Plastic PVC|HDPE|PE|PP|PPR|CPVC/LDPE Electricity Conduit Tube/ Water Sewage Pipe/ Door ...

Zhangjiagang Kangju Machinery Co., Ltd.- After-sales Service:Supply

- Warranty:Two Years

- Type:Pipe Extruder

- Plastic Processed:PE

- Product Type:Granulating Extruder

- Feeding Mode:Multiple Feed

Base Info

- Model NO.:SJ50-38

- Assembly Structure:Integral Type Extruder

- Screw:Single-Screw

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Transport Package:by Ship with Wood Box Packed

- Specification:3600*1500*2600

- Origin:China

- HS Code:8477800000

- Production Capacity:100 Lines Per Year

Description

Basic Info.

Model NO. SJ50-38 Assembly Structure Integral Type Extruder Screw Single-Screw Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Transport Package by Ship with Wood Box Packed Specification 3600*1500*2600 Origin China HS Code 8477800000 Production Capacity 100 Lines Per YearProduct Description

PE PP Pipe Extrude Machine lineThis pipe production line is mainly used for producing large diameter HDPE/LDPE/PE pipe. The pipe has some excellent features such as heating resistant, aging resistant, high mechanical strength, environmental stress cracks resistant, good creep resistant, etc. It is a preferred gas conduit for ductwork systems between city and its suburb, water supply in city.

Features:

High efficiency extruder is designed for HDPE pipe, equipped with reducer which is high speed and low noise, feeding section with cooling unit and reversing spiral groove, different pitch undulant screw which allows great output, lower melting temperature, and lower energy consumption.

Constituent of plastic making machine:

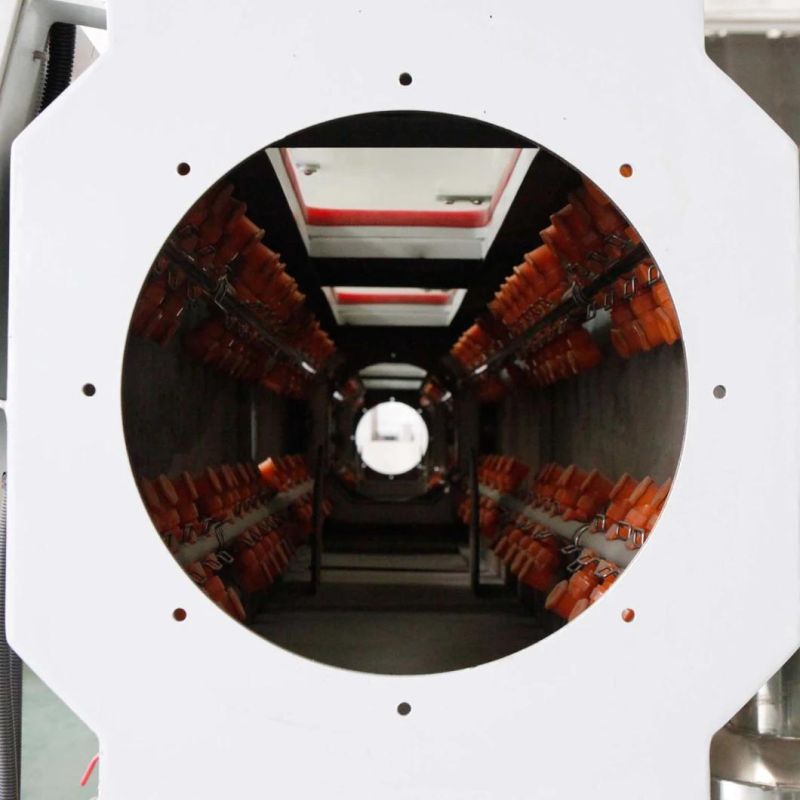

1. Distributed spiral composite extrusion die-head ensures the melting pressure and flux even and stable, the surface of pipe smooth and glossy;

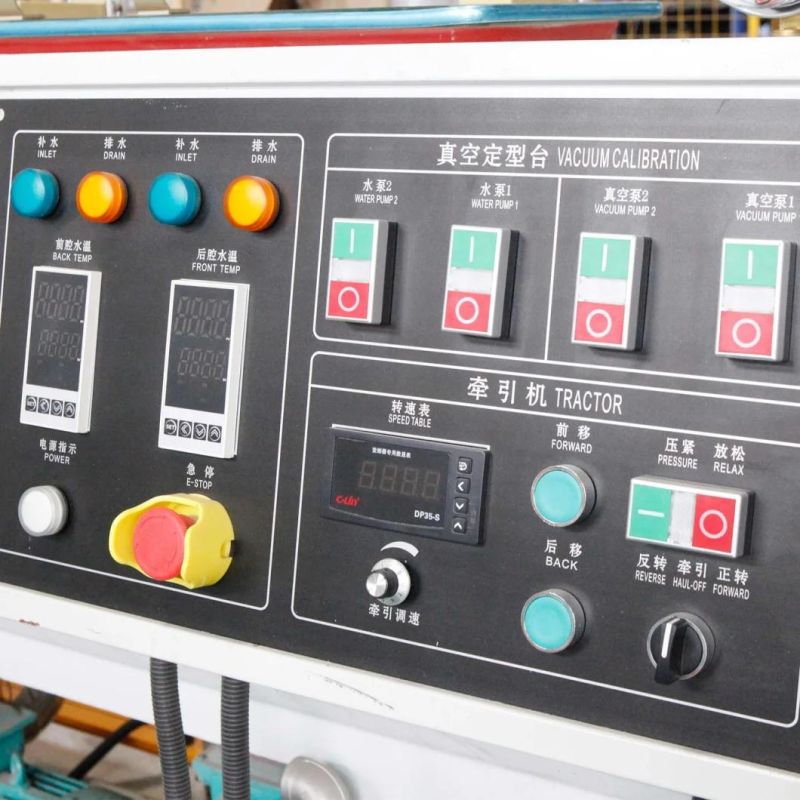

2. Vacuum calibration and spray water cooling tank made of stainless steel ensures precise calibration and fast cooling;

3. Adopts multi claws haul-off unit, speed adjusted by frequency inverter;

4. Equipped with planetary cutter. Be able to cut large diameter and thick wall pipe;

5. Equipped with pipe-making line;

6. Small diameter use winding machine. Large dimaeter pipe used stacker.

Main technical parameters:

| Extruder model | Pipe diameter | Extruder | Output | Power | Extruder Power |

| SJ45 | 16~32mm | SJ45/30 SJ25/25 | 30~60kg/h | 40kw | 22kw |

| SJ65 | 20~75mm | SJ65/33 SJ25/25 | 80~120kg/h | 65kw | 37kw |

| SJ75 | 50~160mm | SJ75/33 SJ25/25 | 80~150kg/h | 150kw | 75kw |

| SJ90 | 75~250mm | SJ90/33 SJ25/25 | 280~350kg/h | 200kw | 110kw |

| SJ120 | 160~315mm | SJ120/33 SJ30/25 | 300~450kg/h | 280kw | 185kw |

| SJ150 | 315~630mm | SJ150/33 SJ30/25 | 550~800kg/h | 420kw | 285kw |