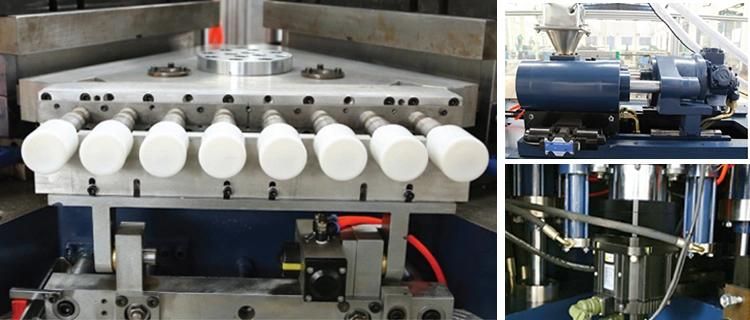

Eye Dropper Shampoo Bottle Injection Blow Molding Machine

Jiangsu Faygo Union Machinery Co., Ltd.- Type:Injection Blow Molding Machine

- Raw Material:PE

- Making Method of Parison:Injection Blowing

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008

Base Info

- Model NO.:FG40

- Name:Mineral Water Pet Bottle Blowing Machine

- Body Diameter:100mm

- Mold:Customized by Pet Bottle Blowing Machine

- Capacity:6800-7200 PCS,H

- Control:PLC Control, Mitsubishi

- Volume:250ml to 2L

- Cavity Number:4 Cavities

- Cylinder:Festo, Germany

- Work:Can Be Connected with Filling Machine

- Touch Screen:Siemens

- Transport Package:Wooden Packaging

- Specification:CE, ISO9001

- Trademark:Faygo Union

- Origin:Jiangsu Zhangjiagang

- HS Code:84773090

Description

Bottle Size

1.Volume:5ML-1000ML

2.Neck Dia:10-45MM

3.Height:35-200MM

4.Body Dia:45-90MM

Technical Parameters

Company Information

FAYGO UNION GROUP has 3 branch factories. One is FAYGOBLOW which design and make blow molding machine for PET, PE etc. FAYGOBLOW has 5 patents of invention, and 8 patents utility models. FAYGO PET blow molding machine is one of fastest and most energy-efficient design in the world. Second factory is FAYGOPLAST, which make plastic extrusion machinery, including plastic pipe extruding line, plastic profile extruding line. Especially FAYGOPLAST can supply high speed up to 40 m/min PE,PPR pipe line. Third factory is FAYGO RECYCLING, which research new technology in plastic bottle ,film recycling processing and pelletizing. Now FAYGO RECYCLING can make up to 4000kg/hr. PET bottle washing line, and 2000kg/hr plastic film washing line.

Our factory is located in Zhangjiagang city, covers an area of 26,650 square meters. It only takes around two hours driving from SHANGHAI international airport. Welcome to visit our factory, and hope to cooperate with you in the near future.

Our Services

1> The machine will be tested and checked at our workshop before delivery.

2>After one year, we will supply accessories are provided only one the cost price.

3>Free production technology and process configuration.

4>Installation: Experts' team to buyer's country after confirmation that the goods arrived in site and civil works completed get ready for installation. Funds for trip need to be payed by client and extra salary $60/day during the engineer's journey.

5>Warranty: One year from the date of Installation or acceptance of the Plant whichever comes first

6>We will reply you within 24 hours