Rigid Plastic Post Industrial Film Construction Film Crushing Shredder for Plastic ...

Wuxi DGM Environmental Technology Co., Ltd.- Type:Powerful Plastic shredders

- Raw Material:HDPE

- Structure:Top Feed

- Knife Classification:Claw Knife Crusher

- Knife Roll:Hollow Knife Roller

- Automation:Automatic

Base Info

- Model NO.:DGS

- Computerized:Computerized

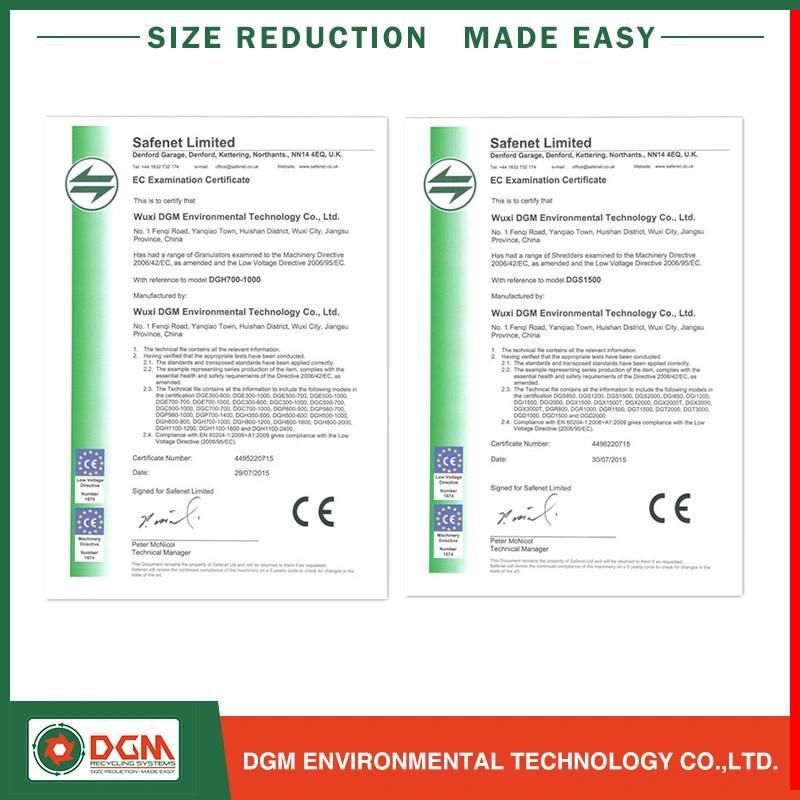

- Certification:CE, ISO9001:2008, BV

- Motor:Weg

- Gear Box:Sew

- Electronic Components:Kloeckner Moeller

- Safety Switch:Schmersal

- PLC Cabinet:Rittal

- Bearings:Heavy Duty Bearings

- Knives:Knives Are Externally Adjustable

- Rotor:Wide Choice of Rotor Variations

- Stator Knives:2 Set

- Mechanical Material:Q345

- Knife Materials:D2, SKD11

- Rotor Diameter:457mm

- Screen Size:40-100mm

- Transport Package:Stretch Film, Wood Pallet

- Specification:DGX850-2000

- Trademark:DGM

- Origin:Wuxi, China

- HS Code:84778000

- Production Capacity:2000sets Per Year

Description

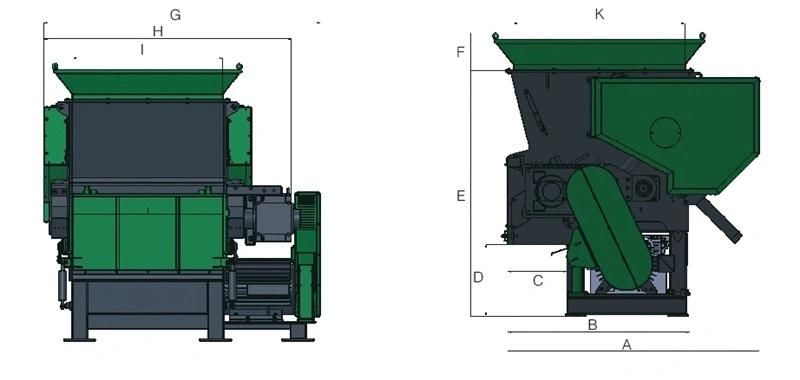

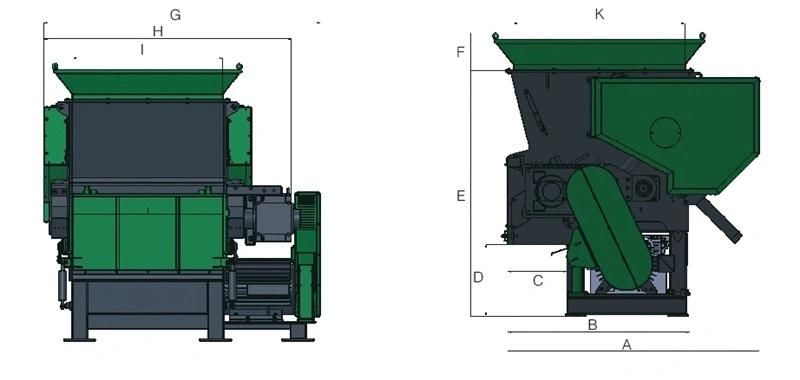

ItemUNIT SGS850 DGS1200 DGS1500 DGS2000 Cutting Chamber mm 840*1570 1120*1570 1400*1570 1960*1570 Rotor Diameter mm 457 457 457 457 Rotor Speed rpm 74 74 74 74 Motor Power kw 37/45/55 55 75 2*55/2*75 Rotor Knives pcs 60 81 102 144 Stator Knives pcs 2*3 2*4 2*5 2*7 Hydraulic Ram Power kw 3.75 5.6 5.6 5.6 Screen Size mm 40-100 40-100 40-100 40-100 Shredding Chamber Size mm 800*730 800*1000 800*1290 800*1860 Dimensions A mm 2300 2300 2300 2300 B mm 1650 1650 1650 1650 C mm 540 540 540 540 D mm 660 660 660 660 E mm 2250 2250 2250 2250 F mm 250 250 250 250 G mm 2000 2280 2600 3720

Layout

Features

Options

Applitions

Certificates

All of our shredders and granulators have been approved CE certification.

Factory

Since its foundation DGM Recycling Systems have been at the forefront of innovation and technology in the development of cost effective and reliable recycling solutions. As a wholly owned subsidiary of Miracle Automation Engineering Group, a pioneer in automation systems for the automotive and material handling industries, DGM continues to strive for excellence in the field of size reduction and recycling.

Suppliers

Packaging & Loading

1. Several layers of plastic wrapping film and cardboard to protect metal recycling machine from dust and moisture.

2. Plastic packing strap belt to fasten wrapping film and machines, also to fix machines in containers.

3. Wooden case is used as the outside package and spare parts by LCL, air or international express.

4. Excellant logistic team to guarantee the shredder and granulators machines to be safely shipped to customer appointed loaction.

5. If you have any other request for the packaging or loading, we will try our best to meet your demands.

FAQ

Q1: Are you a trading company or a factory ?

DGM is a factory with 10 years experience in machinery manufacturing, and 20 years experience in German technology.

Q2: Will you provide pre-sale services?

DGM consists of experienced specialists, we will offer a suitable solution according client's requirement in time.

Q3: Is your after-sales service excellent?

At DGM we have a highly trained team of service personnel to handle all manner of customer service enquiries. Whether it is replacement parts, technical assistance, or just general operation advice we offer our customers genuine 24/7 support and after sale service.

Q4: Where is your factory?

Address: No.1.Fengqi Road, Huishan District , Wuxi City, Jiangsu Province, China

Q5: What is your contact informatoin?

Fax: +86 510 8357 0210

Telephone: +86 510 8357 2002

Mobile : +86 18762812155

Q6: Could we visit your factory and test the machine?

We warmly welcome you to visit our factory anytime,and we are very glad to test our machine with your raw material.

Layout

Features

- Large diameter flat rotor

- Machined pocket knife holders

- Optional hard facing - Concave ground square knives

- Robust ram construction

- Heavy duty guide bearings

- Universal couplings

- Low speed, high torque geared drive

- Reduced footprint (compared to horizontal pusher designs)

- Powerful hydraulic swing type ram

- Bolt in drive shafts

- Oil cooling on ram and gearbox

- Two speed hydraulic system

- Multiple rotor designs

- Ram comb plate

- Amp meter control

Options

- Hydraulic screen cradle

- Gearbox with shrink disc

- Rotor cooling

- Pipe spacer

- Touch screen PLC Hopper mounted viewing mirror

- Increased motor drive

- Hydraulic drive

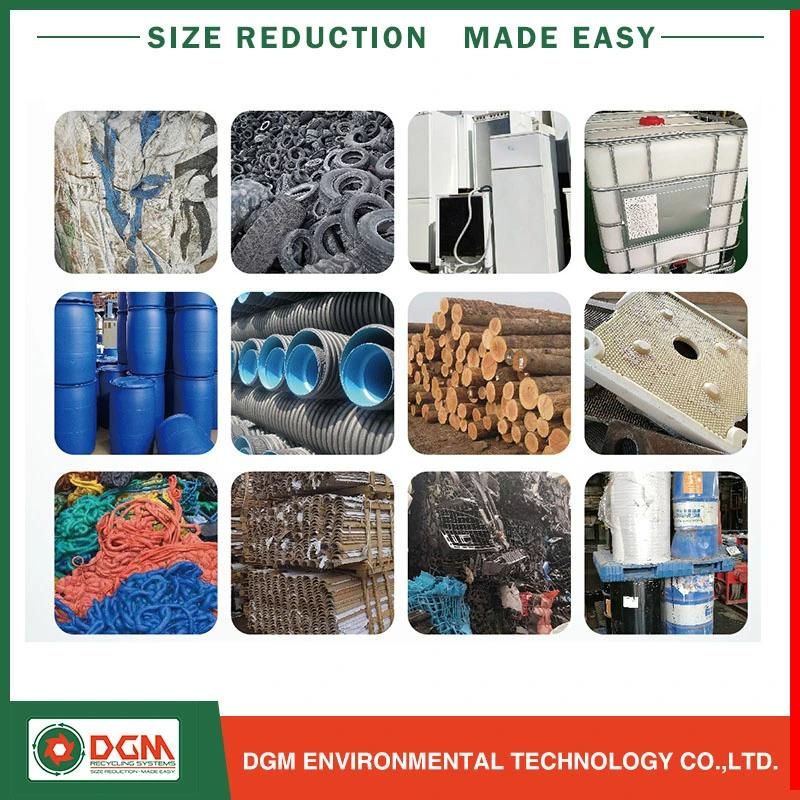

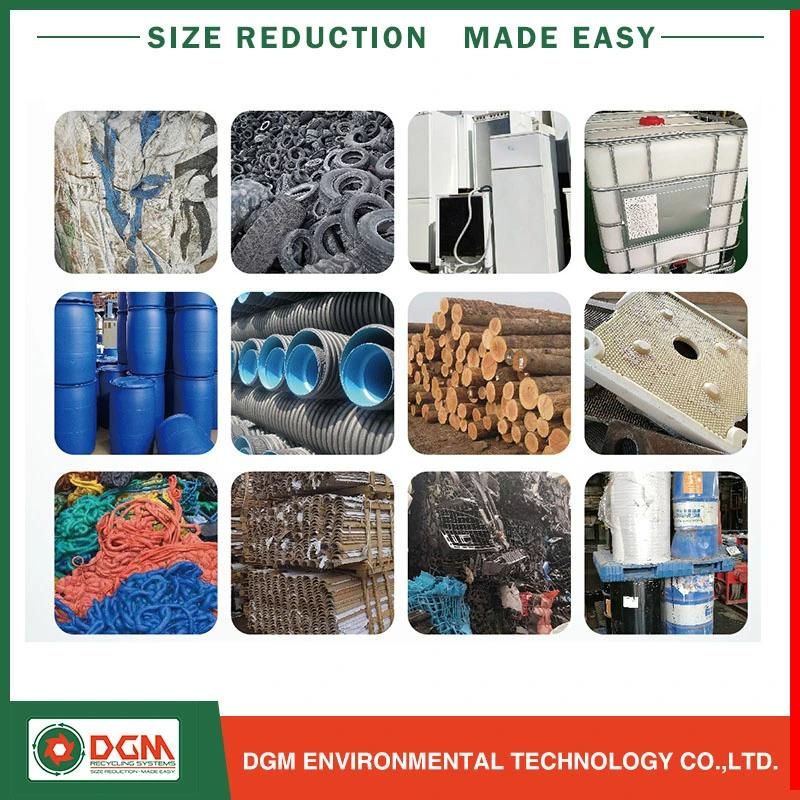

Applitions

- PLASTICS

- RUBBER

- WOOD

- BIOMASS

- PAPER

- ALTERNATIVE FUELS (RDF/SRF)

- DOMESTIC & COMMERCIAL WASTE

Certificates

All of our shredders and granulators have been approved CE certification.

Factory

Since its foundation DGM Recycling Systems have been at the forefront of innovation and technology in the development of cost effective and reliable recycling solutions. As a wholly owned subsidiary of Miracle Automation Engineering Group, a pioneer in automation systems for the automotive and material handling industries, DGM continues to strive for excellence in the field of size reduction and recycling.

Suppliers

Packaging & Loading

1. Several layers of plastic wrapping film and cardboard to protect metal recycling machine from dust and moisture.

2. Plastic packing strap belt to fasten wrapping film and machines, also to fix machines in containers.

3. Wooden case is used as the outside package and spare parts by LCL, air or international express.

4. Excellant logistic team to guarantee the shredder and granulators machines to be safely shipped to customer appointed loaction.

5. If you have any other request for the packaging or loading, we will try our best to meet your demands.

FAQ

Q1: Are you a trading company or a factory ?

DGM is a factory with 10 years experience in machinery manufacturing, and 20 years experience in German technology.

Q2: Will you provide pre-sale services?

DGM consists of experienced specialists, we will offer a suitable solution according client's requirement in time.

Q3: Is your after-sales service excellent?

At DGM we have a highly trained team of service personnel to handle all manner of customer service enquiries. Whether it is replacement parts, technical assistance, or just general operation advice we offer our customers genuine 24/7 support and after sale service.

We have an international network which ensures wherever you are in the world you receive localized high level support.

Our technical team has decades of experience in the field of size reduction and recycling and we are on hand to offer assistance in installation, commissioning, staff training and general technical assistance.

Q4: Where is your factory?

Address: No.1.Fengqi Road, Huishan District , Wuxi City, Jiangsu Province, China

Q5: What is your contact informatoin?

Fax: +86 510 8357 0210

Telephone: +86 510 8357 2002

Mobile : +86 18762812155

Q6: Could we visit your factory and test the machine?

We warmly welcome you to visit our factory anytime,and we are very glad to test our machine with your raw material.