PE/PP/ABS/PVC/HDPE/PMMA/PC Thick Sheet/Plate/Board Extrusion/Extruding Production Machine ...

Qingdao Sincere Machinery Co., Ltd.- After-sales Service:Sincere Provide Installation and Debug Service

- Warranty:1year

- Product Type:Plastic PE,PP,ABS,PVC,PMMA,PC,Pet Sheet,Plate,Boar

- Board Layers:Single Plate

- Screw No.:Single-screw

- Automation:Automatic

Base Info

- Model NO.:SJ90, SJ120, SJ150, SJ180

- Computerized:Computerized

- Certification:CE, ISO9001:2008, TUV

- Customized:Customized

- Condition:New, Under The Order

- Sheet Types:Sheet Surface Matte or Smooth,Vacuum Forming Sheet

- Delivery Conditions:Fob CIF CIP

- Processing Period:60 Working Days

- Line Diamision:20m*3*3m

- Line Weight:14t-30t

- Sheeting Machine Output:150kg-900kg,H

- HDPE Plate Structures:Single Layer or Multi-Layer,a,Ab,ABA,ABC

- Three-Roll Calender:Mirror,Embossed,Dimpled ,T-Grip,K-Type Roller

- Plastic Sheet Extrusion Mould:T-Die Head, Sheet Extrusion T-Die Mould

- Plastic Plate/Board Advantages:Cleanable, Recyclable, Environmental,Anticorrosive

- Plastic Sheet Extruder Models:Sj90, Sj120, Sj150, Sj160, Sj170, Sj180

- Three-Roller Temperature Control Method:Thermostat or Water Chiller

- Plastic Sheet Machine Optional Device 1:Gravimetric Four-Component Mixing System

- Plastic Sheet Machine Optional Device 2:Palstic Sheet,Board,Plate Crushers and Pelletizer

- Plastic Sheet Machine Optional Device 3:Plate Butt Welding Machine and Plate CNC Router

- Transport Package:Stretch Film and Wooden Pallet, Wooden Packing

- Specification:sheet width 600, 900, 1200, 1500, 1800, 2000mm

- Trademark:Sincere Machinery

- Origin:Qingdao, China

- HS Code:8477209000

- Production Capacity:50 Sets Year

Description

PP/PE/ PS/PC/PMMA/PET/PETG/TPU/ABS/EVA/EVOH Sheets Line Consists:

PP PE HDPE ABS PVC Thick sheets production line Consists:

1.

Single Screw Extruder or Double screw extruder

1 set or 2 sets or 3 sets

2.

Duplex hydraulic screen changer for Single Screw Extruder line

1 set

3.

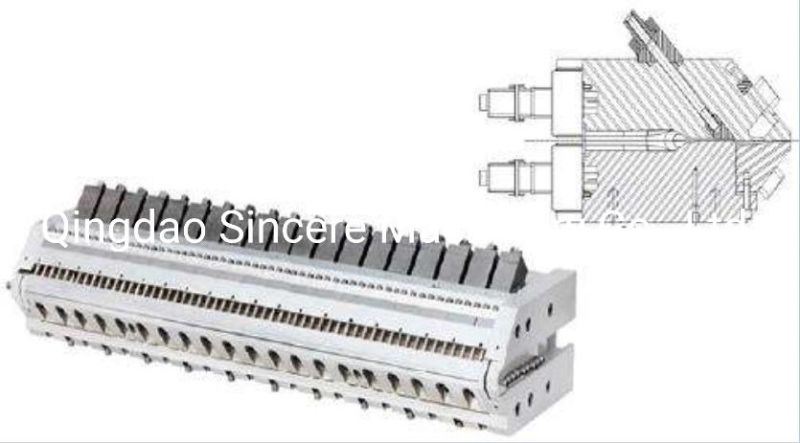

Extrusion Die Head T-die Head

1 set

4

Three Roller Calendar

1 set

5

Cooling Frame

1 set

6

Edge Trimming Unit

1 set

7

Edge Material Crushing Unit

1 set

8

Double Roller Hauling off Machine

1 set

9

Cutting off Machine or Double Station Winding Machine

1 set

3.Technical Parameters.

PP/PE/PS/PC/PMMA/PET/PETG/TPU/ABS/EVA/EVOH

Extruder

Extruder Appropriate single-screw extruder (exhaust or not) or Parallel twin screws extruder, should be chosen on the basis of different materials. Specially designed screw and advanced temperature controlling system ensure the good plasticization, high output and stable extruding.Screen changer:The quick screen changer of hydraulic system ensures the short course of screen changing without material-leakage.

Extrusion T-die head mould:

Extrusion T-die head mould:Reasonable structure of mould should be chosen in terms of material, whereas moulds of clothes-rack mode are widely accepted to regulate flow-distribution and guarantee even thickness of plates (sheets).

Three-roller calendaring machine:

Inclined and vertical three-roller calendaring machine should be chosen according to the thickness of the plates(sheets). Temperature controller operates separately and gap among the three rollers can be adjusted freely, and the central roller has special design of regulating angle. Both ensure the excellent calendaring effect and even thickness of plates (sheets).Bracket of cooling roller:Equipped with corresponding guide roller, the cooling effect is better. In addition, the edge-shearing device equipped can guarantee fixed width of plates (sheets) and quality of edge.

Edge side cutting device online, so the side of sheet will be smooth and uniform, the cutting wastage can be reused for production

Cutting side online crushing and recycling device, it can make the cutting wastage into small flakes.

Haul-Off Device.

Landscape orientation cutting machine:

It is of length-fixed cutting with cutting precision less than 2mm and adopts alloy blade or rigid alloy saw bit to ensure the good cutting effect and constantly stable performance.

Raw material drying device, color mixing device, plastic shredder.

4. Extrusion Line Characteristic:

- Adopting the oversea advanced technology to make the optimization design with big screw L/D ratio and high production capacity.

- To change the net by full-auto hydraulic changing net, easy and fast.

- The upper and lower roll wheel of 3-roll calendar are adopted the hydraulic moving, the pressure can be adjusted, suitable for the different materials.

- Adopting double station center winding for the winding device, matched the magnetic powder tension control.

Ekaterina

8615726275773