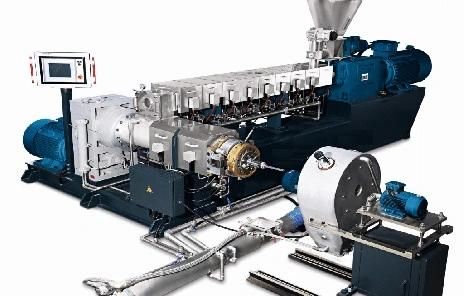

Plastic Extrusion Machinery Pelletizing Line Twin Screw Extruder for Compounding

Polytek (Nanjing) Intelligent Equipment Co., Ltd.- After-sales Service:24 Hours on Call

- Warranty:12 Months

- Type:Twin Screw Extruder for Compouding

- Plastic Processed:PP PE Pet PC ABS TPR TPE TPU TPV PVC

- Product Type:Granulating Extruder

- Feeding Mode:Multiple Feed

Base Info

- Model NO.:PTH

- Assembly Structure:Separate Type Extruder

- Screw:Twin-Screw

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Processing Product:Engineering Plastic, Masterbatch, High Filler etc.

- Certification:CE ISO9001 SGS

- Keyword:Twin Screw Extruder

- Screw Diameter:22mm,25mm,36mm,51mm,62mm,71mm,94mm

- Model:Pth-20,25,35,50,65,75,95

- Power:5.5kw,22kw,75kw,200kw,355kw,550kw,710kw

- Capacity:High Torque Machine up to 4000kg,H

- Application:Compound.Cutting.Pelletizing.Granulating

- Extrusion:Parallel Twin Screw Extruder

- Transport Package:Wooden Case for Sea Transportation

- Trademark:Polytek

- Origin:Nanjing, China

- HS Code:84772090

- Production Capacity:Over 100 Lines Per Year

Description

Construction :

Application for Plastic Double screw extruder/Twin Screw Extruder air-cooling pelletizing

1. PP/PE/ABS+Caco3/Sio2 (silicon dioxide)/talc (chalk)/carbon blac;

2. Degradable masterbatch:

PE/PS+starch/ poly lactic acid (PLA)/soy Starch;

3. Anti-flame (flame retardant) masterbatch:

PP/ABS/PS/EVA/PA+Mg(OH)2 (magnesium hydroxide)/Al(OH)3 (aluminum hydroxide);

4. Cable material:

PVC cable, PVC transparent bottle material;

5. Wood plastic:

PP/PE/PVC+wood powder (wood flour)/bamboo powder(bamboo flour)/fiber (filament, staple)

Spare parts and service, we are not only selling machine, but also our knowledge and service

Owe to rich theoretical knowledge and experience in compounding fifield, we can offer best solution to meet customer's requirement, not only for local extruders. We can also provide standard parts of Coperion, Berstoff, JSW, Toshibar, Steer etc.

About Polytek

Purchasing from POLYTEK is only the beginning of our relationship. We are committed to the success of our customers and we support

you and your equipment throughout the life of your investment. We provide expertise with preventative maintenance plans, health and

wellness checks, and training services so that you can focus on what you do best: sell your product.