2021 PE PP PPR PVC UPVC HDPE Plastic Pipe Extrusion Extrude Extruder Machine Production ...

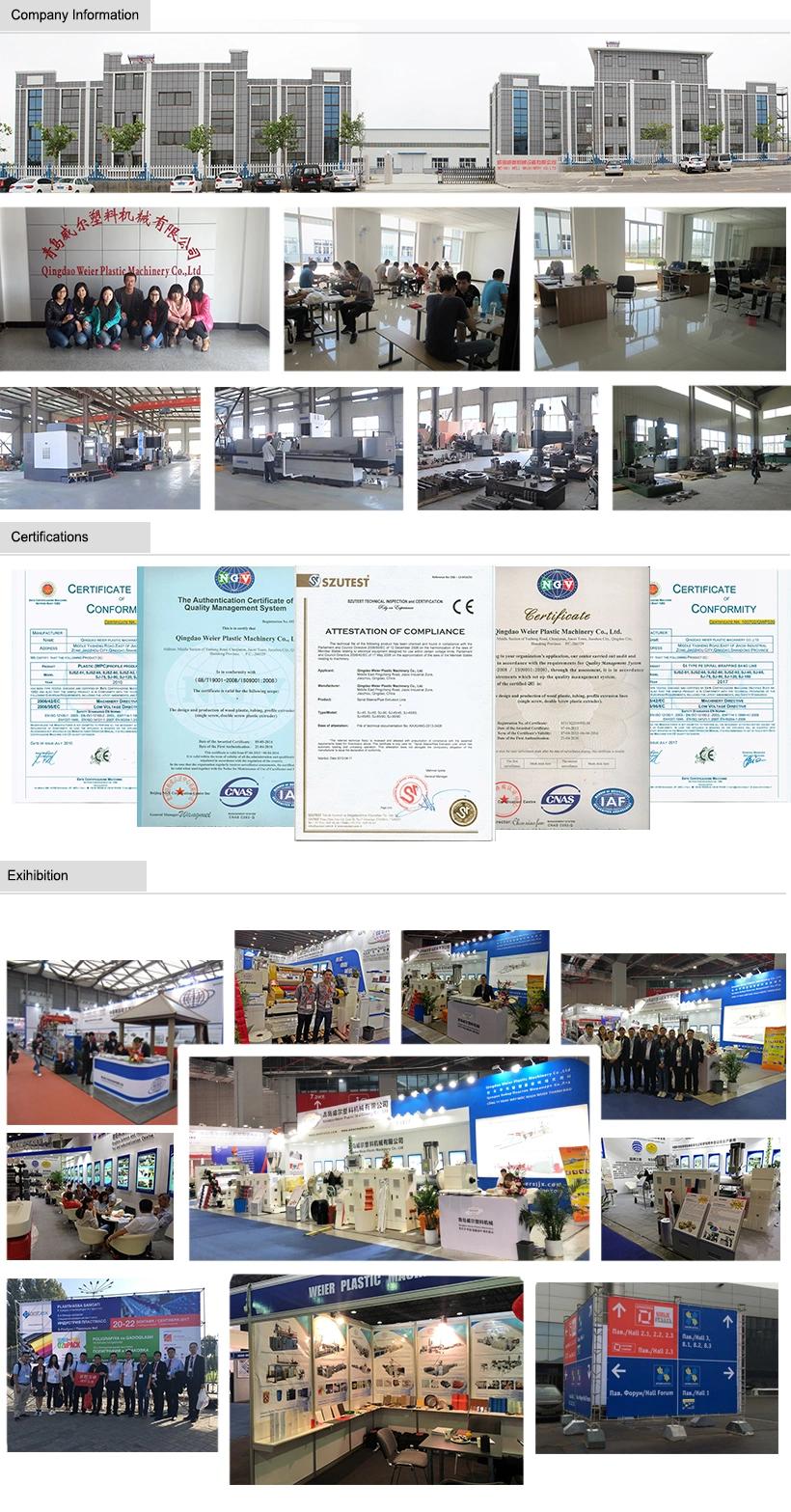

Qingdao Weier Plastic Machinery Co., Ltd.- After-sales Service:Provide Technical Services

- Warranty:1 Year

- Type:Pipe Extruder

- Plastic Processed:PVC

- Product Type:Extrusion Molding Machine

- Feeding Mode:One Feed

Base Info

- Model NO.:sjsz-65,132

- Assembly Structure:Integral Type Extruder

- Screw:Twin-Screw

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Power Supply:380V Three Phase

- Center Height:1000mm

- Extruder:Conical Twin Screw Extruder

- Project:Turn Key Project

- Technique:From Gemrnay

- Motor:AC Motor

- Transport Package:Export Package

- Specification:CE ISO9001 2008

- Trademark:WEIER

- Origin:China

- HS Code:84772090

- Production Capacity:50 Sets ,Year

Description

Basic Info.

Model NO. sjsz-65/132 Assembly Structure Integral Type Extruder Screw Twin-Screw Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Power Supply 380V Three Phase Center Height 1000mm Extruder Conical Twin Screw Extruder Project Turn Key Project Technique From Gemrnay Motor AC Motor Transport Package Export Package Specification CE ISO9001 2008 Trademark WEIER Origin China HS Code 84772090 Production Capacity 50 Sets /YearProduct Description

PVC PIPE EXTRUDER PRODUCTION LINEThe pipe diameter can be from 20mm--800mm (max)

Our products have been exported to many counties in Middle East, Africa, Southeast of Asia, etc.

1. Main technical performance: ( take exmaple for 50-200mm PVC pipes)

(1) material: PVC powder, etc as per formula

(2) Output: Will differ with different processing material and operation condition.

SJSZ-65/132 PVC 200-220kg/h

(3) production speed: 0.3-6m/min

(4) Central height of production line: 1000mm

(5) Operation direction: From left to right

(6) machine color: As our company's standard

2. Equipment List for PVC OPipe Poduction Line:

2.1 Automatic spiral feeding system

2.2 SJSZ-65/132 conical twin screw extruder

2.3 Die & Mould ( including also heater, sizing sleeves)

2.4 Vacuum sprinkling cooling water tank

2.5 Caterpillars haul off

2.6 Automatic cutter

2.7 Reversal stacker

2.8 Electrical control system

The following machine will be as per customer's choice:

SWP-360 crusher

SMP-400 PVC mill

SHRL-200/500 high speed cooling mixer

Full automatic belling machine with U or R type belling molds

WHY CHOOSE WEIER?

(1)We are engaged in macromolecule science, is the director member of WPC (plastic & wood production council of Chinese plastic community)

(2)We cooperated with many domestic universities to develop special plastic machines to meet domestic and foreign customer's requirement.

(3)We become the test and industrialization centre of plastic engineering technology research institute of Qingdao Science and Technology University.

(4) we bring in and absorb advanced processing engineering of foreign plastic machines to realize chain service of technics and machines.

(5) We have experiences in this field since 1980s

(6) We have our production bases for WPC and plastic product in China with large scales, which shows our machine's production power

(7) We have strong technical teams and cooperate with China scientific institution to develop, improve and test our machine, to ensure what customers get are the most reliable machines from China.

(8) We select the most reliable mechanical and electrical parts for our machine with all famous reliable brands, with European CE certificated.

(9) We put our heart into every business with aim of long term cooperation.

(10) We have perfect service system-- Our president is devoting himself to pre-sale, on-sale and after-sale service. WEIER JUST DO WIN-WIN BUSINESS! ! !

WE have many ready PVC and PE pipe prduction lines in factory, welcome to visit our factory! For more details of our PVC, PE pipe making machine, pls do not hesitate to contact with me!