Factory Price 800mm-1000mm Width PVC ASA Glazed Roof Tile Production Line Twin Screw ...

Qingdao Hanhai Plastic Machinery Co., Ltd.- After-sales Service:Engineers Available to Service Machinery Overseas

- Warranty:1 Year

- Type:Profile Extruder

- Plastic Processed:PVC

- Product Type:Profile Extrusion Molding Machine

- Feeding Mode:Multiple Feed

Base Info

- Model NO.:SJSZ55, SJSZ65, SJSZ80, SJSZ92, SJSZ120

- Assembly Structure:Separate Type Extruder

- Screw:Twin-Screw

- Engagement System:Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Motor:Simens Beide

- PLC:Simens

- Capacity:280kg,H

- Speed of PVC Corrugated Sheet Line:1m-3m Per Minute

- Total Power:150kw

- Transport:by Sea or Train

- Total Weight:10ton-15ton

- Other Name:PVC Corrugated Sheet Line

- Other Name1:PVC Trapezoid Sheet Production Line

- Other Name2:PVC Trapezoid Sheet Making Machine

- Other Name 3:PVC Wave Sheet Making Machine

- Other Name4:PVC Trapezoid Sheet Extrusion Line

- Other Name5:PVC Trapezoid Sheet Extrusion Machine

- Product Model:Sjz51,105,Sjz65,132,Sjz80,156,Sjz92,188

- Model:Sj80,156,Sj92,188

- Transport Package:Machine Covered by Plastic Film

- Specification:900mm

- Trademark:Hanhai

- Origin:Qingdao, China

- HS Code:84772090

- Production Capacity:30-50 Sets Per Year

Description

Product advantages | Disadvantages |

High strength, sound proof and damp proof, long service life | Hard shaping. long testing time. high requirements on mould |

Light specific gravity. good toughness, sound proof and damp proof, etc. | High requirements on formula, high requirements on technique |

Simple processing, low investment | High specific gravity, high maintenance cost |

2.PVC Corrugated hollow sheet making machine Mold(1) Material: 40GR(2) Size: Customized

3.PVC Corrugated hollow sheet making machine Forming machine Bracket(1) Stainless steel clamping platform(2) Material: Stainless steel(3) Diameter: Customized

4.PVC Corrugated hollow sheet making machine haul-off machine(1) Driving motor power: 11 kw(2) Drawing speed: 0.2~5 m/min(3) Haul-off method: 6 caterpillars

5.PVC Corrugated hollow sheet making machine cutting machine(1) Method: Saw cutting (2) Cutting scope: Customized(3)Power :3KW

6.PVC Corrugated hollow sheet making machine Stacker(1) Length: 2.5 m(2) Width:1m

(3) Material: Stainless steel

PVC co-extruded foam insulation sound insulation tile

The latest composite co-extrusion technology is used to produce a new

generation of PVC sound insulation tiles.

The surface layer can be made of weather-resistant PVC modified material or ASA raw material,

the core layer has a foam density of 0.35-0.55g / cm3, super durable, heat preservation, environmental

protection and energy saving, asbestos-free, good heat insulation, acid and alkali corrosion resistance,

economical, The colorful and durable features are the choice of new-generation factory buildings (especially

electroplating plants, chemical plant buildings for tile replacement), warehouses, real estate, aisles, roofs,

carports and other engineering roofing building materials.

1) Excellent thermal insulation performance and stable chemical properties. The upper and lower layers are

modified upvc, and the middle layer is a polymer foam layer. UPVC insulation tiles and the use of core foaming

technology ensure that a porous structure is formed inside the product to effectively block the transmission of

heat insulation energy. The thermal conductivity of the insulation tile is 0.219W / mk, which is about 1/3 of the

earthen tile, 1/5 of the 10mm thick cement tile, and 1/2000 of the 0.5mm thick colored steel tile.

2) The core layer of the three-layer foam insulation tile is a porous material with porous ventilation properties.

When the sound of falling rain strikes the tile surface, the sound waves are transmitted to the porous material,

causing air vibration in the gap and friction with the porous wall. , Reflection, attenuates the sound energy and

produces a sound absorption effect, achieving the function of sound insulation.

3) UPVC insulation tiles are available in 4mm, 5mm, and 6mm thicknesses, with a wave pitch of 210mm and

a wave height of 27mm. The width is 835,940mm and the length can be customized.

4) Durable and resistant to acid, alkali, and corrosion, with a service life of more than 20 years under normal

outdoor conditions in the subtropics.

5) Good mechanical properties, high strength, good toughness! Adding various modification additives to the

materials of each layer of tile has changed the physical properties of PVC resin. The special production process

treatment greatly enhances the mechanical strength of the tile body while maintaining the good toughness of the

substrate of PVC resin , So that the thermal insulation tile itself has super strong bending strength, compressive

strength, bending strength and impact strength. On the basis of completely guaranteeing safe construction, it is

also safe to use even in coastal areas with many typhoons!

6) Good fire resistance, flame retardant B1 building materials, no worry about fire!

Advantages of three-layer co-extrusion foaming equipment:

1) Special screw structure design can meet the requirements of high foaming rate of core layer and high

weather resistance of surface layer

2) Special co-extrusion flow channel design, greatly reducing the requirements for foam mold removal

3) Professional design of molds and shaping molds, suitable for the requirements of high foam roof tiles

4) Formula and process guidance to help you master the new technology of PVC foam tile faster

5) Full service of engineers to speed up the timely delivery of your factory orders

Final product pictures:

You just tell me what machine you want,let us do the rest work:

1. Design and manufacture suitble machine for you.2. Before delivery, we will test the machine until you are completely satisfied. (You can come to

our factory to inspect the running production line.)

3. Delivery.

4. We will provide after-sales service:

(1) Field installation and commissioning;

(2) Field training your workers; (3) Field maintenance and repair service ;

(4) Free Spare Parts ;

(5) Video/Online technical support.

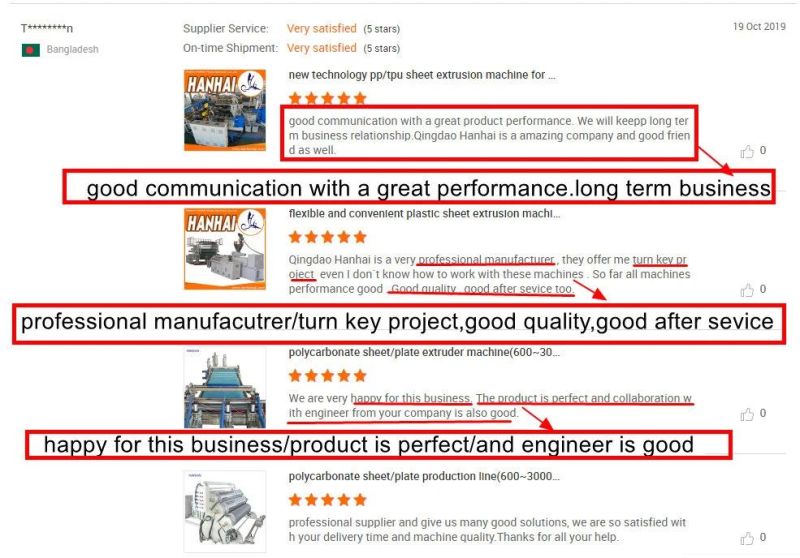

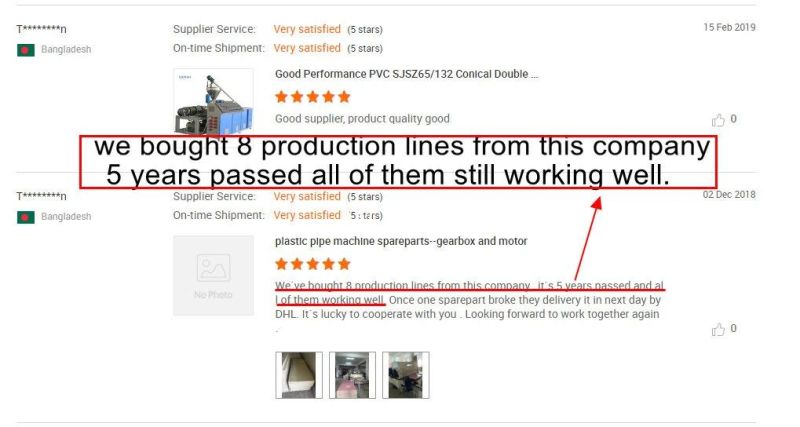

Reviews by customers:

FAQ:

1.Are you manufacturer or trading company?

We are manufacturer.

2.Why choose us?

We have 20 years experience for producing machine.We can arrange for you to visit our local customer's factory.

3.Delivery time: 20~30 days.

4.Payment terms:

30% of total amount should be paid by T/T as down payment, the balance (70% of total amount) should be paid

before delivery by T/T or irrevocable L/C(at sight).

5.Warranty: 1 year.

Feel free contact us at any time and most welcome to visit our factory!