Car Seat Product Foaming Line

Zhangjiagang Strength & Industrious Machinery Co., Ltd.- Type:Polyurethane Foam Machine

- Raw Material:PU

- Principle:High-Pressure Air Type

- Automation:Automatic

- Computerized:Computerized

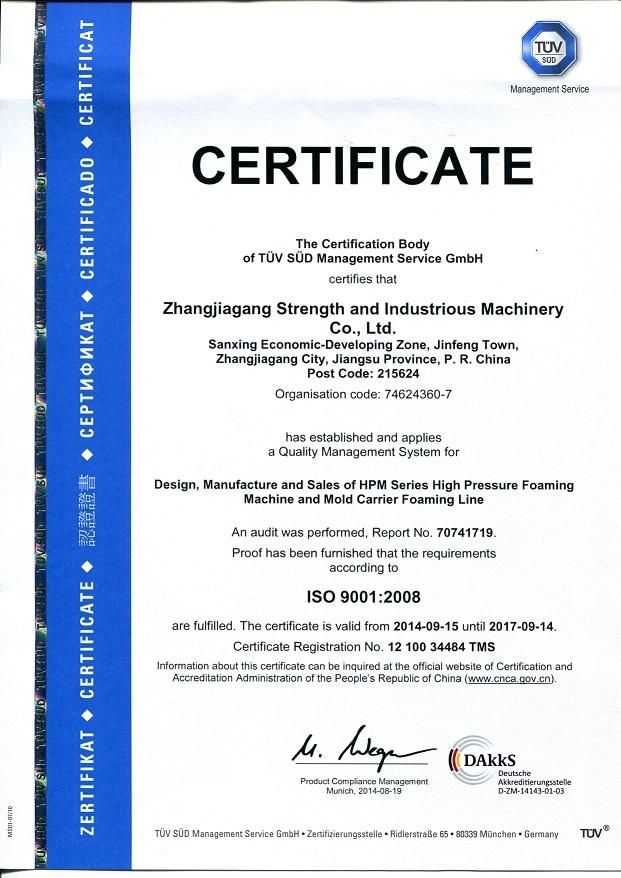

- Certification:CE, ISO9001:2008

Base Info

- Model NO.:RT13600,18

- Model No:Rt13600,18

- Type;:Polyurethane Foam Machine

- Raw Material;:Polyol and Isocyanate

- Principle;:High Pressure Impact

- Automation;:Automatic

- Computerized;:Computerized:

- Certification;:Ce, ISO9001:2008

- Voltage:380V or Other Power Customizable

- Power:40kw-100kw

- Warranty:12 Months

- Transport Package:Wood

- Trademark:ZSIM

- Origin:Zhangjiagang

- HS Code:8477800000

Description

Basic Info.

Model NO. RT13600/18 Model No Rt13600/18 Type; Polyurethane Foam Machine Raw Material; Polyol and Isocyanate Principle; High Pressure Impact Automation; Automatic Computerized; Computerized: Certification; Ce, ISO9001:2008 Voltage 380V or Other Power Customizable Power 40kw-100kw Warranty 12 Months Transport Package Wood Trademark ZSIM Origin Zhangjiagang HS Code 8477800000Product Description

HPM series high-pressure foaming machine is zhangjiagang strength and industrious Machinery Co. Ltd following the international latest high technology and according to word wide the PU industry that independent innovation high technology products .The main parts are import from foreign country, equipment technical and safely performance are reached the word wide advanced capacity. The equipment is widely used automobile industry, insulation industry, air conditioning industry, electric appliance industry and furniture industry and so on. Also, expanding the application field .

HPM high -pressure foaming principle

Both Polyol and Isocyanate are stored separately in two tank, and used two rotary axial metering pumps to take material to mixing head, two components injection to a small mixing room at high pressure and flow rate when mixing head started in the hydraulic control, and collide with each other instantly, pass moving transformation that reached to mixing and flow to mold control, after pouring output time that mixing head piston rod forward, all material are pushed to mixing chamber and mixing chamber is cleaned by piston rod, don't left any material. Component passed beside of piston rod return to material tank. If it don't inject in a long time , low-pressure recalculation switchover unit but two-control component into low recalculation.

Because of equipment' exact calculation, has a small loss and needn't clean and it will be good at environment-protect and reduce the material costs. In the all areas that is to be more and more widely used.

The line is including 1 set HPM high pressure foaming machine, 1 set Turntable, mold carriers, Mold temperature control system.

The production line using automated batch or continuous operation, automatic opening / closing the mold, the robot operating mixing head casting production mode, each part of the device is equipped with advanced electric control system, adjustable separately (idling), run online production.