XLPE Silane Cross-Linked Cable Compounds / Plastic Plastic Masterbatch Filling and ...

Jiangsu Xinda Tech Limited- Warranty:1 Year

- Raw Material:Mixing

- Screw:Single-Screw

- Inverter:Inverter

- Electromagnetic Heater:Electromagnetic Heater

- Automation:Automatic

Base Info

- Model NO.:SJW-140

- Computerized:Computerized

- Customized:Customized

- Certification:CE, ISO9001:2008, QS, UL

- Condition:New

- Capacity:700-800kg,H

- Applications:All Kinds of Polymer Mixing

- Electric Brands:Siemens , Schneider

- Control:PLC + Touch Screen

- Extruder Weight:10000kg

- Transport Package:Pallet and Wooden Box

- Trademark:XINDA

- Origin:China

- HS Code:84772010

- Production Capacity:200sets,Year

Description

Basic Info.

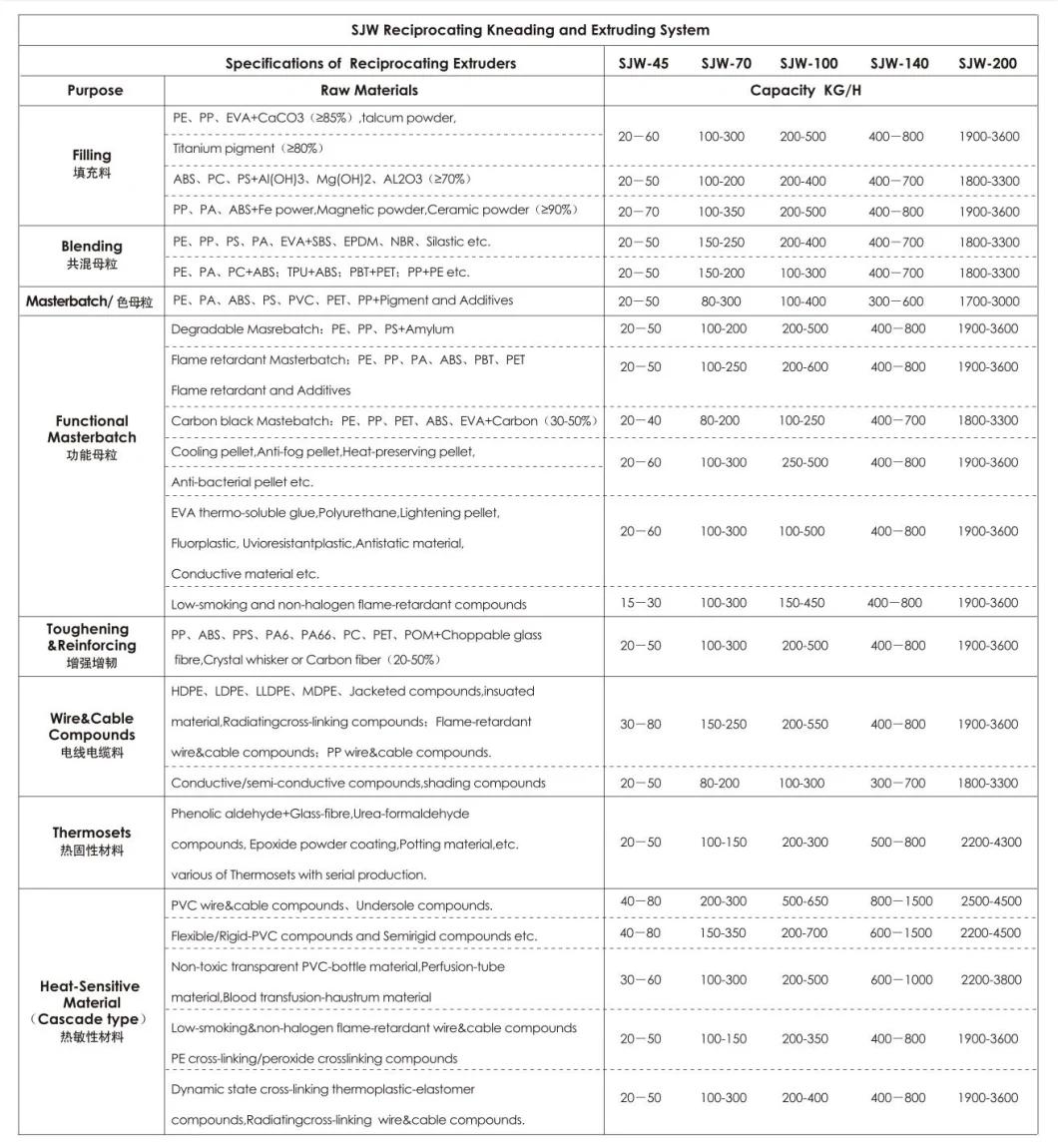

Model NO. SJW-140 Computerized Computerized Customized Customized Certification CE, ISO9001:2008, QS, UL Condition New Capacity 700-800kg/H Applications All Kinds of Polymer Mixing Electric Brands Siemens / Schneider Control PLC + Touch Screen Extruder Weight 10000kg Transport Package Pallet and Wooden Box Trademark XINDA Origin China HS Code 84772010 Production Capacity 200sets/YearProduct Description

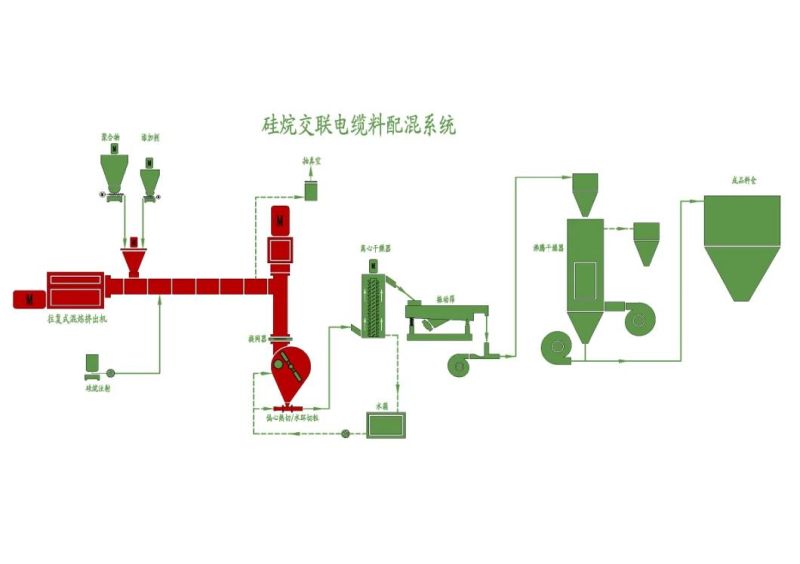

XLPE silane cross-linked XLPE for cable applications:

Polyethylenes (PE) have outstandingly good insulation properties. A temporary temperature rise, e.g. due to peak loading, can however cause a complete breakdown of PE cable insulation. The relatively low softening or melting point leads to thermo-mechanical failure or even dripping of the Insulation. Cross-linked polyethylene (PEX) is more thermosetting than thermoplastic. It can therefore be used at significantly higher operating temperatures, is mechanically stronger, more resistant to organic liquids, and often enables thinner wall thicknesses. Various cross-linking methods are used. Silane cross-linkable cable compounds are also known as PEX-b or Sioplas®.

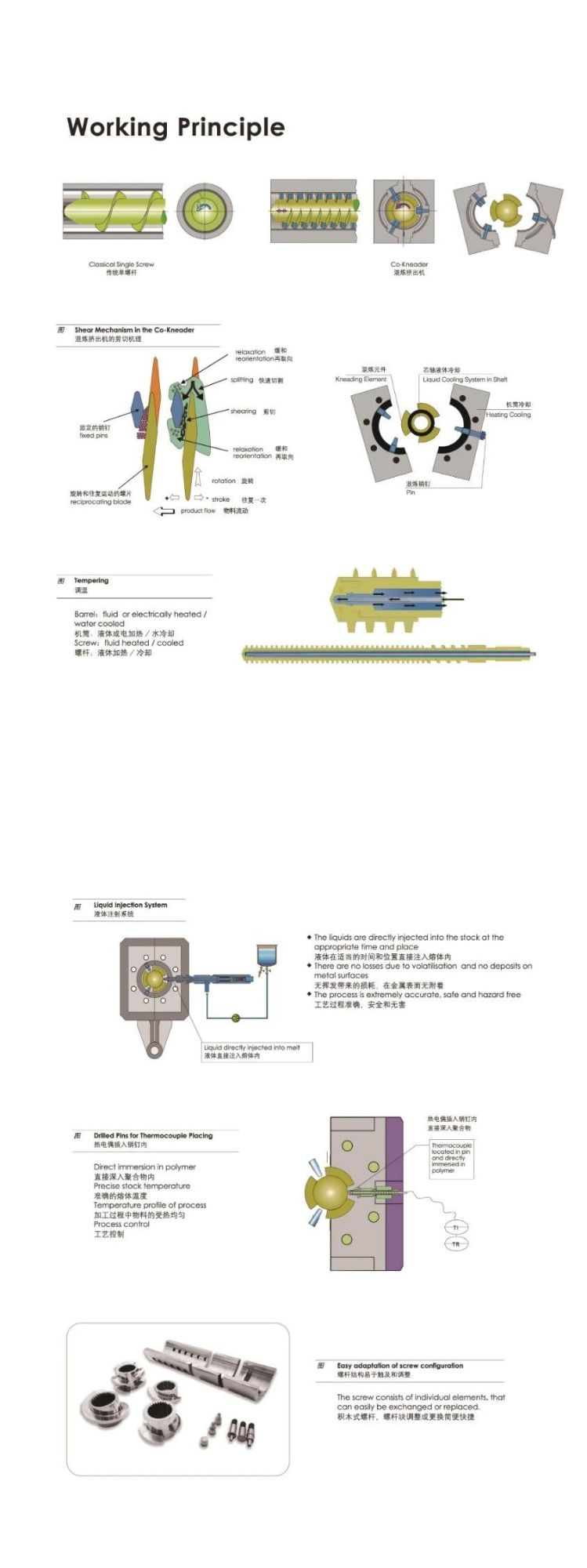

On XINDA Co-kneader, customer can realize:

1, the grafting process needs a precise tempeature control, while co-kneader can detect polymer tempeature

2, a liquid silane can be injected to melted polymer from the hollow pins

3, good distribution and dispersion can be realized

SJW XINDA Type Cascade Three Flights Co-Kneader Compound Extruder for XLPE silane cross-linked cable Compounds

Advantages of the XINDA Co-kneader

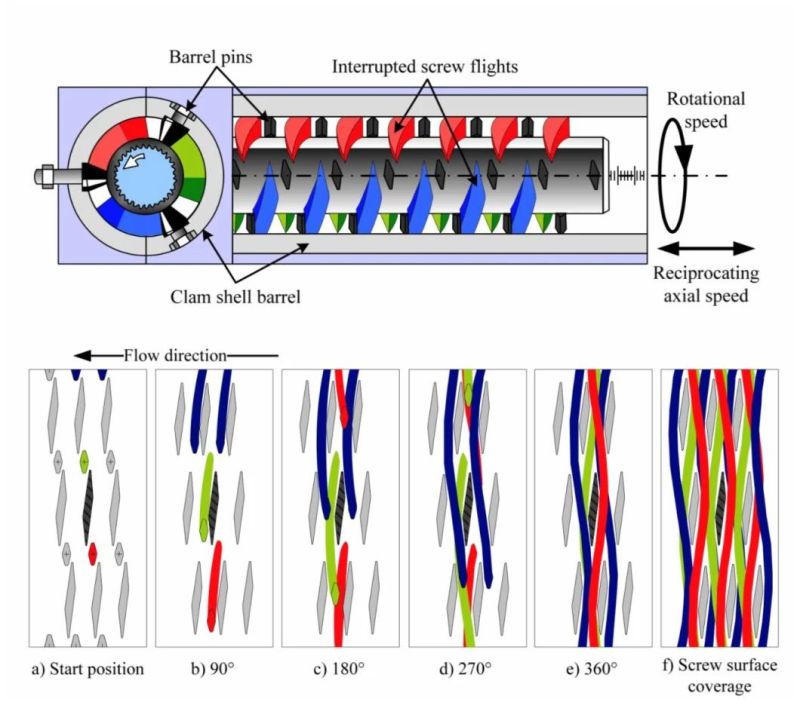

The Co-Kneader, a mild-shear rotating and reciprocating single-screw extruder, is designed for shear and temperature sensitive compounds. The flights on the screw are interrupted and interqct with three rows of stationarv kneadina pins located in the barrel wall. The interaction between the moving flights and the stationary pins provide dispersive and distributive mixing simultaneously. Axially opened split barrel guarantees ease of cleaning. Those splined, segmented screw elements and pins can be changed easily according to different processing techniques. In addition, some pins are hollow inside, thermocouples can be inserted to get the accu- rate temperature of the materials inside the barrels, so as to liquid additives injection. Different from other extruders, the kneading process is achieved radially and axially at the same time. All in all, Co-Kneader has outstanding kneading, mixing efficiency and high degree of self-wiping. It is the most suitable for compounding purposes.

--Extremely homogeneous mixing, no shear spikes, equal treatment of polymer matrix

--High degree of self-wiping and have no dead spot

--Dispersive mixing without destroying delicate fllers

--High volumetric loadings of fllers and additives

--Efficient blending of liquid components

--Broad application for compounding without changing hardware

--Axially opened split barrel guarantees ease of cleaning and fast maintenance

--Replacement parts, such as screws, barrel lining and pins can be changed individually

Silane cross-linked XLPE Compounds:

Details Images