High Quality PE/HDPE Pipe Production Extrusion Line

Qingdao Xindacheng Plastic Machinery Co., Ltd.- Product Type:PE Pipe

- Screw No.:Single-screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008

- Customized:Customized

Base Info

- Model NO.:XDC- HDPE Pipe Extrusion Line

- Condition:New

- Name:HDPE Pipe Extrusion Line

- Electric:Siemens

- Raw Material:HDPE

- Diameter:16mm-1200mm

- Screw Material:38crmoaia

- Screw L/D Ratio:33

- Color:Customizable

- Delivery Time:60-90days

- Gurantee:1 Year

- Transport Package:Sea Package

- Specification:CE, ISO9000-2001

- Trademark:xindacheng

- Origin:China

- HS Code:84778000

- Production Capacity:30set,Year

Description

Product Parameters

Product Description

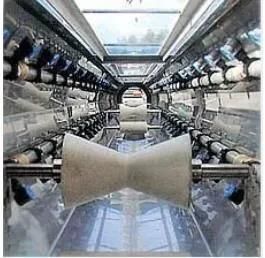

The tube sizing:

1. The sizing sleeve with the entrance water curtain is applicable to the HDPE,LDPE and PP etc.2. There is a closed inside room on the front end of butterfly type sizing sleeve, and it is applicable to the small tube extrusion specially.

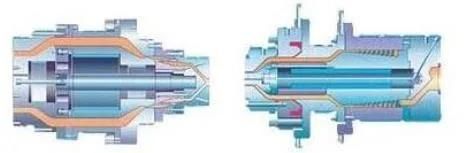

HDPE Pipe Production Line The mould:

1. Standard series: 10-1600mm spiral allotment type or skep types flow divide body.

2. The best design of low melting temperature causing small tube internal stress and smooth inside and outward appearance.

3. High flexibility is applicable to all polyolefin material multi-layer co-extrusion form.

The vacuum sizing water tank:

1. The water pump of high power and spraying head of special design bring high efficient spraying cooling.

2. On the section of sizing sleeve establish dense and intensive spraying heads.

3. The percolation unit with the bypass pipeline improved the stability of the equipments and reduce maintenance.

4. Have the high and low water level control levels.

5. Three-dimensional adjusting.

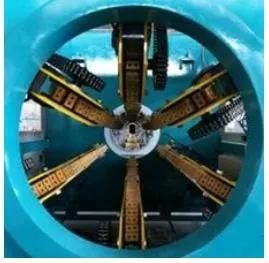

Tractor machine:

1. Changing frequency speed adjusting system guarantee synchronous hauling off.

2. With the proportion valve and gas pressure control to regulate precisely

3. With the central motor drives all bedrails to attain highly synchronous result.

4. The automatic tube wall thickness increases and the length measuring device may be chosen.

The sawing machine

1. Blade type machine.

2. The planet type incising machine.

3. The circle cut type incising machine.

4. The function for setting automatic cutting.

5. Low noise and high protection design

6. Vivid and dependable roller type voves.

HDPE Pipe Production Line The extruder:

1. PLC or temperature gauge control.

2. HIgh extrusion capacity, low melt temperature.

3. Special screw design insure the high-efficiency and high yield.

4. Bevel gear design of high hardness and low noise brings dependable performance and long service life.

5. Adoption direct current speed regulation, the frequency variable speed adjusting and the electromagnetism speed.

Company Profile

Exhibition

Our Client

Certifications

Packaging & Shipping

FAQ:

Q: Where is your factory? How can I get there?

Way 1: you take the train to Gaomi station (Weifang City), we will pick you up. It's only 30 minutes from our factory to Gaomi station.

Mode 2: take a plane to Liuting International Airport (Qingdao), we will meet you, 40 minutes from the factory to the airport.

Q: how is your factory doing in quality control?

A: the electrical part has cooperated with famous foreign brands such as Yaskawa, Siemens, NSK, Delta, Panasonic, etc. the other part comes from domestic high-quality manufacturers and will be tested before delivery.

Q: is there any overseas service?

A: Yes, we have an experienced service team. Each team member has gone abroad many times and has rich experience in machine installation. But the buyer needs to provide air tickets, food, hotel fees, etc.

Q: how does your company provide after-sales service?

A: all machines purchased from our company are provided with a one-year warranty period (except for human errors). We will supply some spare parts for replacement at the time of delivery. In case of damage to machine parts in the warehouse, we will send you free parts by express as soon as possible.