PP PS PE Sheet Plate Board T-Die Extrusion Machine

Qingdao Hanhai Plastic Machinery Co., Ltd.- Product Type:PP Board

- Board Layers:Multilayer

- Screw No.:Single-screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE

Base Info

- Model NO.:SJ120,33

- Customized:Customized

- Condition:New

- Motor:Simens Beide

- PLC:Simens

- Sheet Width:600-2200mm

- Sheet Thickness:0.2mm-50mm

- Weight:8-15ton for Plastic Sheet Extrusion Line

- Application:Plastic Sheet Making Machine for Package or Folder

- Raw Material:PP,PE,ABS,HIPS Granule

- Other Name:Plastic Sheet Extrusion Line

- Other Name1:Plastic Sheet Extrusion Machine

- Other Name2:PE Sheet Production Line

- Other Name3:PP Sheet Making Machine

- Other Name4:ABS Sheet Making Machine

- Other Name5:HIPS Sheet Making Machine

- Other Name6:Plastic Board Extrusion Line

- Other Name7:HDPE Thick Board Machine

- Transport Package:by Sea

- Specification:20m*2m*2.5m

- Trademark:Hanhai

- Origin:Qingdao, China

- HS Code:84772090

- Production Capacity:30-50 Sets Per Year

Description

1set

2.Specification for plastic plate making machine price

2.Specification for plastic plate making machine price

- Roller diameter

Upper roller mm Ø480 Middle roller mm Ø480 Bottom roller mm Ø480 Roller length mm 1300 The thickness of chrome surface mm 0.1- 0.12 Surface chrome conditions class 12 No. of rollers Pcs 3 Max. Linear speed m/min 2.2 Driving motor power kw 2.2 Driving motor quantity Pcs 3 Moving motor power kw 0.75 Max. elevating dist. Of upper

or bottom rollermm 50

5. cooling bracket: length: 6000mm;

6. haul-off unit: Performance features:- A pair of rubber rollers haul off

- Speed adjustable control, the up and down rollers are synchronized via drive unit

- With emergency stop

- Electric part with CE certificate

- With laminating system

Min. m/min 1.5 Max. m/min 15 Towing motor kw 2.2 Width without edge mm Up to 1050

7.Saw Cutter

Performance features:- The machine is manufactured according to EU Norms.

- Adjustable machine leveling feet.

- With emergency stop.

- Low energy consumption.

- Low noise design.

Min mm 4 Max. mm 4 Width of the sheet mm 1050

8.Final product bracket

3.You just tell me what machine you want,let us do the rest work:

1. Design and manufacture suitble machine for you.

2. Before delivery, we will test the machine until you are completely satisfied. (You can come to our factory to inspect the running production line.)

3. Delivery.

4. We will provide after-sales service:

(1) Field installation and commissioning;

(2) Field training your workers; (3) Field maintenance and repair service ;

(4) Free Spare Parts ;

(5) Video/Online technical support.

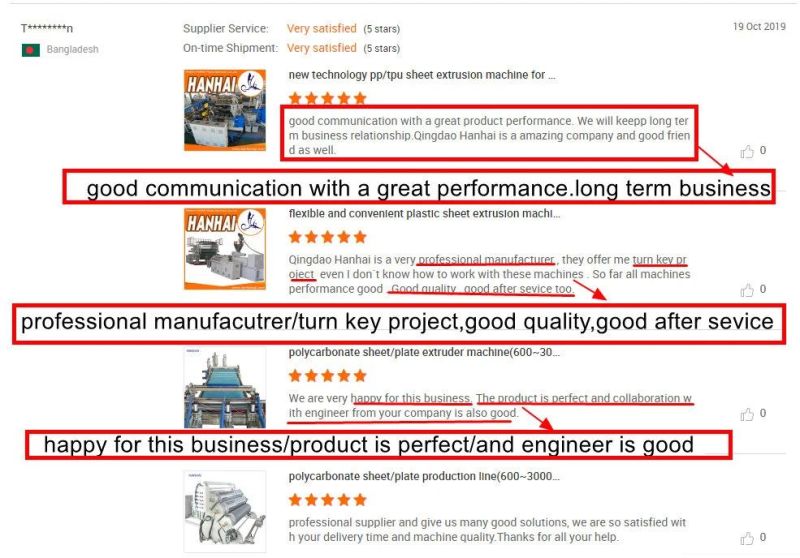

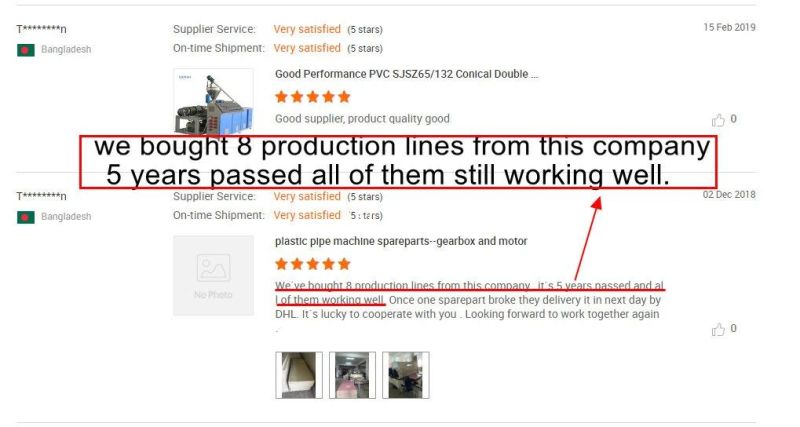

4.Reviews by customers

5.Cooperation Brands

6.FAQ:

1.Are you manufacturer or trading company?

We are manufacturer.

2.Why choose us?

We have 20 years experience for producing machine.We can arrange for you to visit our local customer's factory.

3.Delivery time: 20~30 days.

4.Payment terms:

30% of total amount should be paid by T/T as down payment, the balance (70% of total amount) should be paid before delivery by T/T or irrevocable L/C(at sight).

5.Warranty: 1 year.

7.Contact Us: