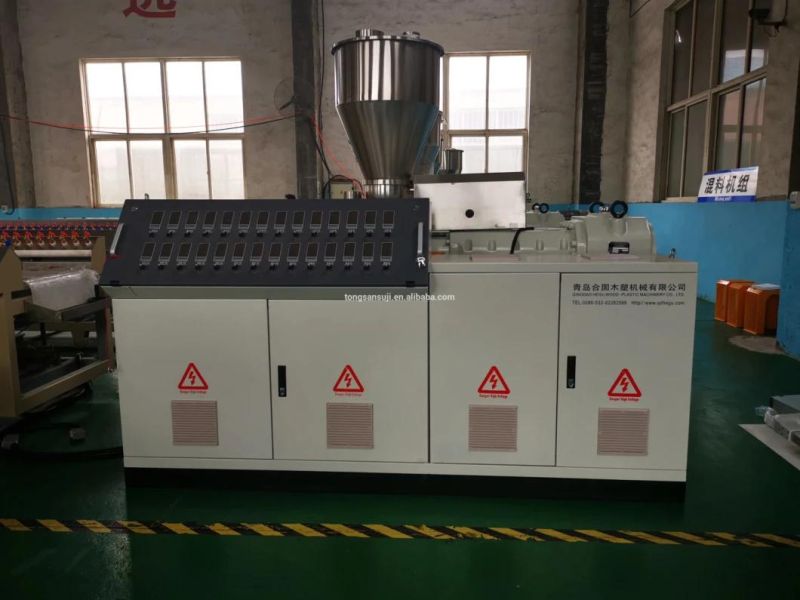

PVC Ceiling Panel Extruder Making Machine

Qingdao Tongsan Plastic Machinery Co., Ltd.- Type:Profile Extruder

- Plastic Processed:PVC

- Product Type:Profile Extrusion Molding Machine

- Feeding Mode:One Feed

- Assembly Structure:Integral Type Extruder

- Screw:Twin-Screw

Base Info

- Model NO.:SJSZ51,105

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Don′t Exhaust

- Automation:Automatic

- Computerized:Computerized

- Output (Kg/H):250-300

- Screw Diameter (mm):80

- Twin Screw Type:Co-Rotating Conical Twin-Screw

- Screw Speed (Rpm):1400 Rpm

- Voltage:3p,30V,50Hz or as Local

- Power (Kw):55

- Motor Brand:Siemens

- Main Electrical Component:ABB, Rkc, Omron, Shneider etc

- Door Board Width:800-1200mm

- Door Board Thickness:18-40mm

- Transport Package:Wooden Packing

- Specification:30m*2*2.5m

- Trademark:Tongsan

- Origin:Qingdao

- HS Code:84772090

- Production Capacity:300 Kg,H

Description

Extruder for PVC ceiling and wpc wall panel making machine

Conical double screw extruder specially designed for making PVC ceiling and wpc wall panel making machine

Model: SJMS51/105 model

Main power: 22KW

Capacity: 120-160 kg/h

Max. product width: 200mm

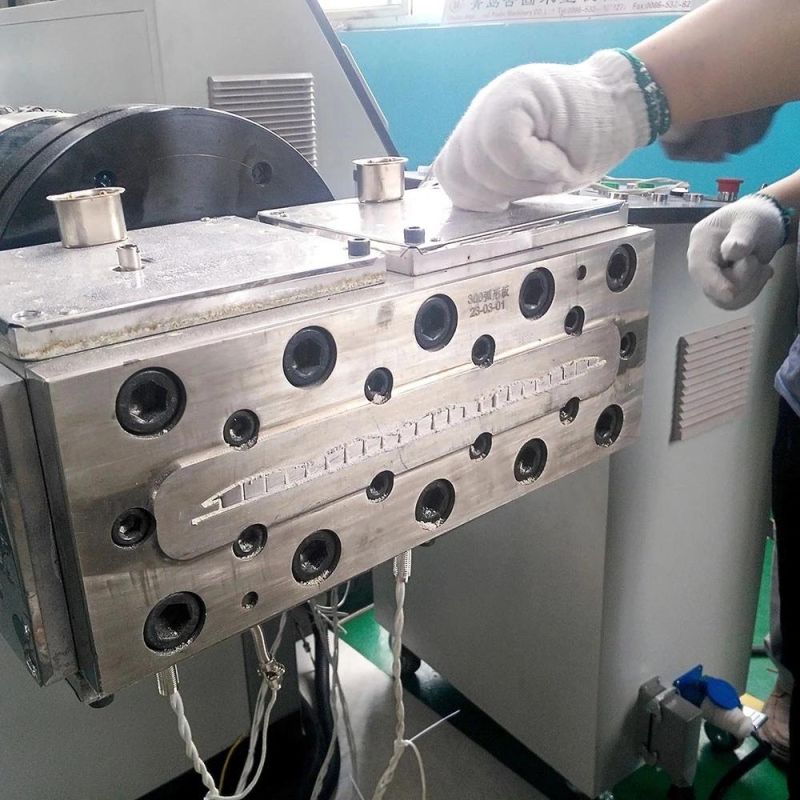

Die head and mold for PVC ceiling and wpc wall panel making machine

For making PVC ceiling and wpc wall panel making machine, it is necessary to increase the calibrator length to be 300mm*3 piece or 300*4 piece.

and the water cooling tank should be 2000mm*2 pcs or 3000mm*2 pcs

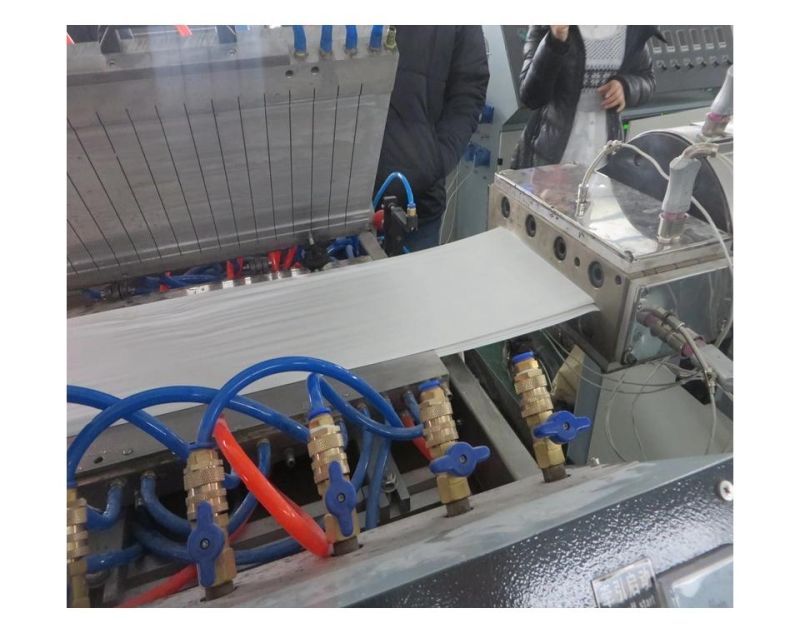

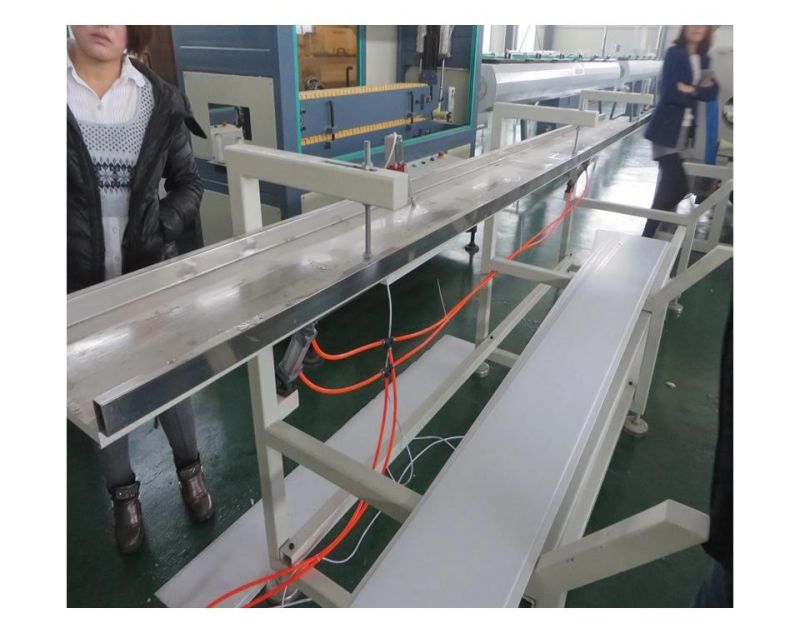

calibrating machine for PVC ceiling and wpc wall panel making machine

Length of table: 6meter customized

width of table: 1100mm, valiable inner width is 600mm

material of table: stainless steel

cooling method: water cooling and vacuum cooling.

vacuum pump: 7.5kw*1 sets,+5.5kw*2 sets

water pump: 2.2kw*1 set

haul off machine for PVC ceiling and wpc wall panel making machine

Haul off type: double caterpillar

length of haul off: 2.4 meter

control of haul off: frequency control

motor : 1.5 kw

gearbox: double gearbox

Cutting machine forPVC ceiling and wpc wall panel making machine

cutting method: automatic cutting

cutting control: PIC control

Length: fix length cutting

Electric control cabinet

ABB inverter

Siemens contractor

Omron temperature

Siemens PLC is optional