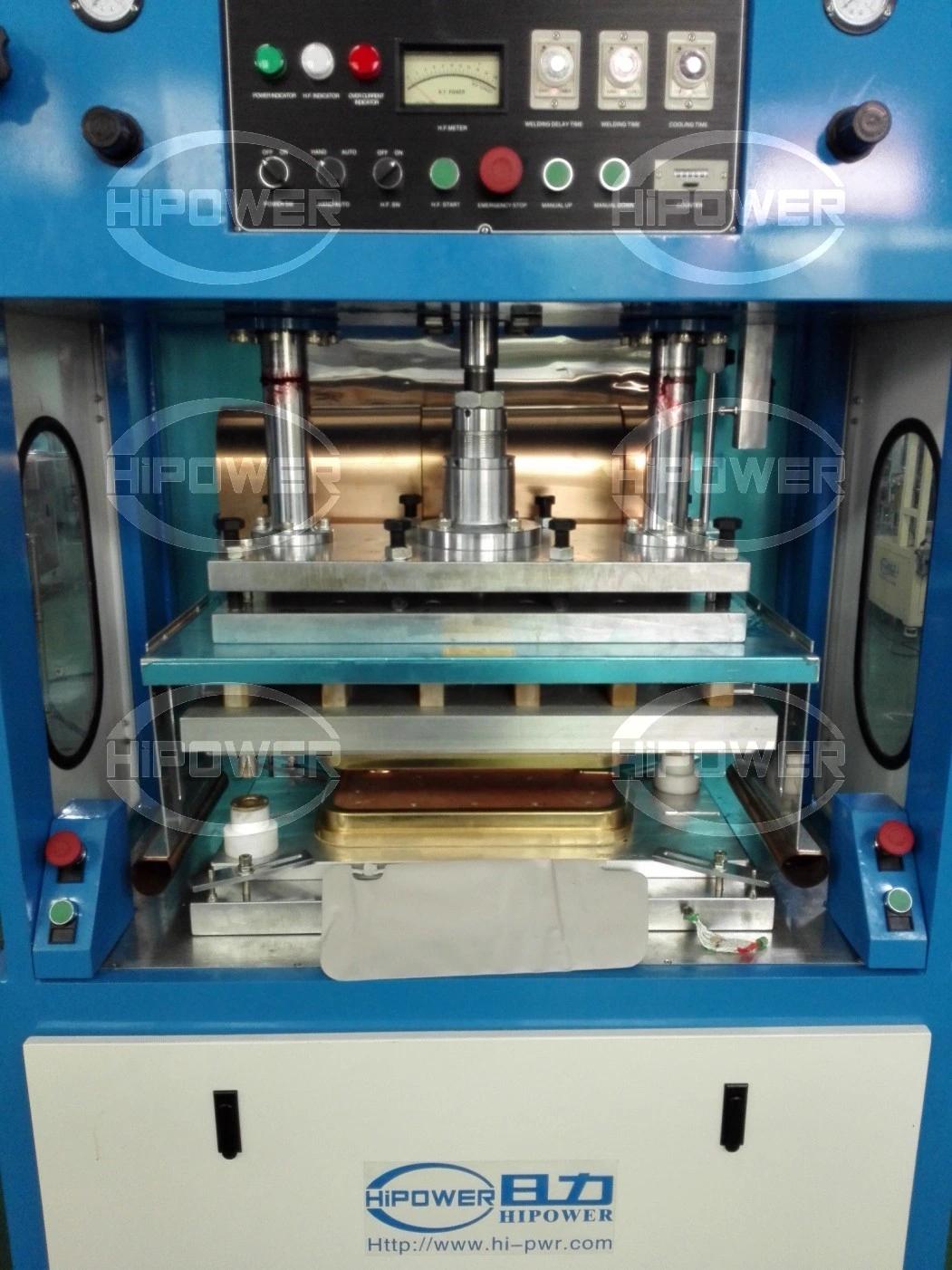

High Frequency PVC Plastic Welding Machine for Car Tent/Truck Cover (HR-10KWF)

Dongguan Hipower Ltd.- Color:Green or Customize

- Transport Package:Wooden Case for Export

- Specification:CE

- Trademark:HIPOWER

- Origin:Shenzhen

Base Info

- Model NO.:HR-10KWF

- HS Code:8515900090

- Production Capacity:500 PCS,Year

Description

Application:

Specialize for the plastic product with need to be welded material together and cut the extra edge out simultaneously.

This kind of machine can be also called as HFsimultaneous welding and cutting machine. Mainly apply for welding and cutting

APET, PETG, GAG, Double side clamshell, blister+cardboard, leather, OPP, PU and many other environment-friendly materials. Machine General Features:

Machine General Features:

1. Specialize for making sunvisor

2. Good for welding environmental production dress glue products like APET, PETG, GAG materials.

3. Can weld and trim simultaneously.

4. Esay to operate with pre-set function

5. Accurate-orientation, error+20um.

6. Cutting pressure can adjust from 100kg to 2ton

7. Firm in structure, stable and realible in output.

8. Adopting high sensitive anti-sparkle device NL5557 to avoid damaging the mould efficiency.

9. Operation mode: Pneumatic.

10. The size of active horn is adjustable for prefect welding.

380V 50/60Hz

Certifications

After Sales Service

a) Customer's site installation, training & maintenance available

b) 3 to 24 hours Online service by Email, Fax, Video Online for basic setup and repairs

c) 12 months warranty for machine, life-long tech. support

d) Recommend equipment of top choice based on your requirements for product;

e) Examining mold drawings on your behalf to confirm optimum structure size meeting the requested process;

f) Providing assistance in manufacturing and modifying tools;

g) Our engineering instruction will guarantee your productive manufacturing of top-quality products.

FAQQuestion 01: Are a trading company or Manufactuer?RE: Since 2000, we are the manufacturer in this filed;Our factory can design, develop and manufacture ODM and OEM equipments for clients all over the worlds.

Questions 02: What about Delivery Time:RE: 3 days for standard machine; and 15 to 35 days for custom machines

Questions 03: Payment Term:RE: We accept payment by T/T, L/C, West Union, Paypal.

Questions 04: How do I inspect your machine quality?RE: We always have real machines ready in stock, We shall meet you at airport, hotel, or railway station.

Questions 05: Is the machine easy to use and maintain in future?RE: Yes, it is; we shall provide instructional manual, videos and engineer support via email or video talk online.

Questions 06. How Do You Pack the machines

RE: Our machines will be packed into after treatment wood box

Questions 07. Does the machine power voltage meet buyers' factory power source?

RE:Frequency: 50 - 60HZ Phases: single phase / 3 phases ; Voltage: 110V / 220V / 380V/ 415V/ 440V / On request

Questions 9. Could you make die / mould for me, if I buy machine from you?

RE: We design and make moulds up to product sample or drawings, we charge the mould price at facory cost price.