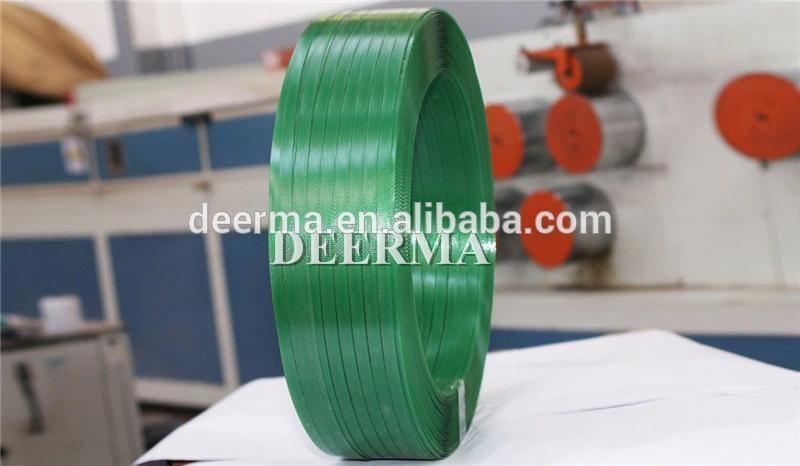

Pet Strap Band Production Line Pet Strap Band Machine

QINGDAO DING KUN PLASTIC MACHINERY CO., LTD.- Plastic Processed:Pet or PP

- Product Type:Pet Strap Machine

Base Info

- Model NO.:SJ75,30

- Feeding Mode:One Feed

- Assembly Structure:Integral Type Extruder

- Screw:Single-Screw

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Name:Pet Strap Machine

- Extruder:Sj75,30 Single Screw Extruder

- Motor:Siemens Brand

- Inverter:ABB

- Temperature Control System:Omron

- Certification:Ce,SGS

- Transport Package:Export Standard

- Specification:CE, SGS,TUV

- Trademark:DEERMA

- Origin:Qingdao

- HS Code:8477209000

- Production Capacity:20 Sets, Year

Description

Machine List

Second haul off machine: Consisted by the second hauling tension, electrical motor and

the traction roller, etc

the traction roller, etc

is automatic .And it is consisted by the coiling roller, coiling core and the stander, the

coiling roller is consisted of electrical motor, reducer and the transmission system

Feature 1:

• Raw material process and extrusion system.

• High performance crystallizing and drying system.

• Production can use 100% recycled material to obtain a high add value strapping band.

Feature 2:

• Continuous back-flush screen changer operating technology (Europe technology).

• 100% full automatic self-cleaning screen changer.

• Double column 4 screen cavities.

• PLC Control , change screen without production interrupted , not influence the production quality

Feature 3:

• Special designed hot air stretching oven.

• Configured with heating unit and automatic temperature control system.High performance heat insulating layer.

• Better on strip stretching and heating, rapid heating, complete strip orientation stretching.

Feature 4:

• Heating oven for sizing

• Special designed technology, make sure the strip forming rapidly • Prevent the strip from un-orientation after orientation, eliminate internal stress,make sure the quality of strip accuracy and quality.

Machine Pictures

APPLICATION FOR PET STRAPS

Packaging & Shipping

CERTIFICATION

Service & Warranty

Execellent Service-Turnkey Project

DEERMA is committed to providing full support for its local and international clients and dealers and will always provide a prompt response to customer enquiries.

A. Free training for maintenance personnel;

B. Installation service& commissioning by porfessional;

C.The establishment of user fles, a long-term follow-up service and regular return visits;

D. A 24-hour hot-line service ensures the timeliest solution to your faulty equipment.

E.Calling or Door to Door service

F.One year guarantee for whole machine