Luxuary Vinyl Tile Flooring Machinery

Wuxi Boyu Plastic Machinery Co., Ltd.- Type:Sheet Extruder

- Plastic Processed:PVC

- Product Type:Extrusion Molding Machine

- Feeding Mode:One Feed

- Assembly Structure:Integral Type Extruder

- Screw:Twin-Screw

Base Info

- Model NO.:SJSZ110

- Engagement System:Conical Meshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Screw Design:Conical Twin-Screw

- Weight:~44.5 Tons

- Power:485-750kw Per Line

- Voltage:220-415V , 50-60Hz 3 Phase

- Function:Flooring Sheet Extrusion

- Certificate:Ce , ISO, TUV, UL, CSA

- Transport Package:Wooden Case Packing or Film

- Specification:Production Line layout: 50m (L) * 5m (W) * 8m (H)

- Trademark:Boyu

- Origin:Wuxi China

- Production Capacity:200 Lines Per Year

Description

Basic Info.

Model NO. SJSZ110 Engagement System Conical Meshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Screw Design Conical Twin-Screw Weight ~44.5 Tons Power 485-750kw Per Line Voltage 220-415V / 50-60Hz 3 Phase Function Flooring Sheet Extrusion Certificate Ce , ISO, TUV, UL, CSA Transport Package Wooden Case Packing or Film Specification Production Line layout: 50m (L) * 5m (W) * 8m (H) Trademark Boyu Origin Wuxi China Production Capacity 200 Lines Per YearProduct Description

Luxuary Vinyl Tile Embossed Flooring Extruding Production Machine Line(SZSJ110 Conical twin extruder + 5 roller calender with EIR function)

I. Design parameters

| No. | Items | Description |

| 01 | Operation conditions | 380V/3 phases/60Hz. (or customizable as per different country's standard voltage ) |

| 02 | Materials used | PVC powder, calcium carbonate, stabilizer, lubricant, small materials. Main Material and proportion: PVC: CaCo3 = 1:1 :2~3 |

| 03 | Extrusion rate | 800~1250kg/h; Line speed: 1.2~2.4m/min Daily capacity: 20-23 Mt/ 24hours ,Monthly capacity (30days, each day working 3 shifts 24 hours): 90,000m2/Line/Month |

| 04 | Product specifications | Maximum width is 1050mm (1350mm available for optional), thickness =2-9mm. Normal finished board width: 980mm Normal finished board thickness: δ=1.5~4.0mm |

| 05 | Total power of whole machine line | About 700KW (The exact total power may something floating as per different configuration requirements |

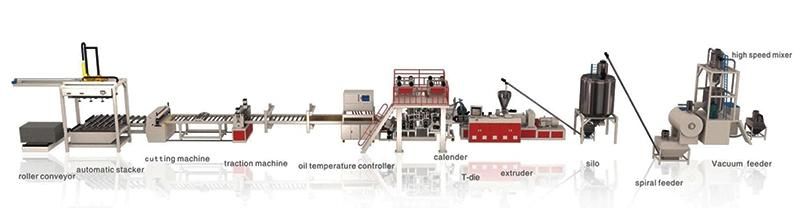

II.Equipment List & Quantity

| No. | Equipment Name | Quantity | Remark |

| 01 | Φ110/220 Conical twin-screw extruder | 1 Set | |

| 02 | Extrusion die | 1 Set | |

| 03 | Five-roller calender | 1 Set | |

| 04 | Film unwinding mechanism & magnetic powder controller | 2 Units | For two working position |

| 05 | Oil roller heating system (integral) | 1 Set | 4 units |

| 06 | Cooling bracket | 1 unit | |

| 07 | Longitudinal edge cutting mechanism | 1 unit | |

| 08 | Traction machine | 2 sets | |

| 09 | Length meter | 1 Set | |

| 10 | Plate shearing machine | 1 set | |

| 11 | Automatic plate lifting and stacking system | 1 unit | |

| 12 | Electric control cabinet | 1 unit | |

| 13 | Cooing water spray tank | 1 unit | |

| 14 | wear layer pre-heat device | 1 unit |

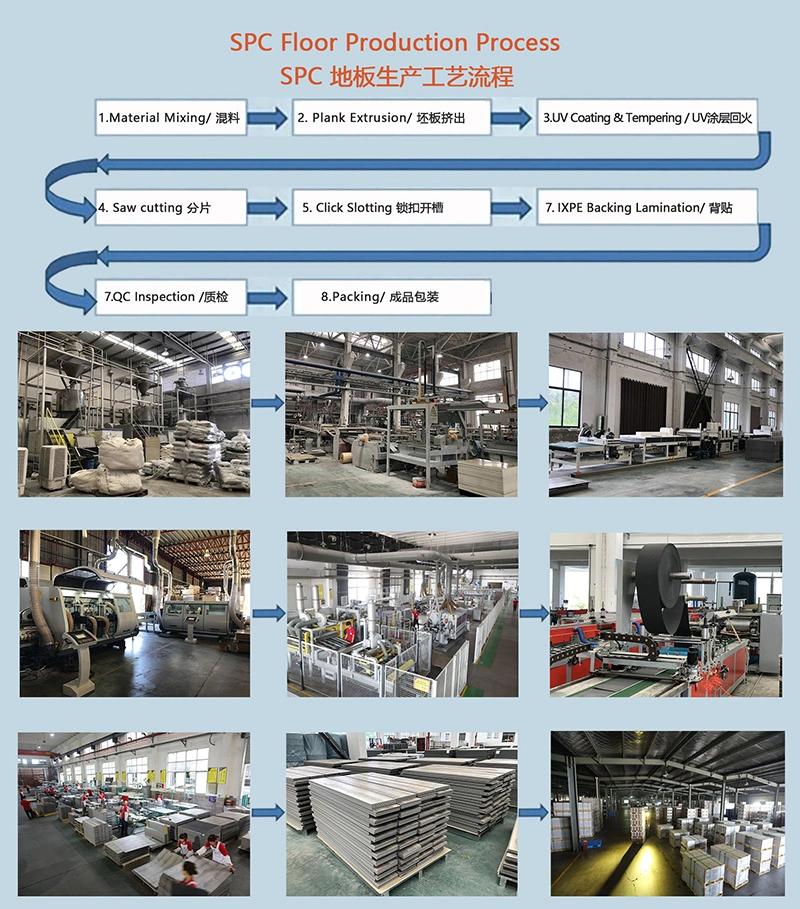

III.Production Flow

Material mixing → Extruder → Calender→ Cut-to-length →Stacking →UV coating →Saw cutting →

Slick slotting →Backing limitation →QC inspection → Packing

IV. Machine Line Layout

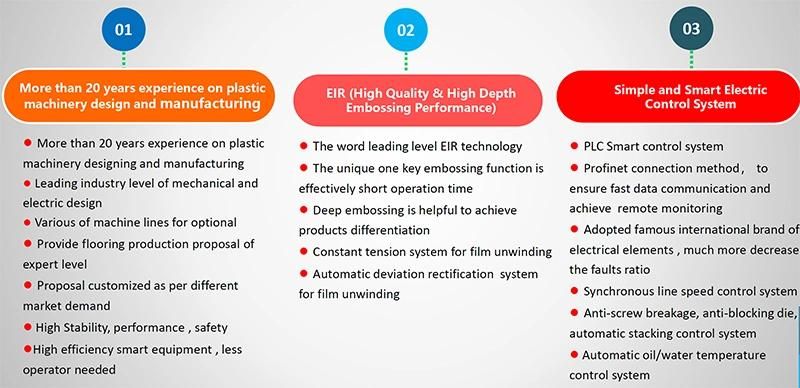

V. Advantages of BOYU WPC Production Machine Line

VI.Services

VII. Project Case

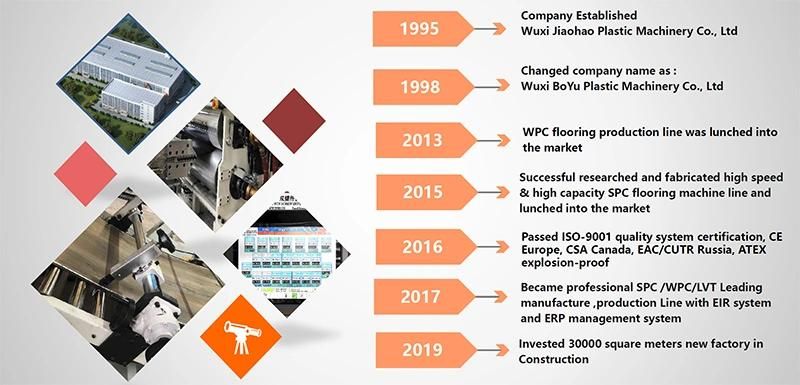

VII. Boyu Company Profile