Automatic Plastic Bottle Cap Wadding Lining Foil Inserting Machine

Ruian Furi Packaging Machinery Co., Ltd.- After-sales Service:Engineer Available for Oversee Machine Service

- Warranty:1 Year

- Product Type:Plastic Bottle

- Screw:Single-Screw

- Automation:Automatic

- Computerized:PLC

Base Info

- Model NO.:FRTB-SD3-C

- Certification:CE

- Customized:Customized

- Capacity:120-160pec,Min

- Voltage:220V

- Power:1.5kw

- Specification of Cap:φ20-50mm

- Quality Guarantee:1 Year

- After-Sale:Engineers Available to Service Machinery Overseas

- Liner Material:PE, Paper Board, Aluminum Foil

- Feeder Type:Hoister Feeder, Vibrator Feeder

- Electrical Control System:Variable Frequency Control

- Machine Material:Stainless Steel

- Transport Package:Wooden Box

- Specification:3000× 1000× 2200MM

- Trademark:FURI

- Origin:China

- HS Code:8422303090

- Production Capacity:10sets,Month

Description

1. Scope of Application:

1. Scope of Application:This machine is widely used in the industry of Bottle Cap, Liner, Medicine, Foodstuff, Household Chmeicals, Package, etc. It is an ideal inserting machine.

2. Technical Parameters

3. Structure of equipment:

4. Features:

1) This machine replaces the handwork. It automatically inserts the liner into the bottle cap, and can raise work efficiency greatly.

2) Reasonable Liner Sealing, Fast speed, High efficiency, Safe and Sanitary product.

3) This machine is specially suitable for the occasion which has strict and severe sanitary requirements. It can avoid secondary pollution on the materials, and it can omit the sterilizing technics.

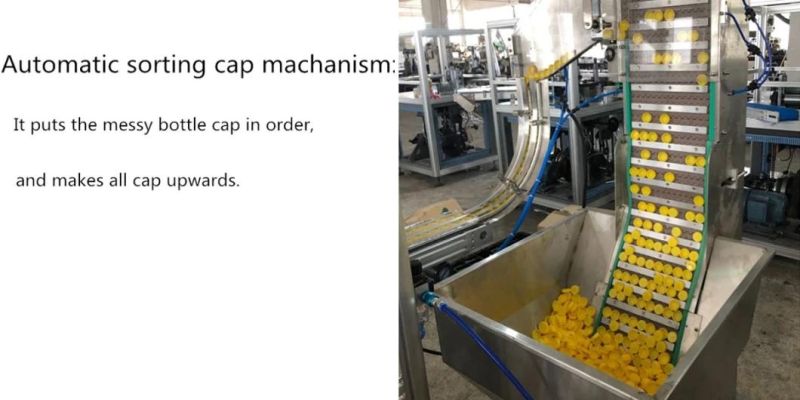

4) Sorting Cap System attaches the function of cap elimination, in order to make sure every finished bottle cap upward.

5) It has automatic counter inside, and can greatly raise the working efficiency afterwards.

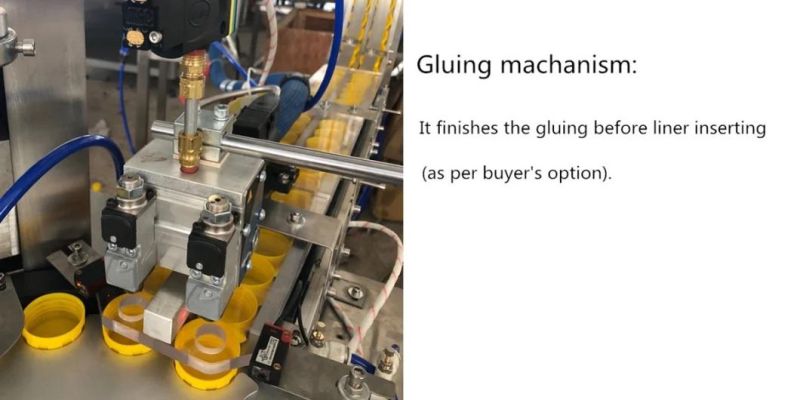

6) It delivers the bottle cap by driving convey with accurate position. This machanism can put the messy bottle caps in the vibrating loading tray in order, and load them into the guide rail. The turnplate positions the caps and then it delivers to glue caps one by one automatically. Finally it automatically delivers to the outleting dipper.

7) It adopts mechanical drive deliver position machanism to make the machine operate smoothly. It is suitable for various specifiations of bottle caps and aluminum foil.

8) It adopts PLC controller, and has the alarm while out of liner and bottle cap. The electric control system adopts frequency conversion techniques. It has the advantages of free setting, wide application, easy operation, stable working, convenient cleaning and maintenance, durable in use, etc.

9) Our fully automatic packing machine is in strict accordance with National GMP Standard and process requirements.

OUR FACTORY

MACHINE PACKAGE

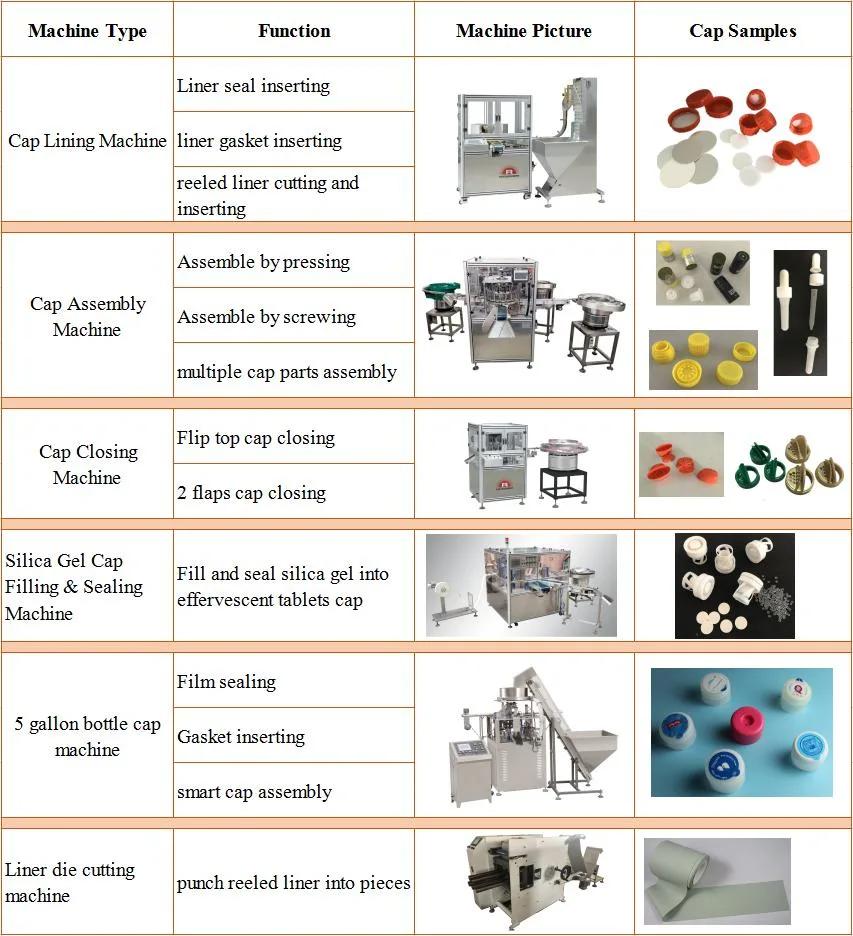

MACHINE PACKAGE We customize all kinds of non-standard bottle cap processing equipments:

We customize all kinds of non-standard bottle cap processing equipments:

More Details , Kindly contact us.

Attn:Becky Pan

Location: (Zhixin Industrial Zone)C-13-12, Ruian, Wenzhou City, Zhejiang Province

By Flight: Arrive at Wenzhou Airport

By Train: Arrive at Ruian Station