Complete Waste Plastic Film/Bag Recycling Machine

Jiangsu Faygo Union Machinery Co., Ltd.- Material Processed:Plastic Films,Bags

- Plastic Type:PP, PE, LDPE, LLDPE

- Screw:Single-Screw

- Automation:Automation

- Computerized:Computerized

- Certification:ISO9001:2008, CE

Base Info

- Model NO.:FGR300

- Usage:Recycle PP PE Films, Bags

- Final Output:Clean PP PE Scraps, or Granules

- Capacity:300kg,H, 500kg,H, 1000kg,H

- Motor:Siemens Standard Motor

- Electrics:World Brand Electrics

- Transport Package:Wood Packing with Protecting Film

- Specification:25m x 2m x 4.2m

- Trademark:FAYGO

- Origin:Chinese

- Production Capacity:100 Sets Per Month

Description

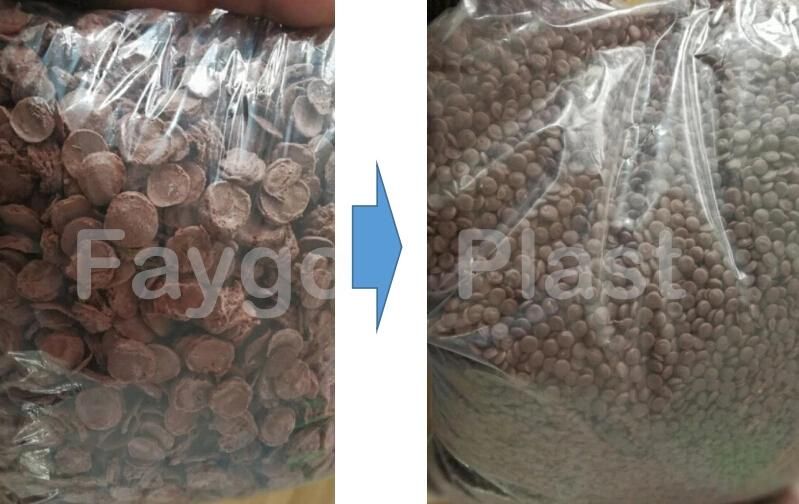

For plastic films, now we will suggest squeezing pelletizing system after the washing line. This system can replace the centrifuge dewatering machine, pipeline drying system, agglomerator. People can save a lot of electricity and space with this squeezing pelletizer. It can get more dry material from washed PP, PE film/bag scraps. Besides, it can also easy to acchieve high output like 500~800kg/h. With this squeezing pelletizing system, the clients will get the rigid PP PE scraps from the washing line and it is much more easy for pelletizing line.

After squeezing pelletzer, the rigid PP, PE flakes will be very hot and the air conveying pipe will be double layer, which will put cooling water inside. We will suggest cooling conveyer after this squeezing pelletizing machine. The rigid flakes can put into simple pelletizing line to make good granules.