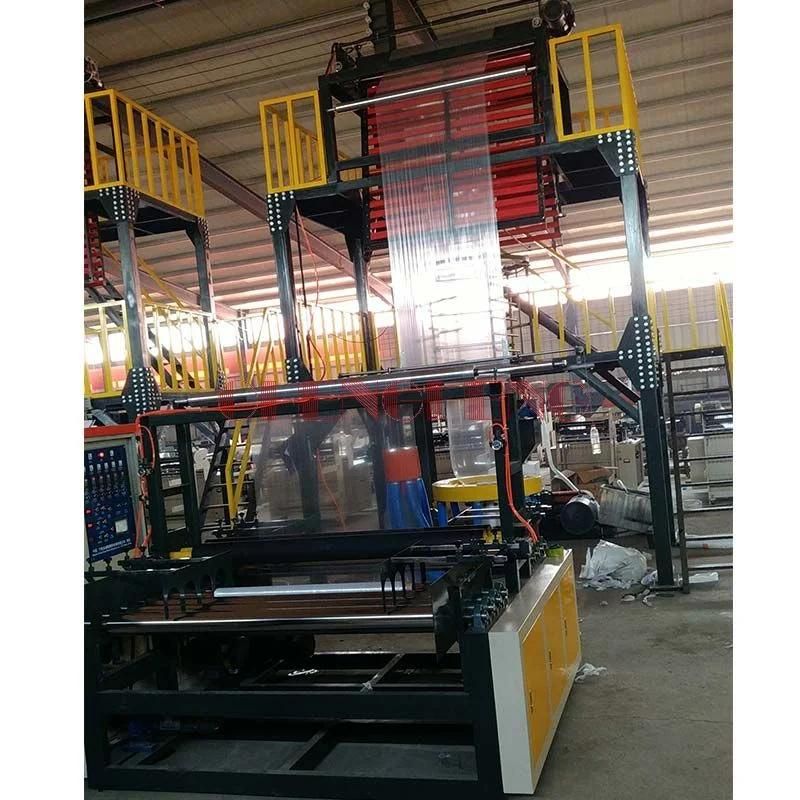

Chsj-Mf HDPE/LDPE/BOPP Mulch Film Blown Machine

HEBEI CHENGHENG PLASTIC MACHINERY TECHNOLOGY CO., LTD.- Type:PE Film Blowing Machine

- Raw Material:BOPP,HDPE,LDPE,Llpe

- Maximum Folding Width of Film:600mm

- Screw Diameter:45mm

- Automation:Automatic

- Computerized:Computerized

Base Info

- Machine Weight:2.8t

- Certification:CE, ISO9001:2008

- Width of The Film:200-600mm

- Name:ABA Film Co-Extrusion Blowing Machine

- The Max Output:85kg,H

- Power Consumption:25kg,H

- Quality Guarantee:5 Years

- Transport Package:to Be Packed in Wooden Box

- Specification:6.8*4*7.5m

- Trademark:CHENGHENG

- Origin:China

- HS Code:8477300000

- Production Capacity:200 Sets,Year

Description

Basic Info.

Machine Weight 2.8t Certification CE, ISO9001:2008 Width of The Film 200-600mm Name ABA Film Co-Extrusion Blowing Machine The Max Output 85kg/H Power Consumption 25kg/H Quality Guarantee 5 Years Transport Package to Be Packed in Wooden Box Specification 6.8*4*7.5m Trademark CHENGHENG Origin China HS Code 8477300000 Production Capacity 200 Sets/YearProduct Description

We are specialized in producing PE/PP film-making and film printing machines in plasticindustry, Having experience of more than 20 year, we provided to customer our good quality

machinery with 5-year- guarantee.

CHSJ-MF mulch blown film machine

| Model | MF-50/1300 MF-60/1600 MF-75/1800 |

| Film width (mm) | 300-1200mm 500-1500mm 500-1700mm |

| Film thickness | 0.006-0.08mm |

| max output | 55kg/h 75kg/h 85kg/h According to different width,thickness of film, die size and raw material characteristics to change |

| Raw material | HDPE/LDPE/LLDPE |

| Diameter of screw | Φ50 Φ60 Φ75 SACM 645 ,bimetallic ,five years guarantee |

| L/D ratio of screw | 30/1 |

| Main motor | 18.5kw 30kw 37kw 100% Original three-phase variable frequency motor Equipped with inverter control |

| Take up roller(mm) | 1300mm 1600mm 1800mm |

| Weight | 2800kg 3500kg 4200kg |

| Machine size | 6*3.6*5.8 6.5*4*6.2 6.5*4.2*7.5 |

Optional device:

Automatic Hopper Loader

Film Surface Treater

Rotary Die

Oscillating Take Up Unit

Two Stations Surface Winder

Chiller

Heat Slitting Device

Gravimetric Dosing Unit

IBC(Internal Bubble Cooling Computer Control System)

EPC(Edge Position Control)

Electronic Tension Control

Manual mechanics screen changer

Edge material recycling machine

Product feature

1.The whole machine is square structure

2.Traction inverter control, host frequency conversion control, (optional fan frequency control, winding frequency control) 100% inverter motor + frequency converter control

3. Full enclosed overtemperature cooling device

4. Brand Industrial electricity

5. Lambdoidal board

6:Ceramic heater

You are welcome to raise any suggestions and questions for more details by sending us mails

or posts at any time.