PVC Soft Pipe Making Machine Plastic Garden Hose Production Line

Zhangjiagang Camel Machinery Co., Ltd.- Warranty:1 Year

- Product Type:PVC Pipe

- Screw No.:Double-screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008

Base Info

- Model NO.:PPL

- Customized:Customized

- Condition:New

- After-sales Service:on-Site Installation, Testing and Training

- Name:PVC Soft Pipe Making Machine Garden Hose Make Line

- Inverter:ABB,Holip

- Motor:Siemens Beide,Weg

- Raw Material:PVC Resin+PP Yarn

- Contactor:Siemens Contactor

- Color:Customised

- Temperature Controller:Rkc,Omron

- Usage:Water Pipe, Garden Hose

- Voltage:220V 380V 400V 415V 440V(Customized)

- Gearbox:Guomao Brand

- Fiber Design:Knitting Fiber

- Pipe Layer:1 Layer, 3layer, 4layer, 5layer

- Transport Package:Standard Shpping Package

- Specification:25mx2.5mx2.2m

- Trademark:CAMEL

- Origin:China(Mainland)

- HS Code:84772090

- Production Capacity:800 PCS,Year

Description

Basic Info.

Model NO. PPL Customized Customized Condition New After-sales Service on-Site Installation, Testing and Training Name PVC Soft Pipe Making Machine Garden Hose Make Line Inverter ABB/Holip Motor Siemens Beide/Weg Raw Material PVC Resin+PP Yarn Contactor Siemens Contactor Color Customised Temperature Controller Rkc/Omron Usage Water Pipe/ Garden Hose Voltage 220V 380V 400V 415V 440V(Customized) Gearbox Guomao Brand Fiber Design Knitting Fiber Pipe Layer 1 Layer, 3layer, 4layer, 5layer Transport Package Standard Shpping Package Specification 25mx2.5mx2.2m Trademark CAMEL Origin China(Mainland) HS Code 84772090 Production Capacity 800 PCS/YearProduct Description

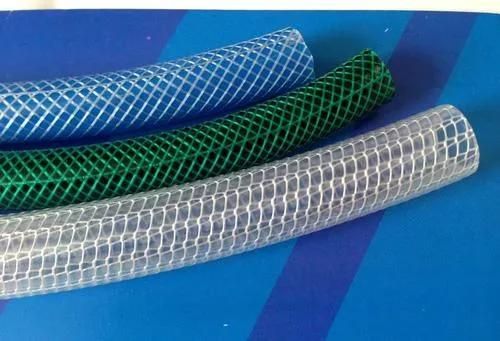

PVC Soft Pipe Making Machine plastic Garden Hose Production LineWhat is the feature of our PVC fiber reinforced Hose Mahcine

1. High efficiency single screw extruder

2. It can produce PVC garden hose or pvc soft hose

3. The thickness is from 2mm to 6mm, diameter is from 10mm to 50mm

4. This pvc hose is mostly used as home, garden, farm, lawn and so on.

Flow chart

Material mix inner --layer extrusion inner-- layer forming→ spray cooling→ haul off→ fiber winding→ oven dryness→ outer layer extrusion→ outer layer forming→ spray cooling→ haul-off→ printer→ winder

Technical Parameters

| Model | L/D Ratio | Screw | Material | Screw diameter | Output | Total Power | Center Height | Production Scale |

| SJ45/30 | 30:1 | Separative style | 38CrMoal | 45mm | 60kg/hr | 35kw | 1000mm | Φ6-16mm |

| SJ65/30 | 30:1 | Separative style | 38CrMoal | 65mm | 120kg/hr | 50kw | 1000mm | Φ16-50mm |

Main Composition

| Item | Quantity |

| SJ65/30 Single Screw Extruder | 2sets |

| Die and Mold | 1set |

| Stainless steel cooling tank | 2sets |

| Knitting Machine | 1set |

| Haul off machine | 2sets |

| Auto Winder | 1set |

Detailed image

OUR COMPANY

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 45-60 days if the goods are not in stock, it is according to what kind of machine you need

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: 30% T/T in advance ,70% balance before shipment or Negotiable

If you have another question, please feel free to contact us as below