High Speed Film Lamination PVC Wall Panel Equipment

Qingdao Sunshine Machinery Co., Ltd.- After-sales Service:12 Months

- Warranty:12 Months

- Product Type:PVC Board

- Board Layers:Single Plate

- Screw No.:Double-screw

- Automation:Automatic

Base Info

- Model NO.:SJSZ65

- Computerized:Computerized

- Certification:CE, ISO9001:2008

- Customized:Customized

- Condition:New

- Name:PVC Wall Panel Equipment

- Motor Power:22kw, 37kw

- Inverter:Taida, ABB

- Low Voltage Units:Siemens

- Capacity:100-400kg,H

- Transport Package:Wrapping with Plastic Film and Fix Into Container

- Specification:SJSZ51,105, 65,132

- Trademark:Qingdao Sunshine Machinery

- Origin:Qingdao, China

- HS Code:84772090

- Production Capacity:100-400kg,H

Description

Basic Info.

Model NO. SJSZ65 Computerized Computerized Certification CE, ISO9001:2008 Customized Customized Condition New Name PVC Wall Panel Equipment Motor Power 22kw, 37kw Inverter Taida, ABB Low Voltage Units Siemens Capacity 100-400kg/H Transport Package Wrapping with Plastic Film and Fix Into Container Specification SJSZ51/105, 65/132 Trademark Qingdao Sunshine Machinery Origin Qingdao, China HS Code 84772090 Production Capacity 100-400kg/HProduct Description

High speed film lamination PVC wall panel equipment Brief introduction of high speed film lamination PVC wall panel equipment

Brief introduction of high speed film lamination PVC wall panel equipmentPVC wall panel equipment is one of featured products made by our Qingdao Sunshine Machinery Co., Ltd, which features in high speed, stable production line, fully automation etc. The motor and electricity units can be international famous brand or our Chinse famous brand according to our different customer's choice.

The finished product PVC wall panel around the market, width 300mm, 400mm, 600mm etc. height or you called the thickness will be 6, 7, 8, 9mm etc. according to our customers' market demand.

Consist of the PVC wall panel equipment

1) Mixer- mix the needed material, such as PVC resin power, calcium carbonate powder plus other chemical additives together.

2) Extrusion line

2.1 Conical twin screw extruder (according to different customers' choice, it can be 51 55 or 65 conical twin screw extruder, we can advice you according to the finished PVC wall structure and specifications.

The conical twin screw extruder mainly includes conical twin screw and barrel, the motor, reduction box, heating rings, hopper, electrical control cabinet (low voltage electric units can be Simens etc. Inverter we mainly equip with our customers the Taida or ABB brand)

With die head and mold according to different customer's detail finished product size.

2.2 Vacuum calibration table

4m, 5m, 6m can be customized, its main function is to cool the finished PVC wall panel, let the extruded PVC ceiling with 170 degree by the vacuum calibration table to cool natural forming needed.

2.3 Hauling machine

The hauling machine pulls the PVC wall panel go forward, with excellent quality plain rubber block.

2.3 Online lamination machine

The main function of the lamination machine is to let the PVC wall panel surface laminate a different style and flower color, which satisfy different customers' needed style and colors.

The main function of the lamination machine is to let the PVC wall panel surface laminate a different style and flower color, which satisfy different customers' needed style and colors. 2.4 Cutting machine

The cutting machine can make the PVC ceiling as customers' length demand. Such as 6m, 4m etc.

2.5 Stacker or Auto stacker can be chosen

The auto stacker save a lot of time and man power to reive the finished length PVC ceiling.

If auxiliary machine is also in your plan, such as crusher, and power miller, we also can help you equip.

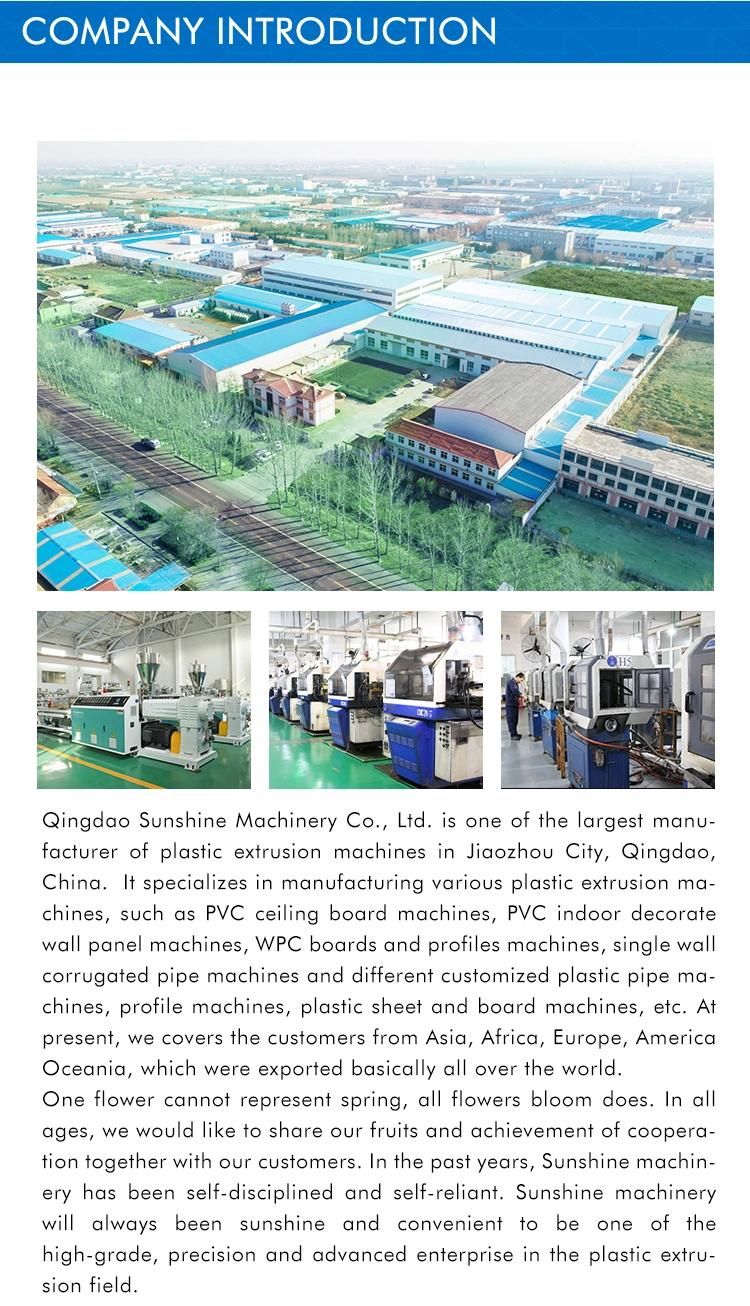

About us

Our partners

Our customers

Sincerely welcome to contact us by made in China if you are interested in our PVC wall panel equipment!

Sincerely welcome to contact us by made in China if you are interested in our PVC wall panel equipment!