Multi-Function Double Shaft Shredder for Solid Waste/Medical Garbage/Domestic Waste

Qingzhou Aoerheng International Trade Co., Ltd.- After-sales Service:Lifelong Service

- Warranty:Two Years

- Type:Cutting Shredder

- Raw Material:Kitchen Waste Domestic Garbage

- Structure:Top Feed

- Knife Classification:Piece Knife Crusher

Base Info

- Model NO.:HEHA-2S0410

- Knife Roll:Solid Knife Roller

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008, QS, UL, GMP

- Frame:Integral Steel Frame

- Blade Material:9crsi

- System:PC Automatic Control System

- Feeding Mode:Top Feed

- Power(Kw):37*2

- Size (mm):1000*830*440

- Transport Package:Wooded Box and Bulk

- Specification:5t,day

- Trademark:Aoerheng

- Origin:China

- HS Code:84778000

- Production Capacity:50000 Sets , Year

Description

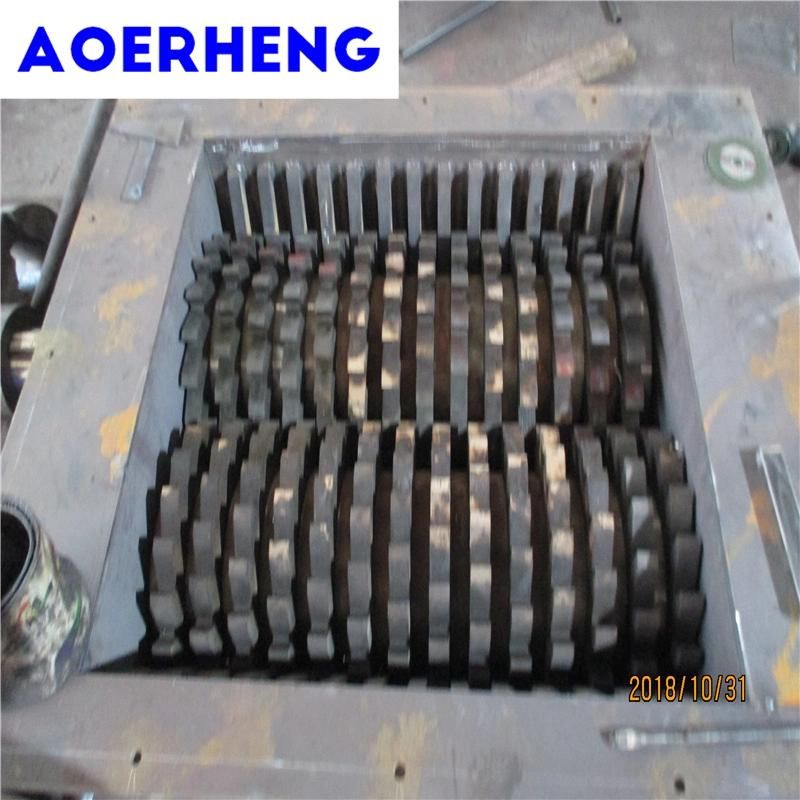

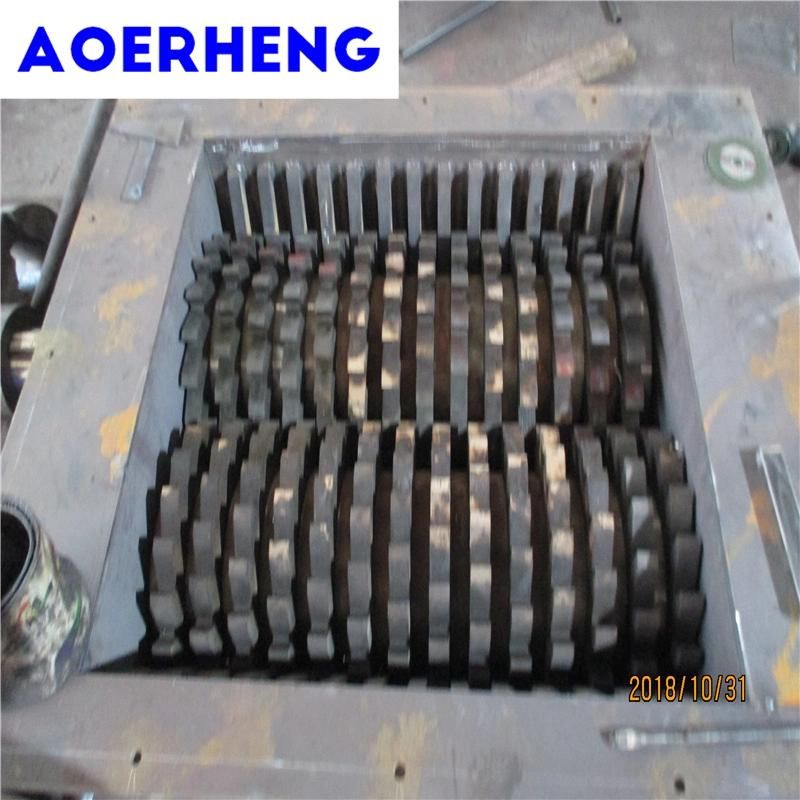

Pineapple knife structure

It is suitable for tearing hard plastics such as circuit boards, and can

tear materials to a size of less than 10mm

SW type cutter body structure

SW type cutter body structure

It is suitable for tearing general products, such as wood. Fragile or

brittle materials such as aluminum engine housing SPR knife structure

It is suitable for treating domestic wastes such as RDF and MSW for

pre crushing and unpacking, and the material discharge is less than

300mm

Assembly tool body structure

Assembly tool body structure

Suitable for tearing heavy metals or plastics, such as refrigerators,

metal barrels and materials above 10mm Integral cutter body structure

It is suitable for tearing up all kinds of materials, such as electronic

waste, hard plastic, rubber and packaging barrels of all kinds of

materials

3. Performance characteristics of double shaft shredder:

The materials vertically fall into the high-speed rotating impeller from the upper part of the machine. Under the action of high-speed centrifugal

force, they are separated with another part in the form of umbrella. The materials around the impeller produce high-speed impact and crushing.

After the materials collide with each other, they will form eddy currents between the impeller and the casing, collide and rub with each other for

many times, and discharge directly from the lower part, Form a closed circuit for multiple cycles, and the screening equipment controls to

achieve the required particle size of finished products.

4. Equipment operation:

5.1 preparation:

before starting the machine, first check whether there are materials, sundries and jamming in the crushing chamber; before

starting the machine every day, check whether all fasteners are completely fastened, and deal with them immediately if they are loose; check

the lubrication of each rotating part before starting the machine 5.2 start up:

the machine and transmission parts can be started up only after the inspection proves that they are in normal condition; the

machine must only be started under no load, otherwise it is easy to damage the motor, reducer, coupling, etc; start (jog the test run first) if

there is any abnormal condition or abnormal sound, stop the start immediately, find out the cause and eliminate the fault before starting again 5.3machine operation:

When the machine is running, the maintenance personnel should often go to the side of the machine to observe the operation: whether the

machine has abnormal sound. If it occurs, first determine the position, and then stop the machine for inspection and treatment; whether the

temperature rise of the motor is too high. Under normal conditions, the maximum temperature shall not exceed 80 ºC; check whether the bolts

at the rotating part are loose. If they are loose, stop the machine immediately. 5.4shut dowu:

Before the machine stops working normally, the feeding shall be stopped first, and the crusher can be stopped only after all materials in the

standby are broken. In case of machine failure or dangerous situation, the power supply can be cut off immediately.

5.Specifications and technical parameters of double shaft shredder:

erial number model Tear cavity size

long×wide×high

(mm) Blade diameter

(mm) blade thickness

(mm) spindle speed

(rpm) motor power

(kw) Tearing particle size

(mm) yield

(t/h) 1 2S0206 600×410×230 Φ200 15-30 12-25 11*2 3-30 0.3-0.6 2 2S0208 800×410×220 Φ200 15-30 12-25 15*2 3-30 0.5-1.0 3 2S0308 800×620×330 Φ300 15-35 10-22 18.5*2 3-30 0.8-1.6 4 2S0310 1000×620×330 Φ300 20-40 10-22 22*2 3-30 1.2-2.0 5 2S0312 1200×620×330 Φ300 20-40 9-16 30*2 3-30 1.8-2.8 6 2S0410 1000×830×440 Φ400 20-40 9-16 37*2 3-30 2.0-3.6 7

2S0412 1200×830×440 Φ400 20-45 9-15 45*2 3-30

6.Transport:

It is suitable for tearing hard plastics such as circuit boards, and can

tear materials to a size of less than 10mm

SW type cutter body structure

SW type cutter body structureIt is suitable for tearing general products, such as wood. Fragile or

brittle materials such as aluminum engine housing SPR knife structure

It is suitable for treating domestic wastes such as RDF and MSW for

pre crushing and unpacking, and the material discharge is less than

300mm

Assembly tool body structure

Assembly tool body structureSuitable for tearing heavy metals or plastics, such as refrigerators,

metal barrels and materials above 10mm Integral cutter body structure

It is suitable for tearing up all kinds of materials, such as electronic

waste, hard plastic, rubber and packaging barrels of all kinds of

materials

3. Performance characteristics of double shaft shredder:

The materials vertically fall into the high-speed rotating impeller from the upper part of the machine. Under the action of high-speed centrifugal

force, they are separated with another part in the form of umbrella. The materials around the impeller produce high-speed impact and crushing.

After the materials collide with each other, they will form eddy currents between the impeller and the casing, collide and rub with each other for

many times, and discharge directly from the lower part, Form a closed circuit for multiple cycles, and the screening equipment controls to

achieve the required particle size of finished products.

4. Equipment operation:

before starting the machine, first check whether there are materials, sundries and jamming in the crushing chamber; before

starting the machine every day, check whether all fasteners are completely fastened, and deal with them immediately if they are loose; check

the lubrication of each rotating part before starting the machine

the machine and transmission parts can be started up only after the inspection proves that they are in normal condition; the

machine must only be started under no load, otherwise it is easy to damage the motor, reducer, coupling, etc; start (jog the test run first) if

there is any abnormal condition or abnormal sound, stop the start immediately, find out the cause and eliminate the fault before starting again

When the machine is running, the maintenance personnel should often go to the side of the machine to observe the operation: whether the

machine has abnormal sound. If it occurs, first determine the position, and then stop the machine for inspection and treatment; whether the

temperature rise of the motor is too high. Under normal conditions, the maximum temperature shall not exceed 80 ºC; check whether the bolts

at the rotating part are loose. If they are loose, stop the machine immediately.

Before the machine stops working normally, the feeding shall be stopped first, and the crusher can be stopped only after all materials in the

standby are broken. In case of machine failure or dangerous situation, the power supply can be cut off immediately.

5.Specifications and technical parameters of double shaft shredder:

long×wide×high

(mm)

(mm)

(mm)

(rpm)

(kw)

(mm)

(t/h)

6.Transport: