Plastic Waste PP Woven Bag Jumbo Ton Bag LDPE HDPE PE Film Double Stage Die Face Water ...

Zhangjiagang Conbo Machinery Co., Ltd.- Raw Material:PE

- Screw:Single-Screw

- Inverter:Inverter

- Electromagnetic Heater:Electromagnetic Heater

- Automation:Automatic

- Computerized:Computerized

Base Info

- Model NO.:CB-R-500

- Customized:Customized

- Certification:CE, ISO9001:2008

- Condition:New

- Plastic Processed:PE Materials, PP Woven Bag

- Speed Control:by ABB Inverter

- Motor Brand:Siemens or Top Local Quality

- Electrical Components:Siemens, ABB, Schneider, Omron, FUJI, etc.

- Delivery Time:60 Workdays

- Guarantee Period:One Year

- Water-Ring Cutting:Vertical or Horizontal Die Head

- Material of Dewatering Machine:SUS304

- Feeding Mode:by Conveyer Belt

- Control by:Siemens PLC Screen Touch

- Transport Package:Plastic Film and Wooden Box

- Specification:Capacity upto 1000kg,hr

- Trademark:CONBOPLAS

- Origin:Zhangjiagang

- HS Code:84778000

- Production Capacity:10 Sets Per Month

Description

Basic Info.

Model NO. CB-R-500 Customized Customized Certification CE, ISO9001:2008 Condition New Plastic Processed PE Materials, PP Woven Bag Speed Control by ABB Inverter Motor Brand Siemens or Top Local Quality Electrical Components Siemens, ABB, Schneider, Omron, FUJI, etc. Delivery Time 60 Workdays Guarantee Period One Year Water-Ring Cutting Vertical or Horizontal Die Head Material of Dewatering Machine SUS304 Feeding Mode by Conveyer Belt Control by Siemens PLC Screen Touch Transport Package Plastic Film and Wooden Box Specification Capacity upto 1000kg/hr Trademark CONBOPLAS Origin Zhangjiagang HS Code 84778000 Production Capacity 10 Sets Per MonthProduct Description

Brief Introduction:1. The line is special equipment for the PE materials and PP woven bag recycling granulating, it equipped with compacting machine which could pre- compact the film into smaller granules, then easily feed into screw barrel of extruder, ensure high capacity and save labor.

2. It has two vacuum exhausting mouth on extruder barrel which can fully vent the moisture in the material and the final granule quality will be very perfect.

3. At the end of screw barrel, it equipped with double post fast speed hydraulic non -stop screen changer which can effectively filt out the dirty in the plastic melt.

4. The pelletizing adopts water flush pelletizing which is easier to operate, and the shape and appearance of granule is good.

Application raw materials:

PE, HDPE, LDPE, LLDPE, Stretch film, PP Non woven fabric, Woven bags, etc.

Technical Specifications:

| Item/Model | CB-R-80 | CB-R-100 | CB-R-120 | CB-R-160 |

| Main driving motor | 55 | 90 | 132 | 200 |

| L/D ratio | 40:1 | 36:1 | 33:1 | 30:1 |

| Output (kg/h) | 150-200 | 250-350 | 400-500 | 800-1000 |

Notice:Our single stage is suitable for clean film material, if your material is not clean enough, I would like to recommend you the double stage pelletizing line. If your material is very dirty the it should be washed first, we can also supply you our film washing line.

More details of the machinery:

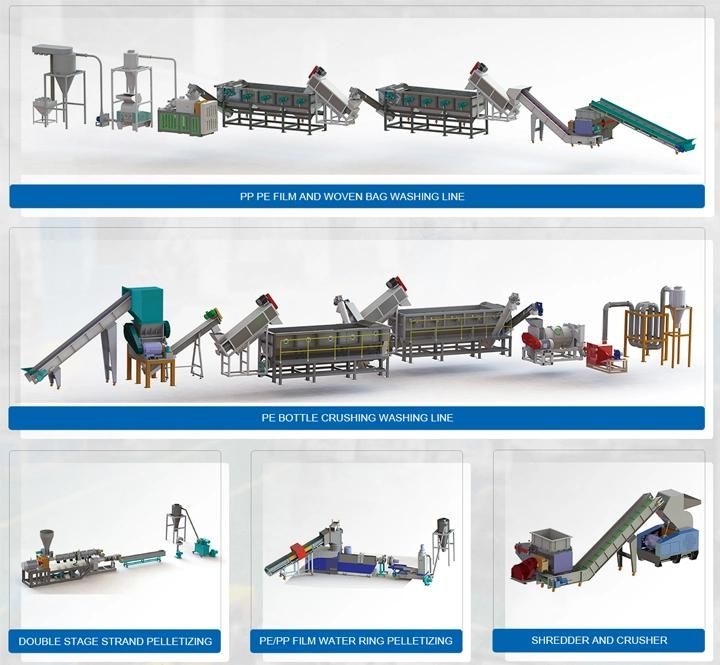

Related machinery offered:

Business cooperation and Certificates:

Manager: BOSH LEUNG (MR.)

Company website: http://conboplas1986.en.made-in-china.com

Address: Leyu Development Zone, Zhangjiagang city, Jiangsu Province, China.