Twin Screw Extruder for Engineering Plastic/ PP PE Compounding /Masterbatch Pelletizing ...

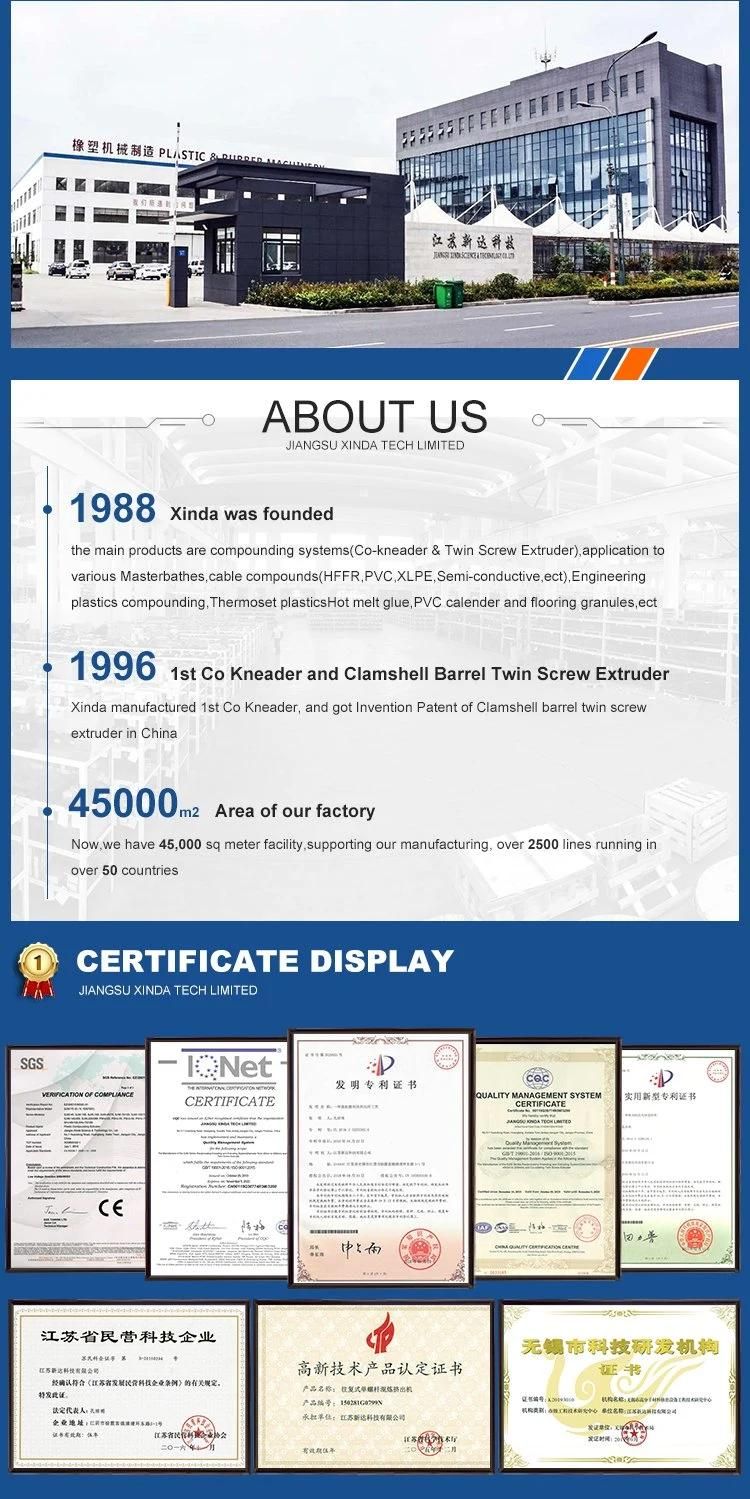

Jiangsu Xinda Tech Limited- Warranty:1 Year

- Raw Material:Mixing

- Screw:Double-Screw

- Inverter:Inverter

- Electromagnetic Heater:Electromagnetic Heater

- Automation:Automatic

Base Info

- Model NO.:PSHJ-50

- Computerized:Computerized

- Customized:Customized

- Certification:CE, ISO9001:2008, QS, UL

- Condition:New

- Capacity:80-200kg,H

- Applications:All Kinds of Polymer Mixing

- Electric Brands:Siemens , Schneider

- Control:PLC + Touch Screen

- Extruder Weight:6000kg

- Transport Package:Pallet and Wooden Box

- Trademark:XINDA

- Origin:China

- HS Code:84772010

- Production Capacity:200sets,Year

Description

XINDA Clamshell Barrel Co-Rotating twin screw extruder for Master batch Compounding

- Masterbatch is a concentrated mixture of pigments and/or additives encapsulated during a heat process into a carrier resin which is then cooled and cut into a granular shape.

- Xinda Co-rotating twin screw extruder will melt, mix, kneading the dry blend of resin carrier and pigments and additives and pelletize into perfece master batch pellets by water strand pelletizing.

- Xinda Clamshell barrel Co-rotating twin screw extruder can be opened for cleaning, checking, and maintenance. It is ideal for color changing for Master batch compounding.

XINDA PSHJ Clamshell Barrel Co-rotating Twin Screw Extruder for Master batch !!!

The barrel can be opened in minutes. This makes product changeover, maintenance and research fast and easy. Both screws and barrels are designed using the building block principle. The screw configuration, barrel setup, feeding and venting, screen changing, way of pelletizing and process requirements, in consideration of the machine's versatility in other general applications.

High filled master batch with underwater pelletizing system:

1, Underwater pelletizing is most applicable for many kinds of formula

2, Underwater pelletizing system provides more uniform and good-size of pellets

3, Underwater pelletizing system provides a stable running