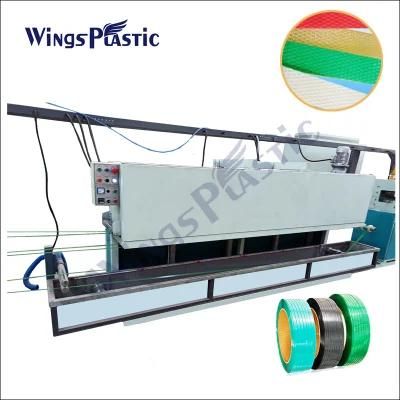

Germany Technology Pet Strap Manufacturing Machine Pet Packing Tape Production Line

Qingdao Wings Plastic Technology Co., Ltd.- Type:Filament Machine

- Plastic Processed:Pet

- Product Type:Extrusion Molding Machine

- Feeding Mode:One Feed

- Assembly Structure:Integral Type Extruder

- Screw:Single-Screw

Base Info

- Model NO.:SJ90,30

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Don′t Exhaust

- Automation:Automatic

- Computerized:Computerized

- Transport Package:Wood and Film

- Specification:90,30

- Trademark:Wings

- Origin:Qingdao

- HS Code:84772090

- Production Capacity:30 Lines Every Year

Description

Pre crystallization drying unit

Pre crystallization drying unitAs PET is easy to absorb moisture in the air, it must be fully dried. At the same time, in order to prevent bonding during drying, crystallization equipment needs to be configured

PP strap not need it.Single Screw Extruder

Always PET two straps extrusion needs 90/30 single screw extruder.

PP two straps extrusion needs 75/30 single screw extruder.

Special design screw structurer could extrude PET PP materials smoothl,it does not create excessive shear molecular structure, and ensures the strength of the packing belt

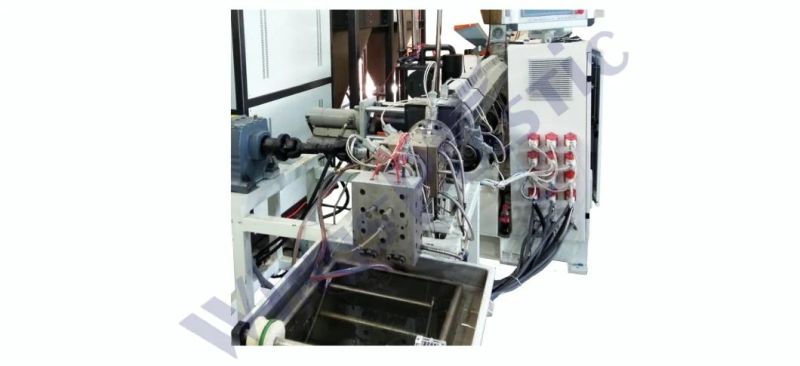

Filter, Melt Pumb, Exrusion Die Unit

Filter, Melt Pumb, Exrusion Die UnitIt is controlled by PLC pressure closed loop control system. The pressure sensor will transmit signals, and PLC is used to control the speed of melt pump and extruder, so as to stabilize the extrusion of PET or PP materialsWater tank with first haul off rollers

PET is Length 4000mm, PP 2000mm.

It is stainless steel materials.

The water is heated by water tank heating unit

The haul off rollers is five rollers, working to take PET or PP strap materials out of water tank

The stretching oven

The stretching ovenThe oven is heated by electric power. Heating air is spread evenly by fans.

In the oven, the PET and PP strap will be stretched first time.Stretching rollers.

This device is working for PET strap second time stretching.

PP strap not need stretching.

Embossing Roller

Embossing RollerThis 38Crmoal materials, high surface hardness rollers do embossingAnnealing oven and cooling tank

As PET and PP materials has high deformation prestress after stretching. It has to do annealing and water cooling to fix the size.

Three rollers puller

Three rollers pullerIt is working to take the materials out of annealing oven and cooling tank before windersAutomatic winder

The winder could be designed into servo motor unit, inverter motor unit and torque motor according PET or PP materials and with