18 Month Warranty PP Sheet Foam Plate Extrusion Machine

Qingdao Leader Machinery Co., Ltd.- After-sales Service:Available

- Warranty:1.5 Years

- Product Type:PP Board

- Board Layers:Multilayer

- Screw No.:Single-screw

- Automation:Automatic

Base Info

- Model NO.:LSJ-120,34

- Computerized:Computerized

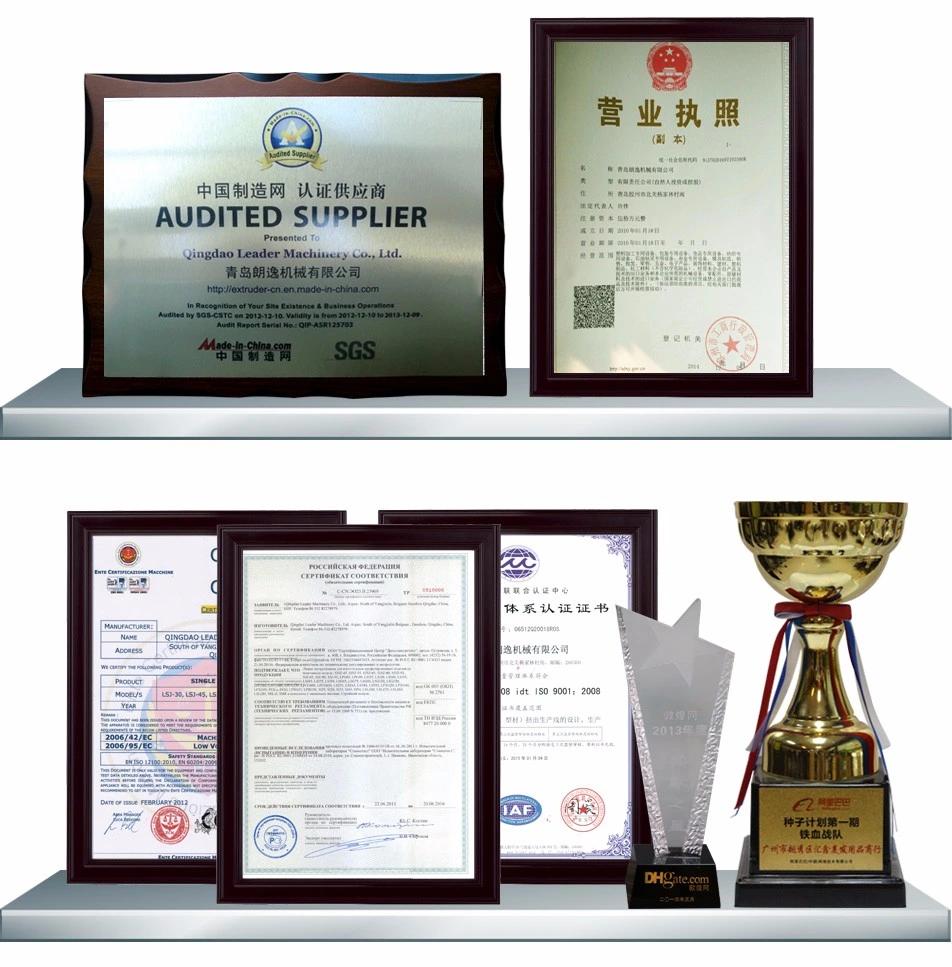

- Certification:CE, ISO9001:2008

- Customized:Customized

- Condition:New

- Name:PP Foam Sheet Extrusion Machine

- Extruder Model:Sj-120,34 Single Screw Extruder

- Extrusion Capacity:300kg,H

- Installed Power:320kw

- Sheet Width:800-1260mm

- Sheet Thickness:1-6mm

- Die Head:T-Type Die Head-Jc-Times Brand

- Calibrating Method:Three Roller Calendars

- Guaranteed Time:18 Months

- Transport Package:Wooden Cases and Wooden Pallet

- Specification:PP sheet extrusion line

- Trademark:Leader Machinery

- Origin:Qingdao China

- HS Code:8477209000

- Production Capacity:35 Sets Per Year

Description

PART 3: main featurees of our PP sheet making machine:

1.Special designed high plasticization high efficiency screw, head finishing reduction gearboxes and high quality converter motors make high output capacity extruder;

2.Well known brand electrical components, high torque force motors, advanced energy saving design lowered energy consumption mostly;

3.High precise T-type die-head, independent oil temperature control high accuracy 3-roller calender, uniform speed and high

traction force haul-off machine with clamp force adjustable rollers make uniform thickness sheet plate production;

4.Whole line with high degree of automation, saving labour resources;

5.Advanced design concept, high quality steel material used in line, strict producing process make high quality lines and can using longer.

PART4 CONTACT INFORMATION:

Name: Ms Lilly Zhou

PART 6 COMPANY INFORMATION AND MAIN PRODUCTS:

PART 7 COMPANY CERTIFICATIONS:

PART 8 MACHINE PACKING AND DELIVERY

All the machine parts will be packed in wooden cases or pellets with stretching films on machine body.

PART 9 COMPANY OVERSEA SHOWS

PART 9 OUR COOPERATED SUPPLIERS LIST

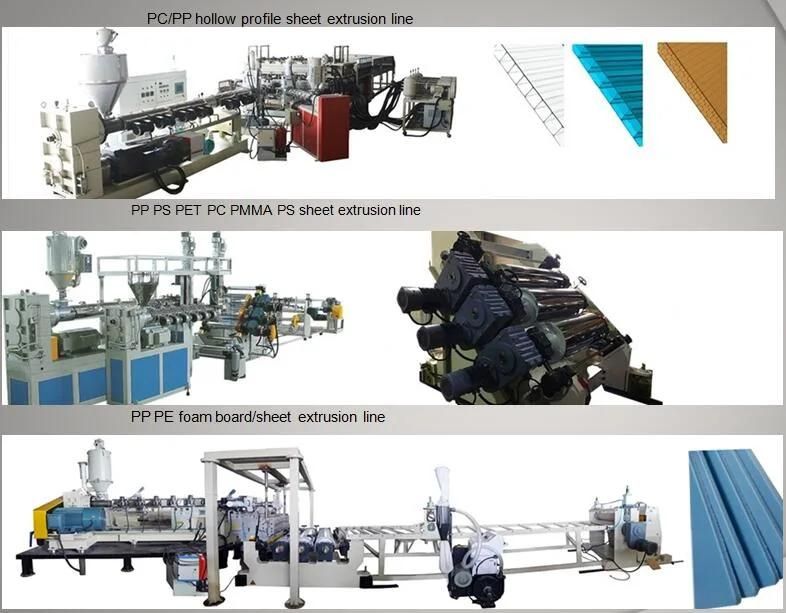

PART 11 OTHER KINDS OF PLASTIC SHEETS/PLATES EXTRUSION LINE RECOMMENDATION :

1. PET sheet extrusion machine:

Processing material: PET virgin pellets(APET or PETG) plus flakes; Or 100% flakes

Thicknes range: 0.2-1.5mm

Net sheet width: 650mm-1500mm(or as per cusotmer's requirement)

Layer structure: Signle layer or multi-layer

Capacity: 150-650kg/h

Application: Thermoforming(cup, bowel, etc. ), stationery, printing sheet, packaging, etc.

2. PP/PS sheet extrusion machine:

Processing material: PP/PS virgin pellets plus recycle material;

Thickness range: 0.15-2mm

Net sheet width: 650mm-720mm-1000mm-1300mm-1500mm(or as per customer's requirement)

Layer structure: Single layer or multi-layer

Capacity: 200kg/h-1000kg/h

Application: Thermoforming(cup, bowel, etc. ), stationery, printing sheet, packaging, etc.

3. ABS/HIPS sheet extrusion machine:

Processong material: ABS/HIPS virgin pellets plus recycle material

Thickness range: 1-6mm

Net Sheet width: 1200mm-1600mm-2100mm(or as per customer's requirement)

Layer Structure: Single layer or multi-layer

Capacity: 300-800kg/h

Application: Vacuum forming, thermoforming, refrigerator inner layer, suitcase, etc.

4. ABS/PMMA sheet extrusion machine:

Processing material: ABS/PMMA virgin pellets plus recycle material

Thickness range: 1-8mm

Net sheet width: 1200mm-1600mm-2100mm(or as per customer's requirement)

Layer structure: Single layer or multi-layer

Capacity:300-800kg/h

Application: Vacuum forming, bathtube, etc.

5. PE sheet extrusion machine:

Processing material: HDPE/LDPE/LLDPE virgin pellets plus recycle material

Thickness range: 1-2.5mm, 3-35mm

Net sheet width: 1200mm-1600mm-1800mm-2500mm-3000mm-40000mm-6000mm-8000mm

Layer structure: Single layer or multi-layer

Capacity: 200kg/h-1200kg/h

Application: Packaging, construction, water-proof, water-drainage, Geomembrane film, etc.

6. PC/GPPS/PMMA sheet extrusion machine:

Processing material: PC/GPPS/PMMA virgin pellets plus recycle material

Thickness range: 1-12mm

Net sheet witdh: 600mm-1220mm-2100mm(or as per customer's requirement)

Layer Structure: Single layer or multi-layer

Capacity: 200-600kg/h

Application: Ads., decoration, roofing, etc.

7. PC/PP/PE hollow profile sheet/ sunshine roofing panel machine:

Processing material: PC/PP/PE virgin material plus recycle material

Thickness range: 2mm-4mm-6mm-8mm-10mm-12mm

Net sheet width: 1220mm-2100mm

Layer structure: Single layer or multi-layer

Capacity:200-600kg/h

Application: Ads. Decoration, roofing, packaging, printing, etc.

8. PVC sheet/edge banding sheet/marble sheet machine:

Processing material: PVC power plus other additive

Thickness range: 0.15-1mm; 1-3mm; 3-12mm

Net sheet width: 650mm-2000mm-3000mm( or as per customer's requirements)

Layer structure: Single layer or multi-layer

Capacity: 200kg/h-500kg/h

Application: Thermoforming, stationery, printing, payment card, SIM card, construction, etc.

9. PVC free foam/celuka foam board extrusion line

board width: 1220mm, thickness: 1-10mm, 3-25mm

board application: decoration board, advertising boards, exhibition boards

extruder model: SJ-80/156 conical twin screw extruder

max capacity: 350kg/h

certifications: CE, ISO9001-2008

10. EVA car interior decoration sheet extrusion line

Processing material: EVA and other additives

Thickness range: 1-8mm

Width range: 1000-1800mm

Layer strcuture: single layer

Capacity: 700-800kg/h

Application: automotive sealing strips, sound insulation cushion, sound absorption sheets,

automobile tail box, fenders, car interior and exterior decoration parts etc.

11. PVC+PMMA Glazed roofing tiles/corrugated sheet extrusion machine

Processing material: PVC, PMMA and other additives

Thickness range: 1-8mm

Width range: 720mm, 880mm, 1040mm

Layer structure: A/B, A/B/A, A/B/C

Capacity: 400kg/h

Application: garden-style factory, tourist scenic spots, pavillions, hotels, family building etc.