High Output of PVC Foam Board Making Machinery

Qingdao Weier Plastic Machinery Co., Ltd.- Type:Sheet Extruder

- Plastic Processed:PVC

- Product Type:Extrusion Molding Machine

- Feeding Mode:Multiple Feed

- Assembly Structure:Separate Type Extruder

- Screw:Twin-Screw

Base Info

- Model NO.:80,156

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Non-Automatic

- Computerized:Computerized

- PVC Crust Foam Board Production Line/PLA:PVC Crust Foam Board Production Line,Plastic Machi

- Width:1220mm, 1580mm

- PVC Foam Board Production Line:Co-Extrision Machinery

- Transport Package:as The Requests

- Specification:CE, ISO, SGS, BV

- Trademark:WEIER

- Origin:Qingdao, China

- HS Code:84772090

- Production Capacity:10 Units Per Month

Description

Model

Extruder

Width

Thickness

Capacity

S1220

SJSZ80/156

1220mm

<25mm

350KG

S1830

SJSZ92/188

1830mm

<25mm

<800KG

Excellent Features of pvc crust foam board :

We did this machine for many times; and have this machine in stock for checking;

1>Strong and durable; Lightweight and easy to install; Not easy to scratch;

Will not rot, warp, delaminate, cup or twist;

2>Resistant to weather, shock and abrasion;

3>Salt water corrosion resistant;

Impervious to salts, insects and many chemicals, including some acids;

4>Doesn't mold; Can be worked just like wood;

Non-toxic; 100% recyclable; Fire-retardant (self-extinguishing);

5>Easy to clean; Virtually maintenance free;

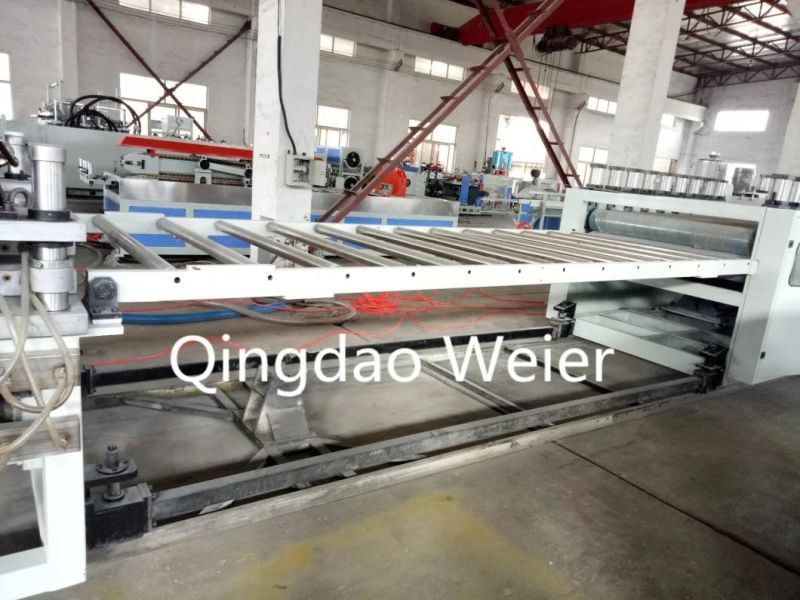

Machine line details:

1.SJSZ 80/156 Conical twin Screw Extruder

ABB frequency converter, SIEMENS contactor, OMRON Japan, Motor power:75KW

2.Calibration unit

calibration plate:1500mm×500mm 4 couples

3. Cooling tank and bracket

length:6000mm

trimming knife:3 sets

4. Haul-off unit

8 couples

cylinder clamping and loosening

5. Cutting unit

6. Stacker

7. Mould (T-Die )

We did this machine for many times; and have this machine in stock for checking;

Packaging & Delivery

1.The machine body is covered by waterproof film firstly, and then fixed on exported wooden

pallets with bolts and wires.

2.The electric controlling parts and spare parts are loaded separately in wooden box.

3.The auxiliary equipments are packaged in wooden box as well.

4.All wooden material is fumigation certificated and safe for exporting to all over the world.

wooden packaging is 49.5USD/m3.

Delivery Time

30 working days

Our Service

Pre-sale

We provide presales service in various forms, for example, making investment budget,

manufacturing planning, etc. so that customers make a reasonable plan with less cost.

Investment budgeting---We provide services of product profit analysis, recommendation of

machine and auxiliary equipment and relevant budgeting, human resources allocation and

budgeting.

Plant Planning---We provide the mounting dimension of the equipment base, design of equipment

layout, workshop ventilation, water transmission etc.

On-sale

Detailed design of workshop lay-out

Technological information of provided products

Schedule about design, manufacture and installation

Working & Producing process

Training courses for the technician team so that the installation is safe and standard

After-sale

For customers buying our products, we provide them training so that they can use and maintain

the machine independently.

We will offer to customers technical support in time. If needed, we will offer on-line guidance

and assistance.

We can provide free technical guidance if customers need new equipment, add or rebuild

equipment.

We will prioritize the product upgrading of previous customers.

Our Company