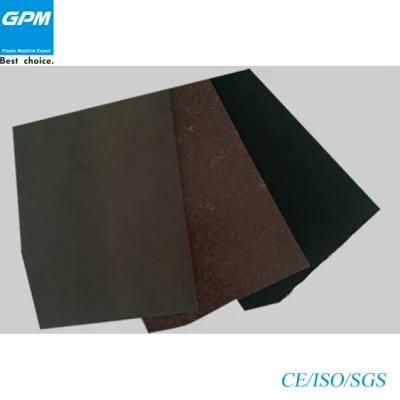

PP + Hemp Fibers or Wood Flour Film Sheet Extrusion Line

GPM Machinery (Shanghai) Co., Ltd.- Type:Sheet Extruder

- Plastic Processed:PP

- Product Type:Granulating Extruder

- Feeding Mode:One Feed

- Assembly Structure:Integral Type Extruder

- Screw:Twin-Screw

Base Info

- Model NO.:SJ

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Trade Assurance:20,0000 Dollars

- Material:PP,PVC

- Function:High Strength,Dimensional Stability

- Voltage:380V 50Hz 3phase (Customized)

- Transport Package:PE Film Packaging

- Specification:according to cutomer

- Trademark:GPM

- Origin:Shanghai, China

- HS Code:8477209000

- Production Capacity:500set,Year

Description

Basic Info.

Model NO. SJ Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Trade Assurance 20,0000 Dollars Material PP,PVC Function High Strength,Dimensional Stability Voltage 380V 50Hz 3phase (Customized) Transport Package PE Film Packaging Specification according to cutomer Trademark GPM Origin Shanghai, China HS Code 8477209000 Production Capacity 500set/YearProduct Description

Product ApplicationPP/PE WPC advantage of automotive interior panels:thermoplastic composite material compared to wood,plastic materials,taking into account the advantages of both,with a wet and dry strength uniform,high strength,dimensional stability,rolling resistance,easy to shape and other characteristics.

with a variety of fabrics(knitted,woven fabrics,leather,etc.)combined into a variety of specifications of automotive interior parts,can be widely used in passenger and cargo,car roof,door guard,luggage rack shelf,overhead tank side Wai and other interior products.Products made of light weight,high strength,good toughness,smooth surface,not easily deformed,easy assembly and so on.