearProduct Description

CHSJ-MH2 Double Heads ABA Blown Film Co-Extrusion Machine

| Model | MH2-ABA-55-50/700 MH2-ABA-65-55/900 |

| Film width (mm) | 200-600mm 250-800mm |

| Film thickness | 0.006-0.15mm |

| max output | 125kg/h 150kg/h Depends on different width,thickness of film, die size and raw material characteristics |

| Raw material | HDPE/LDPE/LLDPE |

| Diameter of screw | Φ55/50,30/1 Φ65/55,30/1, SACM 645 ,bimetallic .five years guarantee |

| Main motor | 22kw/18.5kw 30kw/22kw 100% Original three-phase variable frequency motor Equipped with inverter control |

| Take up roller(mm) | 700mm 900mm |

| Weight | 3800kg 4200kg |

| Machine size | 6.5*2.7*5 6.5*3*5.8 |

Our service:

1.Guarantee period: 5 year Garantee for Screw, from the date customers receive the machine.

lifetime warranty for after-sales service and mechanical parts.

2.Delivery:within 35-40days finish production,we start to manufacture the machine after we receiving 30% of the payment as deposit.

3.Packing: Film Wrap

4. After sale service:

We can arrange engineer to install the machine and training worker, but customers need to pay the charges, including flight tickets cost, accomodation cost, salary USD/day.

Free installation, ajustment and training for consumers purchase more than $100000 only

5.Professional advices and consultancy for the relating machines in 24 hours.

Our products

- Blown film extrusion machine, co-extrusion blown film machine. For 1-5 layers blown film made of LDPE, LLDPE, HDPE, OPP, PP, (bio) degradable plastics, recycled material and blends.

- Bag making machine. For flat bags, Vest(T-shirt) bags, string drawing bags, Garbage bags, carry bags, roll bags, (Courier)permanent adhesive bags, laminated bags.

- Plastic film printing machine. Plastic Laminating machine.

Our Blown Film Extrusion Machine

Our AUtomatic Bag making Machine

We have gained CE, SGS, or BV certificates for most of our products.

SGS and TUV audited plant. Golden member of Made-in-China

The factory is located in Ningjin Plastic industrial zone in North China, out of Shijiazhuang city, hebei province, about 3 hours driving south of Beijing airport.