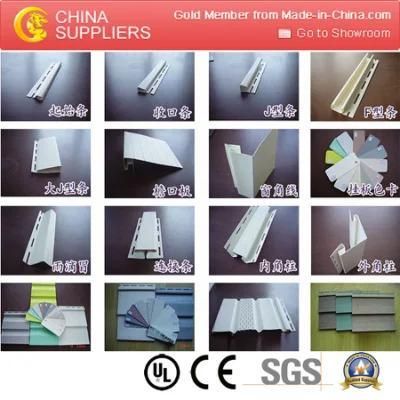

High Quality PVC Ceiling Making Machine

GPM Machinery (Shanghai) Co., Ltd.- Product Type:PVC Board

- Board Layers:Single Plate

- Screw No.:Double-screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008, UL, QS, GMP

Base Info

- Model NO.:GYF

- Customized:Customized

- Condition:New

- Product Name:PVC Ceiling Making Machines

- Processing Type:Board Extrusion

- Usage:Wall Panel,Ceiling

- Motor:Simens

- Inverter:ABB Brand

- Contactor:France Schneider Contactors

- Temperature Control:Japan Omron

- Output:500-600kg,H

- Motor Power:37-132kw

- Transport Package:PE Film Winding Wrapping

- Specification:0.4-5mm

- Trademark:GPM

- Origin:Shanghai

- HS Code:8477209000

- Production Capacity:500 Sets,Year

Description

PVC CEILING MAKING MACHINES TECHNICAL SPECIFICATIONModel GSZ65/132-GF800 GSZ80/156-GF1200 GSZ92/188-GF1600 Thickness 0.2-8mm 0.2-25mm 0.3-36mm Width 800mm 1220mm 1600kw Main power 37KW 75KW 110KW Product type Blister sheets,decorative panels, edge banding, advertizing board,architectural plates Capacity 200kg/h 400kg/h 800kg/h

List of the line

For choosing the proper machine and saving your time, please read these bellow guides carefully

1). What kinds of plastic machinery do you need ? Or what material do you want to process?

2). What capacity do you want? (kg/h )

3). What is the max and min size of the finish products .For example, the width and thickness of sheet(mm)?

4) What is the electric device you need ? Siemens, Omron or domestic ?

5) When do you want the machine? (Times for delivery)

6) Other requirements about the machine you want.

if you are interested in this machine ,please contact me:

mob : +86 13915723896 ( or +86 13817556740 )

Jeremy He

List of the line

| NO. | Name | Qty | Power (KW) | Length (m) | Weight (T) |

| 1 | GSZ65/132 conical twin screw extruder | 1set | 68 | 4 | |

| 2 | XDX800 vacuum calibration table | 1set | 30 | ||

| 3 | XQY800 haul-off unit (Separated type) | 1set | 4.4 | ||

| 4 | XQG800 cutter (Separated type) | 1set | 2.5 | ||

| 5 | XFL800 stacker | 1set |

| Type | GSZ65 / 132 |

| ――Electric control cabinet | Main transducer and feeder's transducer: ABB; Air switch: SIEMENS |

| ――Type of Temperature control curve | Temperature fluctuating self-adjusting (PID Type) |

| ――Origin places of the speedometers | Imported brand |

| ――Pressure Display | With melt pressure display |

| ――Connection of die head with flange | By bolts |

| ――The display method of data in operating panel | Temperature meter controller RKC (JAPAN ) |

For choosing the proper machine and saving your time, please read these bellow guides carefully

1). What kinds of plastic machinery do you need ? Or what material do you want to process?

2). What capacity do you want? (kg/h )

3). What is the max and min size of the finish products .For example, the width and thickness of sheet(mm)?

4) What is the electric device you need ? Siemens, Omron or domestic ?

5) When do you want the machine? (Times for delivery)

6) Other requirements about the machine you want.

if you are interested in this machine ,please contact me:

mob : +86 13915723896 ( or +86 13817556740 )

Jeremy He