Barrel Heater Jacket Used on Injection Molding Machine

DongGuan RedsAnt Energy Saver Limited- Certification:Reach & RoHS

- Insulation Material:Fiberglass & Aerogel

- Energy Saving:Save The Electric Energy 25%-45% at The Electric H

- High Temperature Resistance:750 Degrees

- Product Certification:Reach & RoHS

- Product Type:Thermal Insulation Product

Base Info

- Style:Sectional Type Installation

- Advantage:Tailor Made for Your Machine Size

- Feature:High Temperature Environmental Friendly

- Factory:Redsant Energy Saver Ltd.

- Transport Package:Standard Packing

- Specification:tailor made

- Trademark:RedsAnt

- Origin:China

- Production Capacity:10000 Sets,Month

Description

Basic Info.

Style Sectional Type Installation Advantage Tailor Made for Your Machine Size Feature High Temperature Environmental Friendly Factory Redsant Energy Saver Ltd. Transport Package Standard Packing Specification tailor made Trademark RedsAnt Origin China Production Capacity 10000 Sets/MonthProduct Description

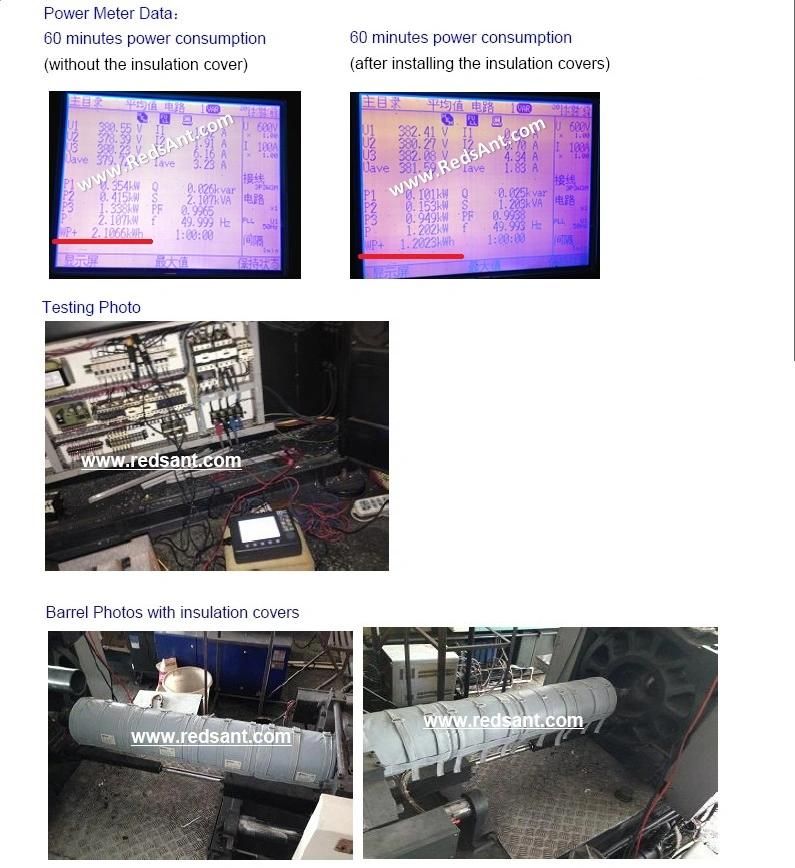

Barrel heater jackets offer excellent insulation benefits for the barrels of injection molding machines, blow moulders, extruders, extruder heads and lip dies, etc.This specialist insulation product can offer superb savings of up to 45% on barrel heating and is manufactured with the support of over 10 years of experience, so quality is guaranteed.

Product features:

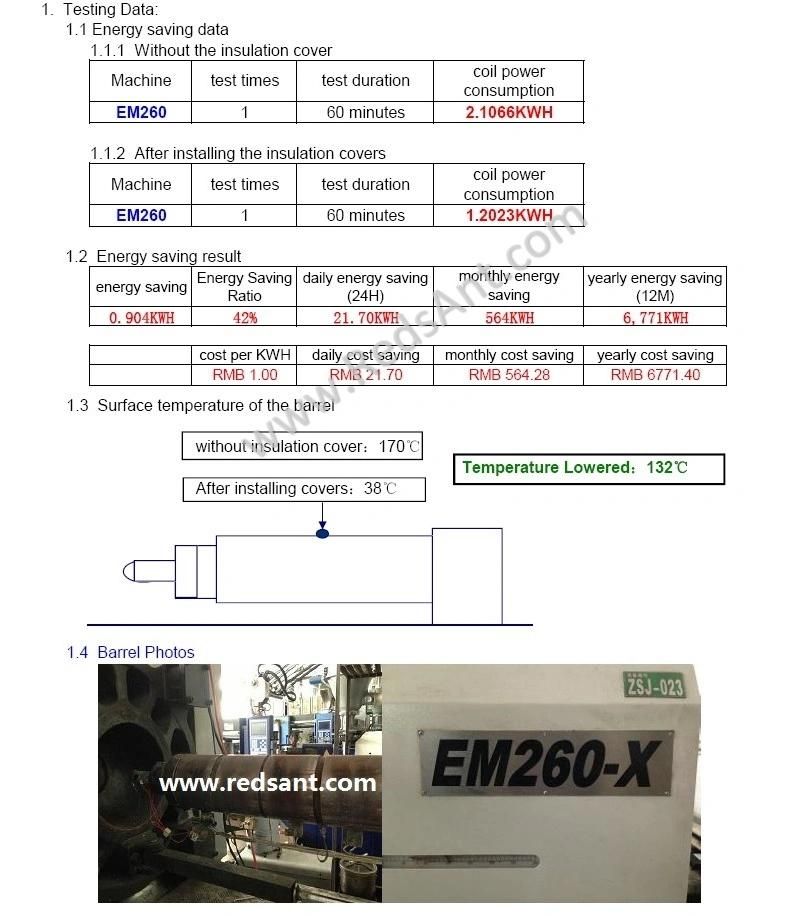

1. Barrel blankets will save the electric energy 25%-45% at the electric heating coil.

2. Improve the high precision injection quality by isolating the affects from environment temperature change and the wind influence. It has the function of temperature stabilization.

3. Sew by imported high temperature environmental friendly material, not the asbestos insulation materials.

4. Easy to disassembly and maintenance, reusable and long service life.

5. Products has passed the European Reach and RoHs environmental certification, products do not contain any toxic chemical composition of green environmental protection product.

6. Reduce the temperature of injection workshops. Improve the employees working environment.

7. Six months ROI (return-on-investment) with higher returns.

Energy saving report sample:

More:

More product information, please visit the company website in English version.

http://redsant.en.made-in-china.com