Customized PVC/UPVC Pipe Making Machine Extrusion Line

QINGDAO TRUSTY PLASTIC MACHINERY CO., LTD.- Warranty:14 Months

- Product Type:PVC Pipe

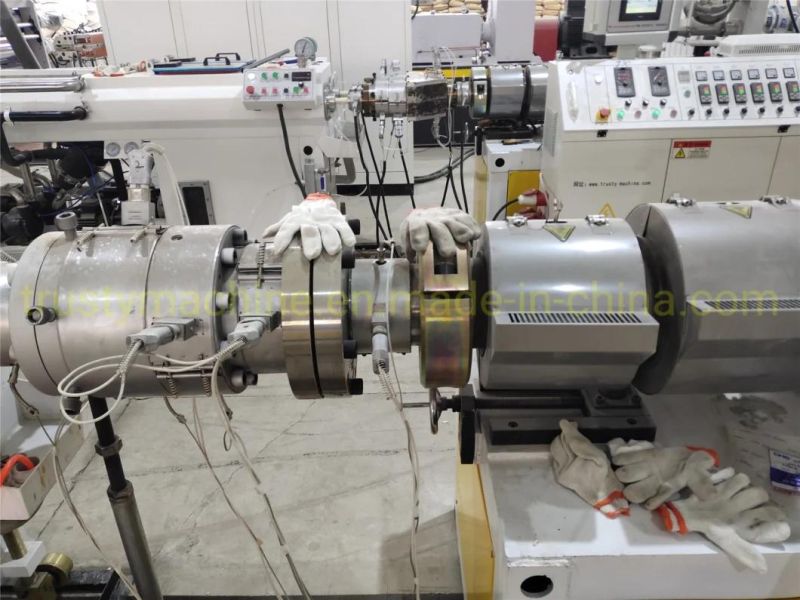

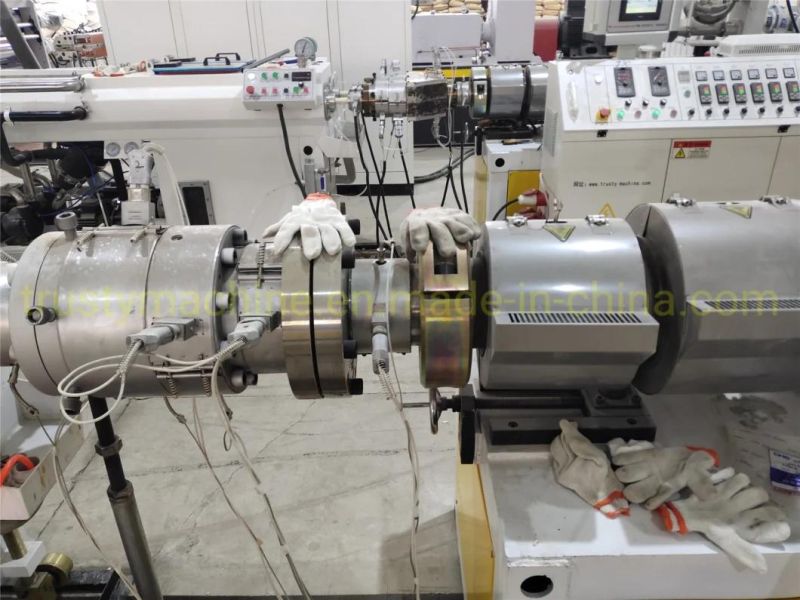

- Screw No.:Double-screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE

Base Info

- Model NO.:SJSZ-51,105 SJSZ-65,132 SJSZ-80,156

- Customized:Customized

- Condition:New

- After-sales Service:Oversea Installation&Debugging

- Contactor:Siemens

- Relay:Omron

- Inverter:ABB

- Motor:Simens

- Control System:Siemens PLC Control

- Assembly Structure:Separate Type Extrude

- Screw:Twin-Screw

- Screw Channel Structure:Deep Screw

- Temperature Controller:Omron

- Engagement System:Full Intermeshing

- Transport Package:Wooden Packing

- Specification:Customized

- Trademark:TRUSTY

- Origin:Qingdao

- HS Code:84772090

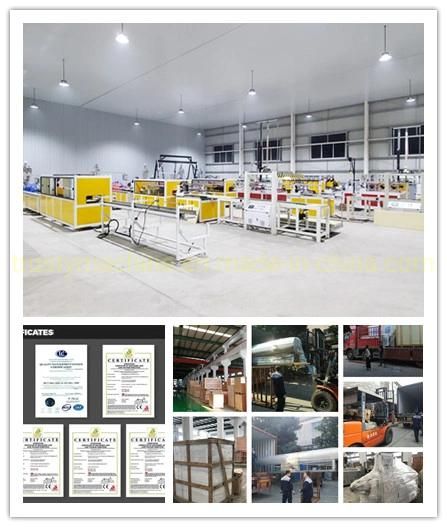

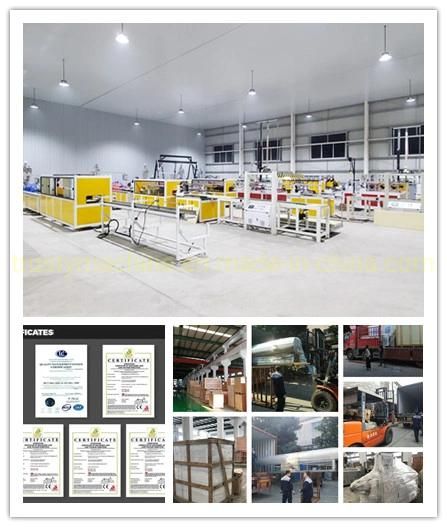

- Production Capacity:30 Sets,Month

Description

PVC pipe extrusion machine has features of low energy consumption, high output, stable running etc.

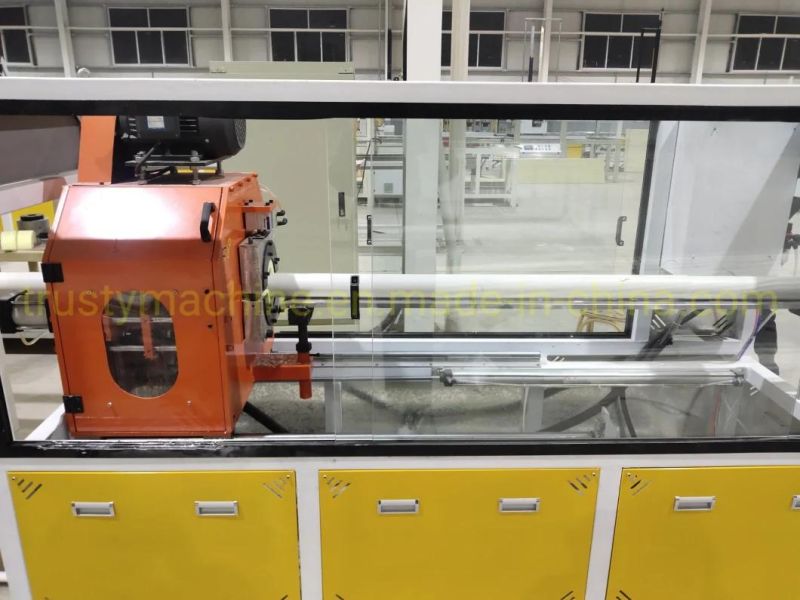

The standard PVC pipe extrusion machine include: material feeder, SJSZ series conic twin screw extruder, mould, vacuum calibration tank, spray cooling tank, haul-off, cutter, stacker. It is mainly used in producing various diameters and wall-thickness of PVC pipes for agriculture and constructional plumbing, electrical conduit etc.

It is mainly used in producing various diameters and wall-thickness of PVC pipes for agriculture and constructional plumbing, electrical conduit etc.

2. Machine List

Extruder

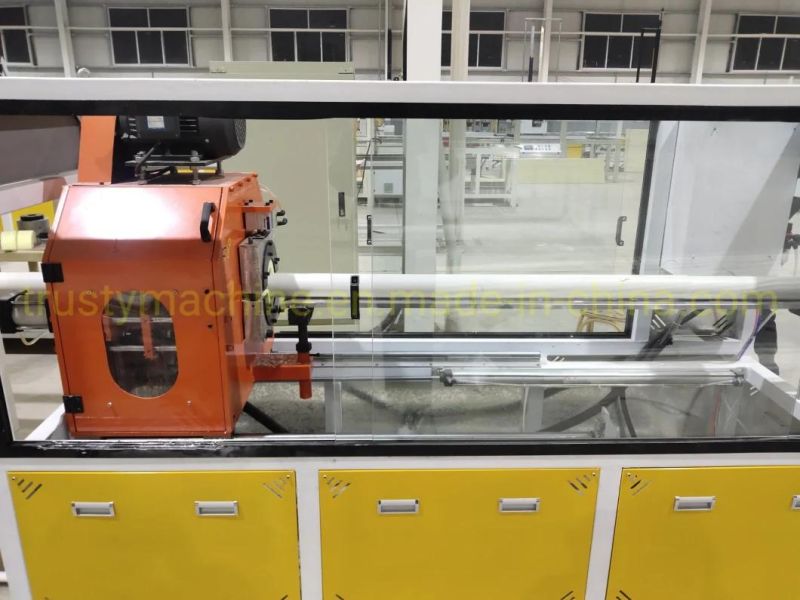

Mould Vacuum Table

Haul Off Cutter

Stacker

3. Production Flow

Our company's main products are: PVC door and window profile production line, WPC wood-plastic profile production line, PVC wall panel production line, PVC/PE/PPR pipe production line, PVC/WPC crust foam board production line, PE/PP/PC hollow sheet production line, PVC roof tile production line and PET packing belt production line, etc. According to customers' needs, to achieve diversified processing customization.

Over the years, the company has always adhered to the tenet of "honesty for basis, quality for living, innovation as the theme, and development as the focus", abide by the quality commitment to users, and won the trust of customers.

8. After Sales Service

9. FAQ

1.WHY CHOOSE US

We are the Professional manufacturer to develop the plastic extrusion machines in Qingdao. Machine quality and customer satisfaction is our pursuit.Be sure we have the strength to provide you with quality machines and perfect service.

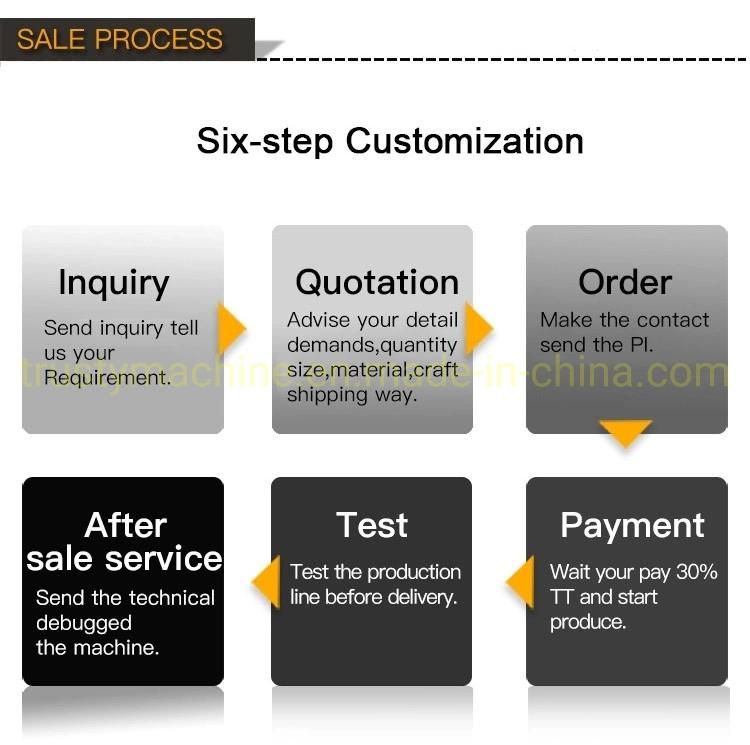

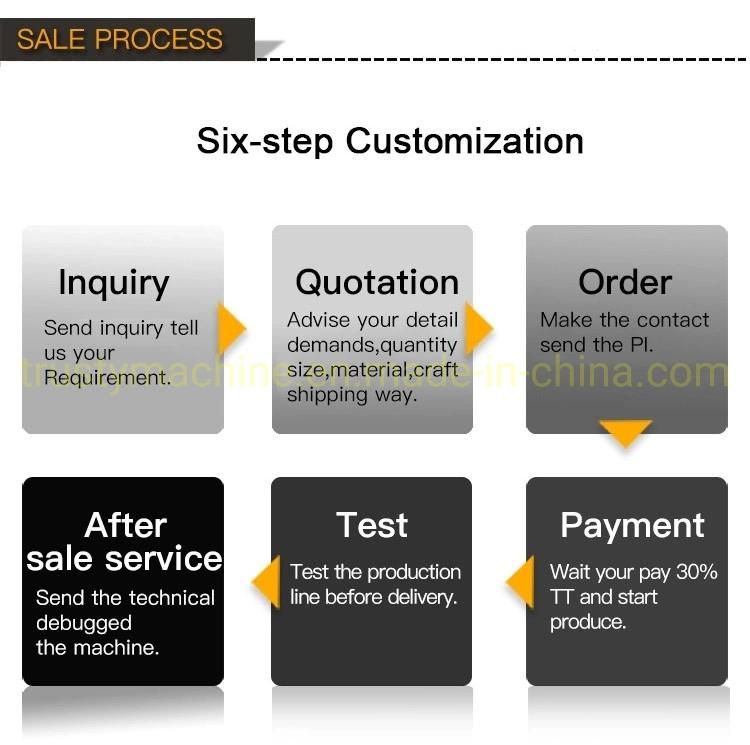

2.WHAT SERVICES DO WE OFFER?

Pre-sale communication → Design proposal, signature confirmation→

Customized production→ Test machine before shipment →Package &

delivery→ Engineer installation→Training operator → Technical support

3.PAYMENT TERMS:

30% of total amount should be paid by T/T as down payment ,the balance (70% of total amount) should be paid before delivery by T/T or irrevocable L/C by payment(at sight).

4.DELIVERY CONDITIONS:

4.1 Delivery condition: FOB Qingdao port or CIF destination Port.

4.2 Delivery terms: Within 30-60 working days after receipt of advanced payment, the seller should inform the buyer to do inspection,the seller should finish packing of goods and ready for shipment within 15 working days after the seller receipt the full payment.

5.WARRANTY TERMS

5.1 Warranty period: 12 months, starting from the machine receipt in customer's warehouse

5.2 Seller shall grant: services and spare parts, free-of-charge service throughout the entire equipment during warranty period.

5.3 long life service: the seller should provide long life service for the sold goods, the buyer pay for needed spare parts after the 12months warranty terms.

6.INSPECTION

When the machine finished, the seller should inform the buyer to do inspection before shipment, the seller guaranty good performance of all the sold goods.the seller undertake the material cost for the machine inspection in seller's factory. the buyer should come to seller's factory to do the inspection work, or the buyer could entrust any third party to come to seller's factory to do the inspection work.

7.INSTALLATION AND EQUIPMENT COMMISSIONING:

if the buyer requires, the seller should send technician team to buyer's factory for installation and testing the whole line, and the buyer should undertake the whole food/place and round tickets (airplane, food, hotel, and so on), and pay salary to engineer for 100 usd/day/engineer.

The standard PVC pipe extrusion machine include: material feeder, SJSZ series conic twin screw extruder, mould, vacuum calibration tank, spray cooling tank, haul-off, cutter, stacker.

It is mainly used in producing various diameters and wall-thickness of PVC pipes for agriculture and constructional plumbing, electrical conduit etc.

It is mainly used in producing various diameters and wall-thickness of PVC pipes for agriculture and constructional plumbing, electrical conduit etc.2. Machine List

3. Production Flow

Our company's main products are: PVC door and window profile production line, WPC wood-plastic profile production line, PVC wall panel production line, PVC/PE/PPR pipe production line, PVC/WPC crust foam board production line, PE/PP/PC hollow sheet production line, PVC roof tile production line and PET packing belt production line, etc. According to customers' needs, to achieve diversified processing customization.

Over the years, the company has always adhered to the tenet of "honesty for basis, quality for living, innovation as the theme, and development as the focus", abide by the quality commitment to users, and won the trust of customers.

8. After Sales Service

9. FAQ

1.WHY CHOOSE US

We are the Professional manufacturer to develop the plastic extrusion machines in Qingdao. Machine quality and customer satisfaction is our pursuit.Be sure we have the strength to provide you with quality machines and perfect service.

2.WHAT SERVICES DO WE OFFER?

Pre-sale communication → Design proposal, signature confirmation→

Customized production→ Test machine before shipment →Package &

delivery→ Engineer installation→Training operator → Technical support

3.PAYMENT TERMS:

30% of total amount should be paid by T/T as down payment ,the balance (70% of total amount) should be paid before delivery by T/T or irrevocable L/C by payment(at sight).

4.DELIVERY CONDITIONS:

4.1 Delivery condition: FOB Qingdao port or CIF destination Port.

4.2 Delivery terms: Within 30-60 working days after receipt of advanced payment, the seller should inform the buyer to do inspection,the seller should finish packing of goods and ready for shipment within 15 working days after the seller receipt the full payment.

5.WARRANTY TERMS

5.1 Warranty period: 12 months, starting from the machine receipt in customer's warehouse

5.2 Seller shall grant: services and spare parts, free-of-charge service throughout the entire equipment during warranty period.

5.3 long life service: the seller should provide long life service for the sold goods, the buyer pay for needed spare parts after the 12months warranty terms.

6.INSPECTION

When the machine finished, the seller should inform the buyer to do inspection before shipment, the seller guaranty good performance of all the sold goods.the seller undertake the material cost for the machine inspection in seller's factory. the buyer should come to seller's factory to do the inspection work, or the buyer could entrust any third party to come to seller's factory to do the inspection work.

7.INSTALLATION AND EQUIPMENT COMMISSIONING:

if the buyer requires, the seller should send technician team to buyer's factory for installation and testing the whole line, and the buyer should undertake the whole food/place and round tickets (airplane, food, hotel, and so on), and pay salary to engineer for 100 usd/day/engineer.