Best Price Cold Cut Waste PP PE Recycle Granule Making Machine

Qingdao Tongsan Plastic Machinery Co., Ltd.- Raw Material:PE, Waste Plastic, Industrial Leftover, Recycled PP PE

- Screw:Single-Screw

- Inverter:Inverter

- Electromagnetic Heater:Electromagnetic Heater

- Automation:Automatic

- Computerized:Computerized

Base Info

- Model NO.:SJMS-60 65 72 75 95

- Customized:Customized

- Certification:CE, ISO9001:2008, QS

- Condition:New

- Voltage:380V,as Customer Request

- Extruder Diameter:60,65,72,75,95mm

- Granulating Capacity:100-800kg,Hour

- Power(W):75-130kw

- Screw Quantity:2

- L/D Radio:28-45

- Capacity:90-900kg,H

- Transport Package:Stanred Packing

- Specification:15mx2mx2.5m

- Trademark:TONGSAN

- Origin:Shandong China

- Production Capacity:5sets, Month

Description

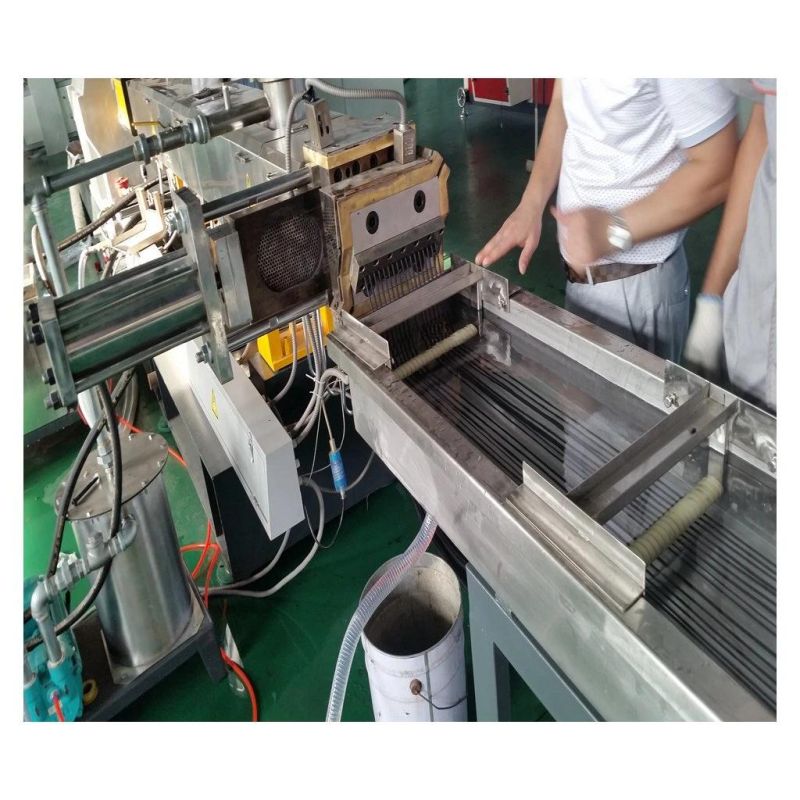

Main Features on Plastic Cold Cut Recycled Pelletizing Granulator Extrusion Machine

1)The parallel twin-screw pelletizing adopts modular construction, with advantages of all gear-closing and strong self-cleaning.

2)The granulating barrel has a good exhaust effect. The bi-metal alloy bushing is of war-resistance and corrosion-resistance.

3) The machines can be combined free according to the characteristics of materials and production process, so it is widely use.

4) Granulating die head is made from high-quality mould steel, under hard chrome plating treatment. The reasonable-distributed material running channel can ensure the uniform extrusion of the granules without mutual influence.

5) The unique three-dimensional cooling structure and the new-type multi powerful blower cooling mode make the cooling effect better.

6)Besides, the pelletizer precise cutter ensures the even and smooth surface of the products. The speed frequency regulation meets different material granulating requirement.

Main Features on Plastic Cold Cut Recycled Pelletizing Granulator Extrusion Machine

1)The parallel twin-screw pelletizing adopts modular construction, with advantages of all gear-closing and strong self-cleaning.

2)The granulating barrel has a good exhaust effect. The bi-metal alloy bushing is of war-resistance and corrosion-resistance.

3) The machines can be combined free according to the characteristics of materials and production process, so it is widely use.

4) Granulating die head is made from high-quality mould steel, under hard chrome plating treatment. The reasonable-distributed material running channel can ensure the uniform extrusion of the granules without mutual influence.

5) The unique three-dimensional cooling structure and the new-type multi powerful blower cooling mode make the cooling effect better.

6)Besides, the pelletizer precise cutter ensures the even and smooth surface of the products. The speed frequency regulation meets different material granulating requirement.

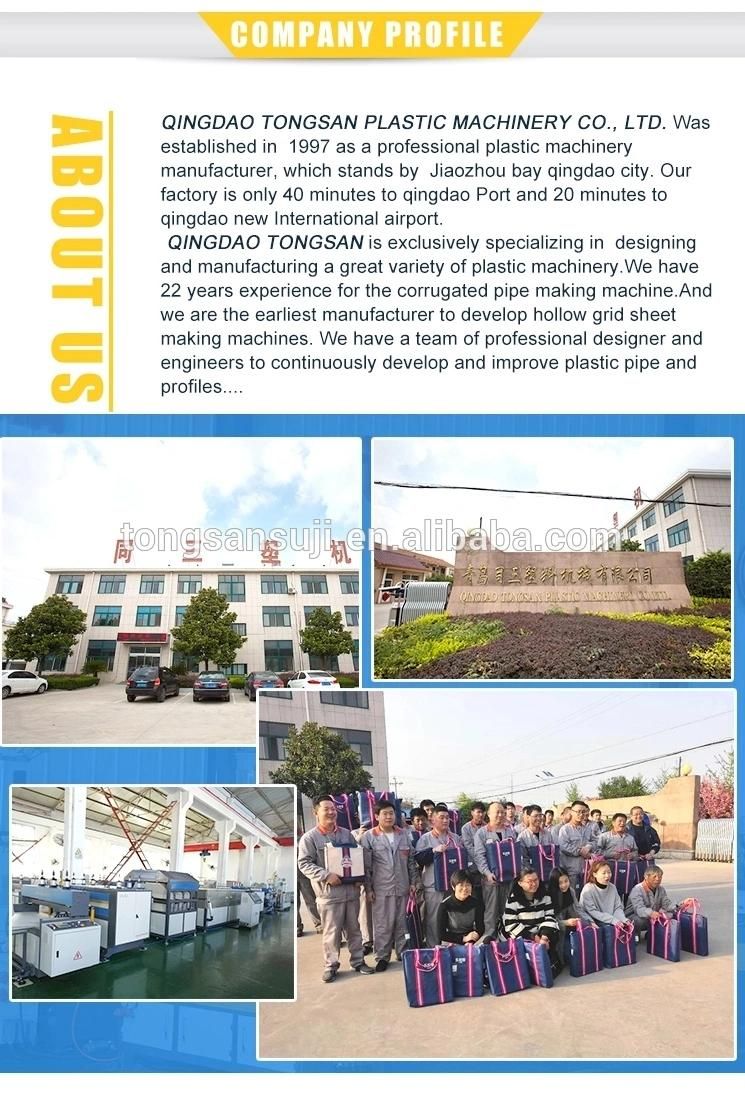

Be Our Client:

Why Choose us?

FAQ:

IF YOU HAVE ANY MORE QUESTIONS PLEASE CLICK ''SENT THE MASSAGE '' TO ME. ^-^