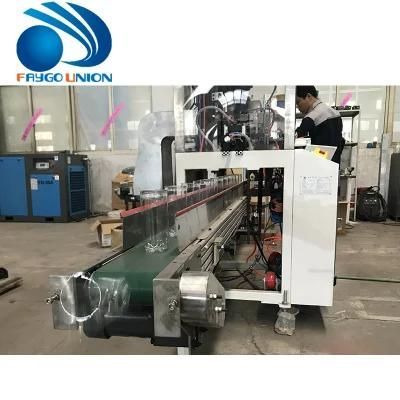

PU Ppt Poly PVC Cutting Machine for Plastic

Jiangsu Faygo Union Machinery Co., Ltd.- Transport Package:Film and Wood Box

- Trademark:Faygo Union

- Origin:Jiangsu

Base Info

- HS Code:8477800000

- Production Capacity:800-1200 Bottles,Hour

Description

Plastic bottle neck cutting machine advantages

1. Production line features:High output,economic labor and good quality.

2. The design is rational, structure is compact and operation is easy.

3. Manner of adjustable: frequency conversion controller.

4. Character: low noises. Save electricity30%

5. Extrude systemType: it adopts three section gradual change screw with rhombus shape, which contribute to the good plasticizing effect.

6. Lift Framework:adjusting the gap between mould inlet and the mould can minimize the remains of the products.

7. The automatic level is very high so save the salary and expenses.

8. Multifunction incision machine;Stable performance.You can adjust the speed and knife rest to make the bottle size cutting out meet the best sealing requirements.The product incision under high efficiency is smooth,neat and no laciness.

Packing by film or wooden cases.

Faygo Union Company is humbly accepting every customer's suggestions for the use of incision machine, we will improve our incision machine regularly according to the use of customers, so as to make it perfect.

Our company

FAYGO UNION GROUP has 3 branch factories. One is FAYGOBLOW which design and make blow molding machine for PET, PE etc. FAYGOBLOW has 5 patents of invention, and 8 patents utility models. FAYGO PET blow molding machine is one of fastest and most energy-efficient design in the world. Second factory is FAYGOPLAST, which make plastic extrusion machinery, including plastic pipe extruding line, plastic profile extruding line. Especially FAYGOPLAST can supply high speed up to 40 m/min PE,PPR pipe line. Third factory is FAYGO RECYCLING, which research new technology in plastic bottle ,film recycling processing and pelletizing. Now FAYGO RECYCLING can make up to 4000kg/hr. PET bottle washing line, and 2000kg/hr plastic film washing line.

Our factory is located in Zhangjiagang city, covers an area of 26,650 square meters. It only takes around two hours driving from SHANGHAI international airport. Welcome to visit our factory, and hope to cooperate with you in the near future.

PP/PET bottle neck cutting machine

Q1:Are you a trading company or a manufactory?

A:We are a manufactory,can give u best service .

Q2:What's your guarantee or the warranty of the quality if we buy your machines?

A:We offer you high quality machines with 1year guarantee . we will give u spare part free in 1 year

Q3:When can I get my machine after I paid?

A:We will deliver the machines on time as the date we agreed both side.

Q4:How can I install my machine when it arrives?

A:We will send our engineer to your side as soon as you get all your machines ready , for testing and teaching your technicians how to run the machines.

Q5:How about the spare parts?

A:After we deal down all the things , we will offer you a spare parts list for your reference.