Htf1000t Ma1000 Bimetallic Screw and Barrel for Injection Molding Machine

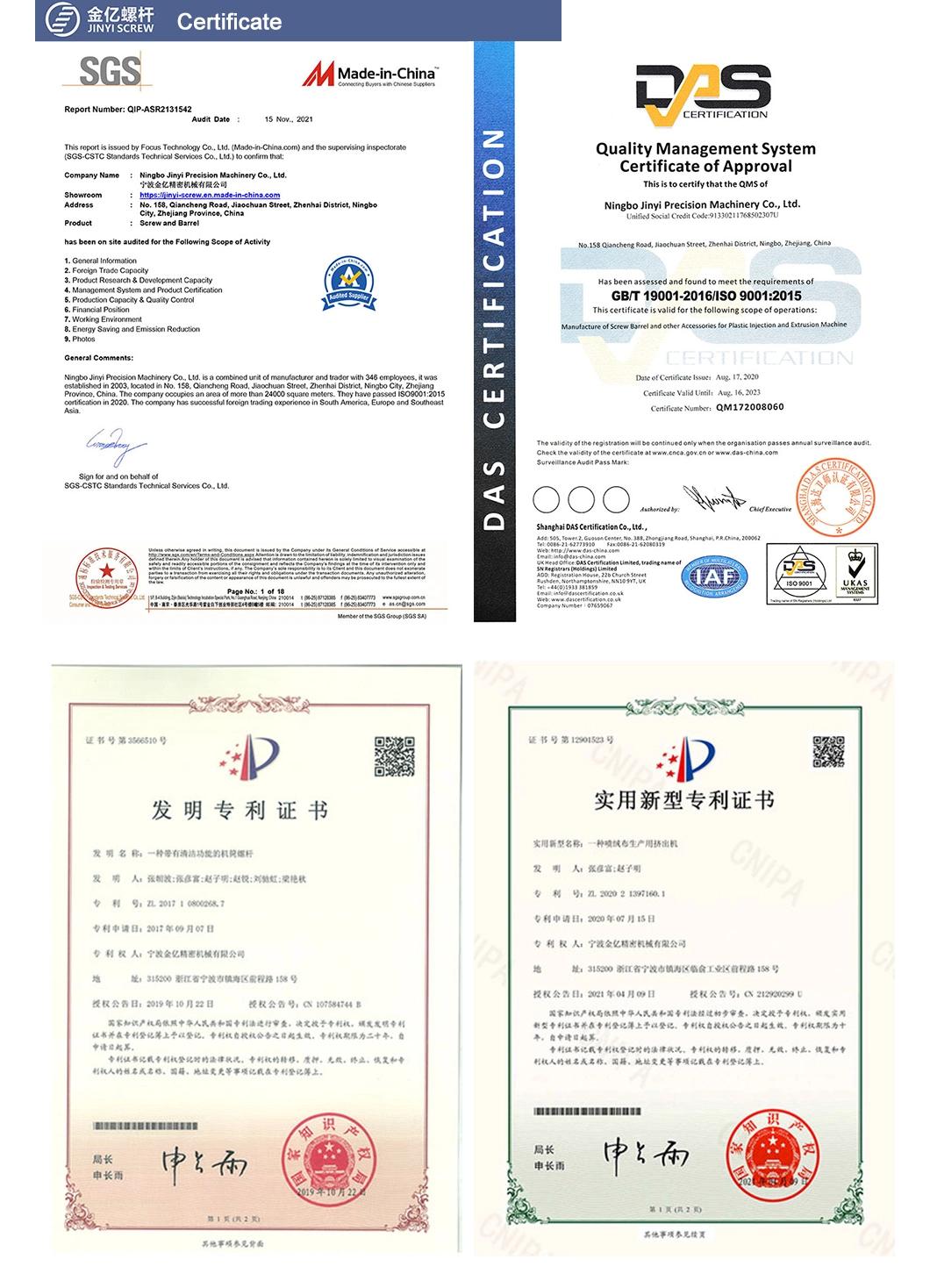

Ningbo Jinyi Precision Machinery Co., Ltd.- After-sales Service:Online

- Warranty:12 Months

- Standard:DIN, ASTM, GOST, GB, JIS, ANSI, BS

- Technics:Machining

- Feature:Durable

- Material:Alloy Steel

Base Info

- Model NO.:JYSS06

- Max. Screw Dia:500mm

- Injection Volumn:30g-25000g

- Clamping Force:250-35000kn

- Appliance:PVC, ABS, PP, PE, PA, PC, EVA, PS, POM, etc

- Base Material:38CrMoAl, 42CrMo, 40cr, SKD11, SKD61, SUS440b, etc

- Treatment:Gas Nitrition, Chrome-Plate, Pta Spraying, etc

- Transport Package:Seaworthy Wooden Case

- Specification:d16~d500mm

- Trademark:JINYI

- Origin:Ningbo

- HS Code:84779000

- Production Capacity:2000 Sets,Month

Description

Product FeaturesBrand JINYI Product Name Bimetallic Screw Base Material 38CrMoAlA High-quality Alloy Structural Steel Bimetallic Material JYS01(Ni,Cr,Si), JYS02(Ni,Cr,W), JYS03(Co,Cr,W) Quenching and Tempering Hardness HB260-280 Nitriding Hardness HV950±50 Nitride Layer Depth & Hardness 0.4-0.6mm , 56-60HRC Brittleness ≤2 Surface Finish Ra0.04 Scope of Application Suitable Recycling & Engineering Plastics & < 20% reinfored additives & corrosive plastic

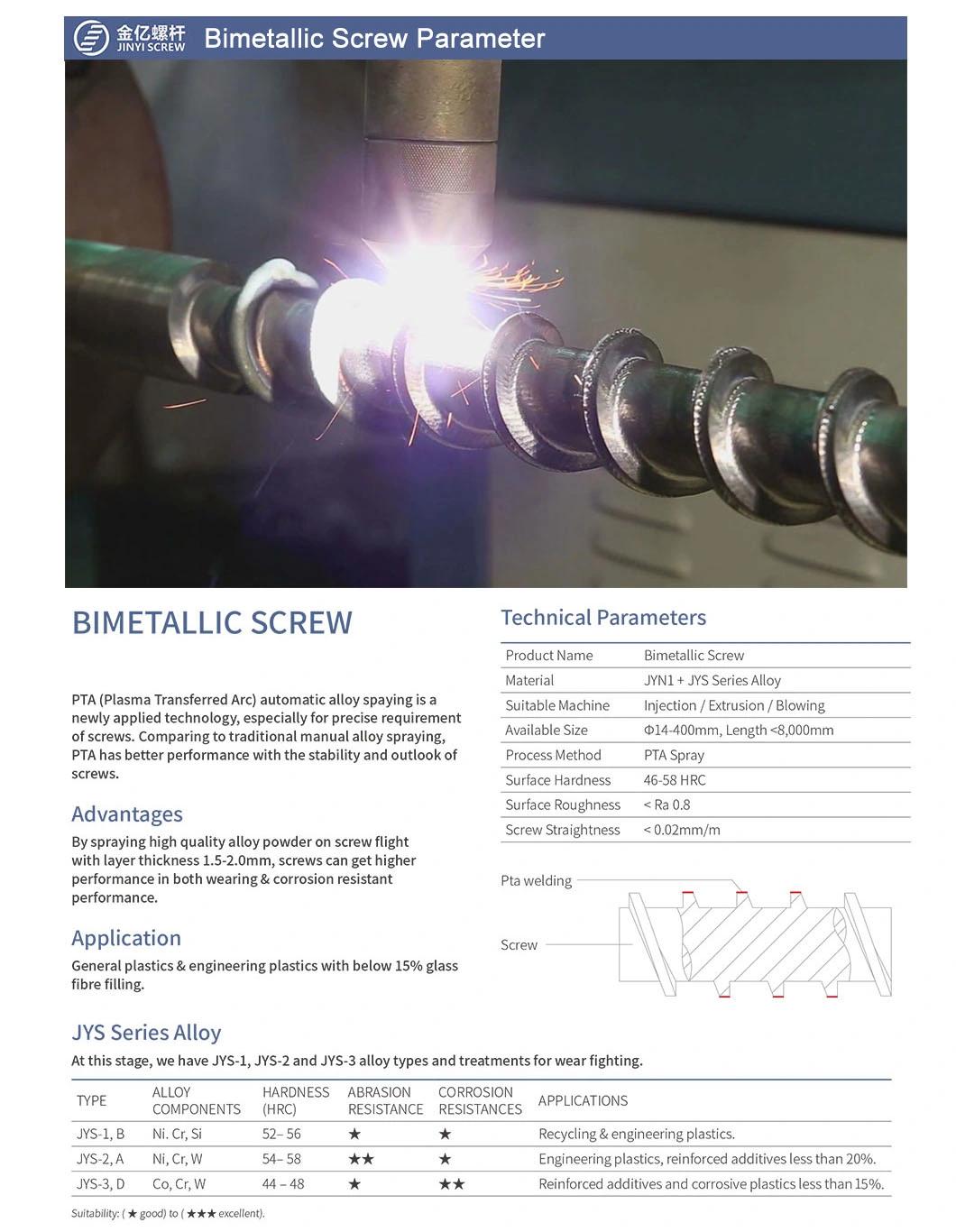

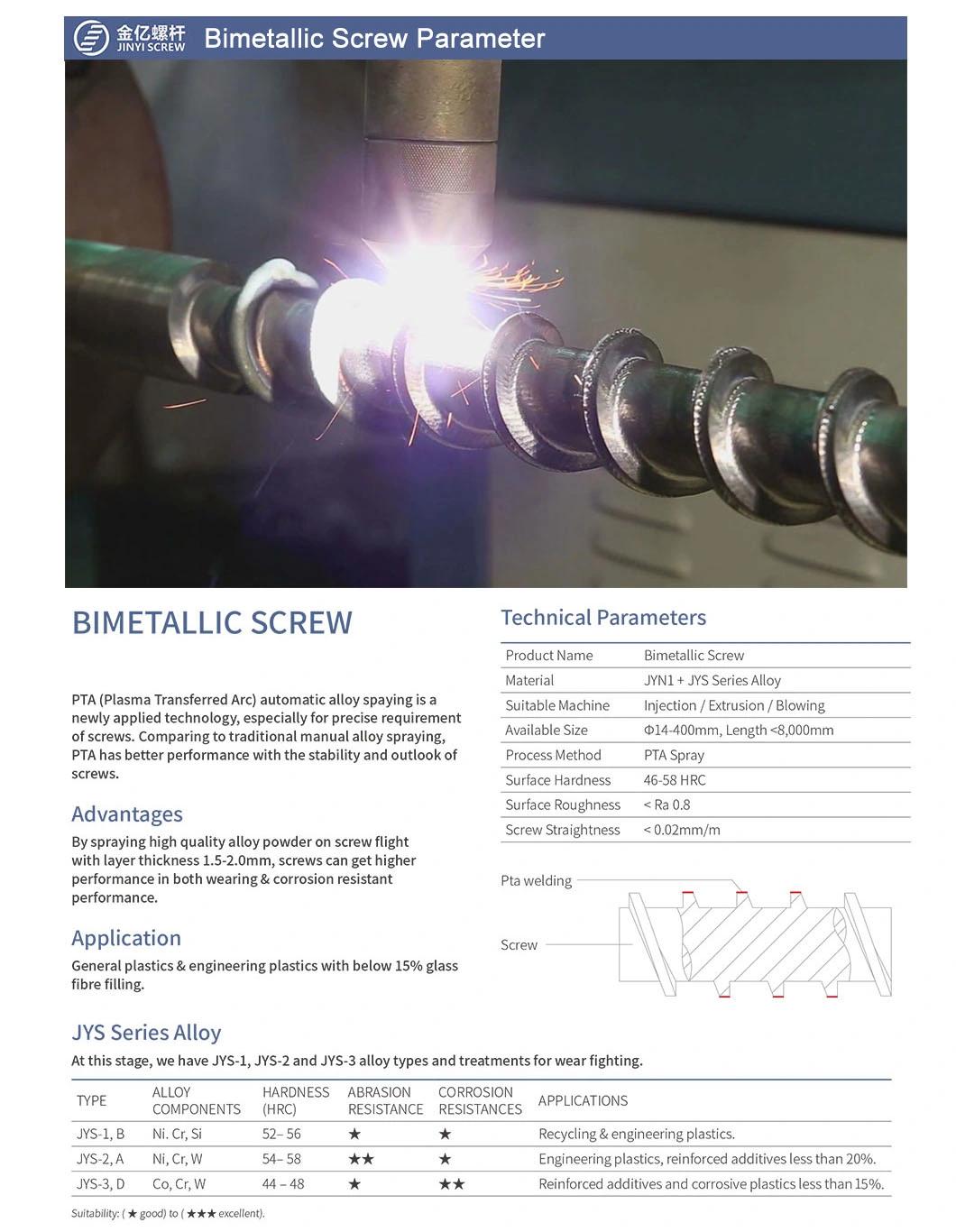

Bimetallic Screw

PTA (Plasma Transferred Arc) automatic alloy spaying is a newly applied technology, especially for precise requirement of screws. Comparing to traditional manual alloy spraying, PTA has better performance with the stability and outlook of screws.

Technical Parameters

Product Name : Bimetallic Screw

Material : JYN1 + JYS Series Alloy

Suitable Machine: Injection / Extrusion / Blowing ...

Available Size: Φ14-400mm, Length <8,000mm

Process Method: PTA Spray

Surface Hardness:46-58 HRC

Surface Roughness: < Ra 0.8

Screw Straightness: < 0.02mm/m

Advantages

By spraying high quality alloy powder on screw flight with layer thickness 1.5-2.0mm, screws can get higher performance in both wearing & corrosion resistant performance.

Application

General plastics & engineering plastics with below 15% glass fibre filling.

JYS Series Alloy

At this stage, we have JYS-1, JYS-2 and JYS-3 alloy types and treatments for wear fighting.

Suitability: (x good) to (xxx excellent).

FAQ:

Q1. What's your MOQ?

1PC or SET

Q2. Can I place the customized order for different sizes, materials, structure….?

Yes, all customized orders are welcomed.

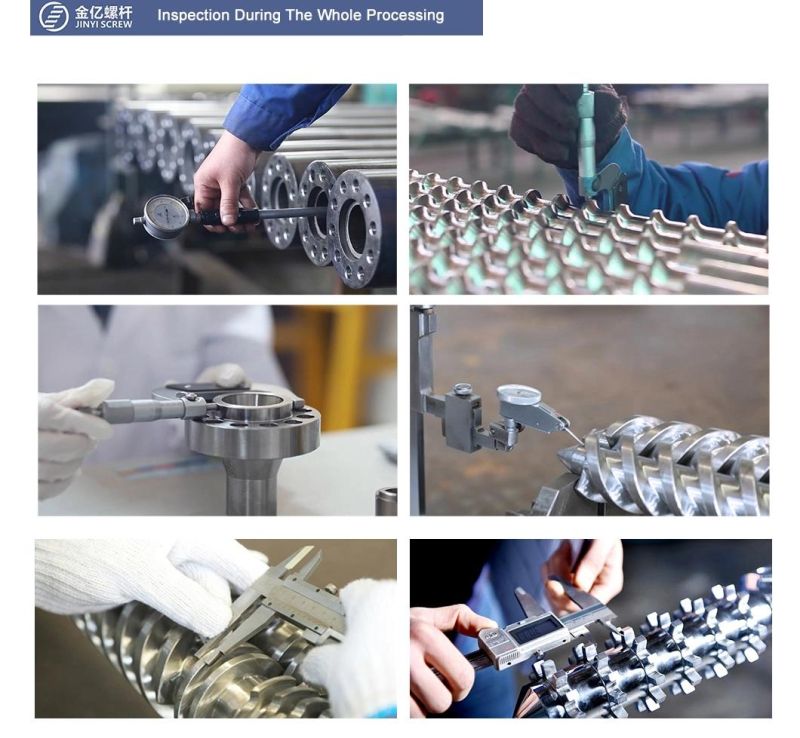

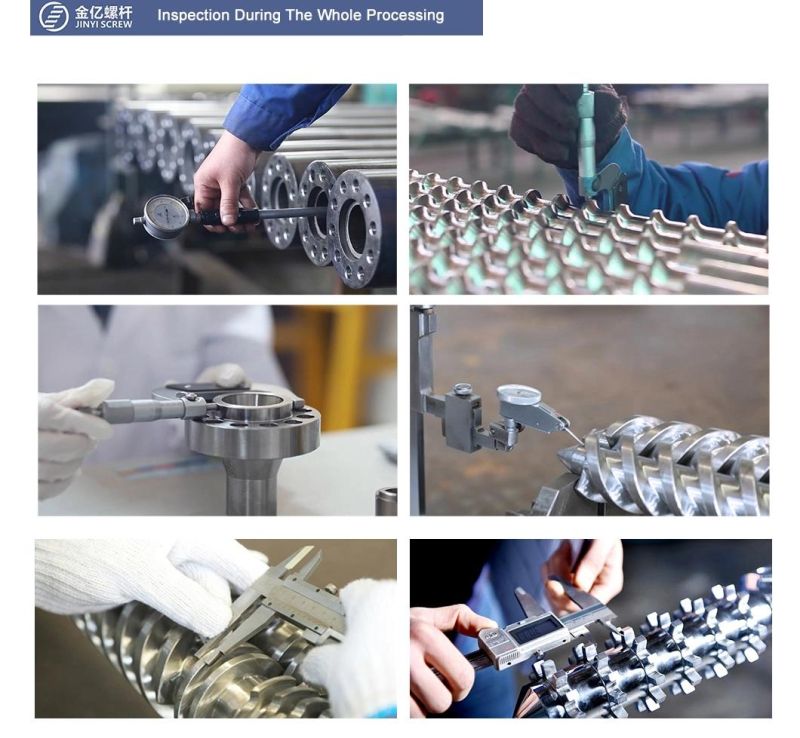

Q3. Could I get a QC report before delivery?

Yes, the specific QC reports will be sent to you before delivery.

Q4. Can I have our own logo or label on our product?

Yes,we can laser your logo or code number on your product.

Q5. How long is your guarantee?

1year,2 years,5 years base on different requirement.

Q6. How to reach you for other questions?

Please feel free to contact us through E-mail, call or visiting our factory as below address.

Bimetallic Screw

PTA (Plasma Transferred Arc) automatic alloy spaying is a newly applied technology, especially for precise requirement of screws. Comparing to traditional manual alloy spraying, PTA has better performance with the stability and outlook of screws.

Technical Parameters

Product Name : Bimetallic Screw

Material : JYN1 + JYS Series Alloy

Suitable Machine: Injection / Extrusion / Blowing ...

Available Size: Φ14-400mm, Length <8,000mm

Process Method: PTA Spray

Surface Hardness:46-58 HRC

Surface Roughness: < Ra 0.8

Screw Straightness: < 0.02mm/m

Advantages

By spraying high quality alloy powder on screw flight with layer thickness 1.5-2.0mm, screws can get higher performance in both wearing & corrosion resistant performance.

Application

General plastics & engineering plastics with below 15% glass fibre filling.

JYS Series Alloy

At this stage, we have JYS-1, JYS-2 and JYS-3 alloy types and treatments for wear fighting.

| TYPE | ALLOY COMPONENTS | HARDNESS (HRC) | ABRASION RESISTANCE | CORROSION RESISTANCE | APPLICATIONS |

| JYS-1, B | Ni. Cr, Si | 52- 56 | x | x | Recycling & engineering plastics. |

| JYS-2, A | Ni, Cr, W | 54- 58 | xx | x | Engineering plastics, reinforced additives less than 20%. |

| JYS-3, D | Co, Cr, W | 44 - 48 | x | xx | Reinforced additives and corrosive plastics less than 15%. |

FAQ:

Q1. What's your MOQ?

1PC or SET

Q2. Can I place the customized order for different sizes, materials, structure….?

Yes, all customized orders are welcomed.

Q3. Could I get a QC report before delivery?

Yes, the specific QC reports will be sent to you before delivery.

Q4. Can I have our own logo or label on our product?

Yes,we can laser your logo or code number on your product.

Q5. How long is your guarantee?

1year,2 years,5 years base on different requirement.

Q6. How to reach you for other questions?

Please feel free to contact us through E-mail, call or visiting our factory as below address.