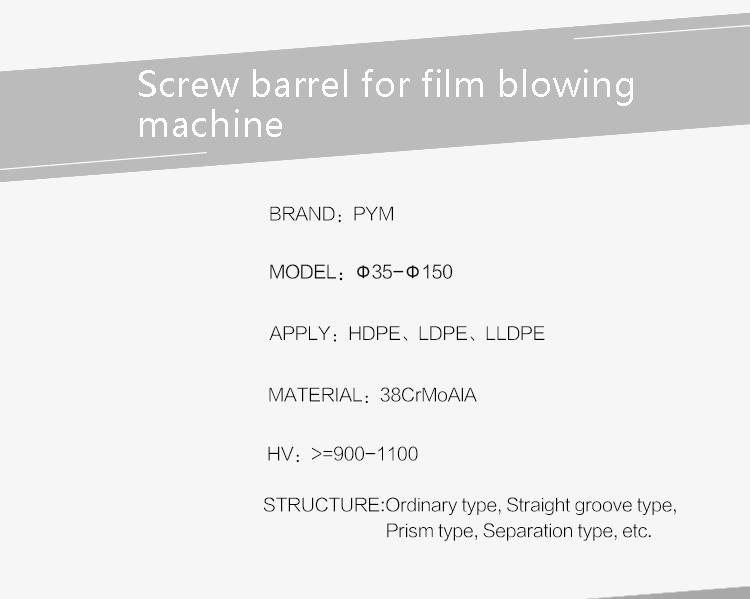

Duplex Metal Spraying Screw Barrel

Zhejiang Pinbo Plastic Machinery Co., Ltd.- Standard:GB

- Technics:Press

- Material:Metal

- Type:Piston Extruder

- Screw:Twin-Screw

- Automation:Automatic

Base Info

- Model NO.:Spraying screw barrel

- Computerized:Computerized

- Plastic Processed:PE

- Base Material:38crmoaia, 42CrMo

- Diameter for Single Screw:20-500mm

- Screw Design:Single Screw

- Application:PP PVC PE

- Certificat:Ce BV SGS TUV

- Transport Package:Stardand

- Specification:CE SGS BV TUV

- Trademark:PYM

- Origin:Wenzhou, Zhejiang

- HS Code:847790000

- Production Capacity:300set,Sets Per Month

Description

Basic Info.

Model NO. Spraying screw barrel Computerized Computerized Plastic Processed PE Base Material 38crmoaia, 42CrMo Diameter for Single Screw 20-500mm Screw Design Single Screw Application PP PVC PE Certificat Ce BV SGS TUV Transport Package Stardand Specification CE SGS BV TUV Trademark PYM Origin Wenzhou, Zhejiang HS Code 847790000 Production Capacity 300set/Sets Per MonthProduct Description

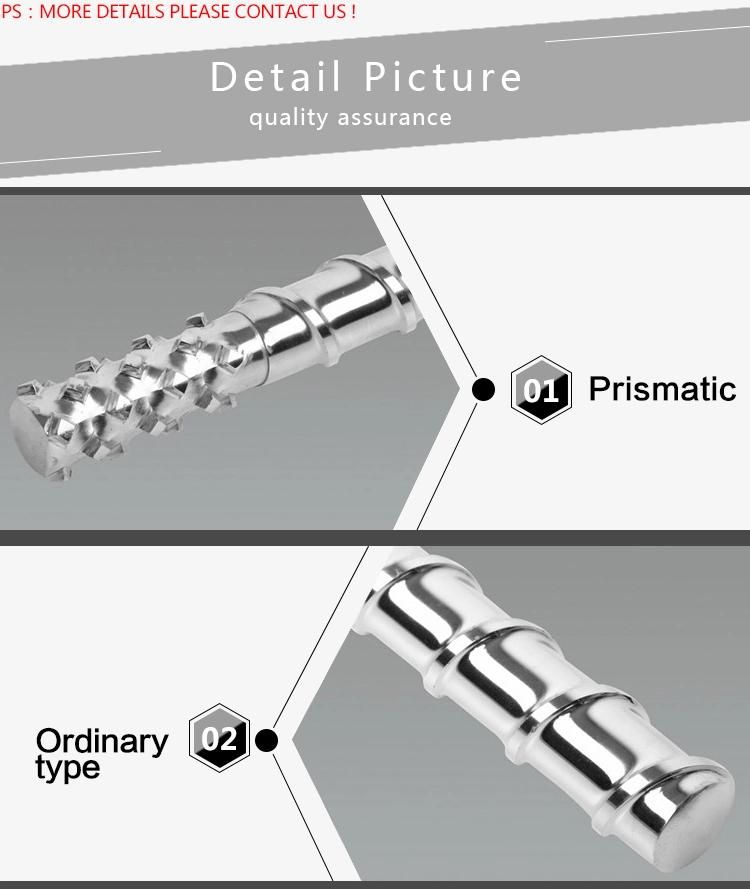

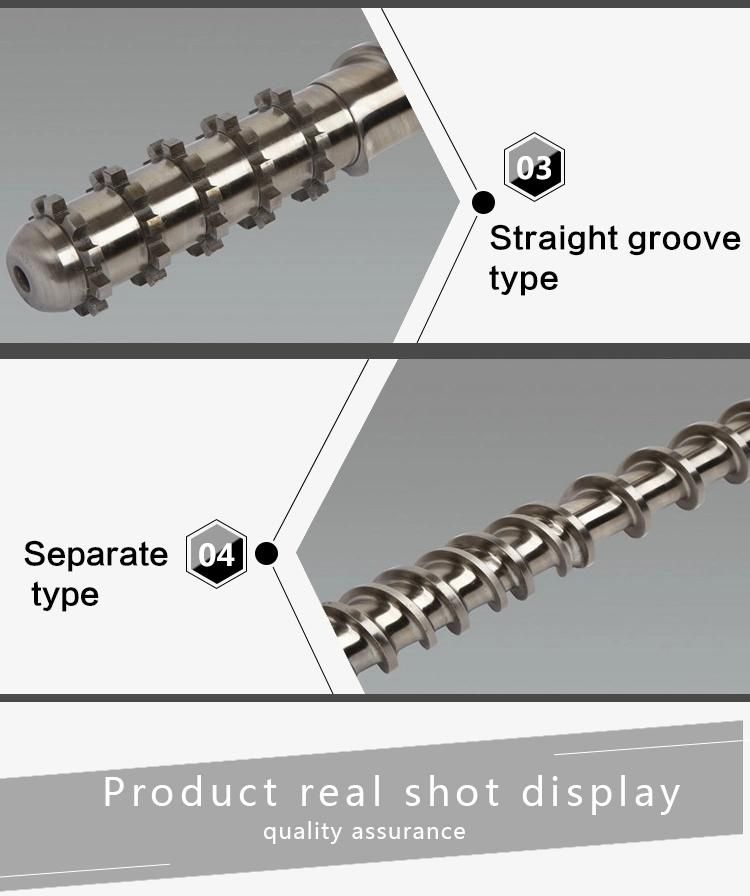

The main advantage of screw barrel:

A. Advanced Nitriding Technology

B. Anti-corrosion and Wear-resisting Duplex Metal Spraying Technoloy

C. We uses special alloy powders being sprayed and welded on the screw's ridge, and uses different alloy and welding methods for the screw of different functions.

D. Excellent raw materials

Certificate: BV, SGS, CE, TUV

Why choose us?

A> long time experience and history

B> long time nitriding treatment and heating treatment by itself

C>advanced Fanuk series CNC computer-controlled milling machines

D>depth hole drilling machine in 10meters length, which ensure the straigtnss of barrel inside.

E> CAD drawing confirmation before start making

F> Prompt after sale service

G>Land owner and registration capital 25, 000, 000RMB

Remarks: We can design and manufacture various kinds of screw barrels according to the customer's requirement

What is the packaging?

1) Wooden case package

2) Plastic film package

3) Suitable to transportation

4) As buyer request

5) One piece into one package

Payment: T/T, Western union, moneyGram and so on.

FAQ:

Q: What are we?

A: We are factory, with license of import and export goods by ourself.

Q; How to get to us?

A: The nearest airport is Wenzhou airport, and the nearest train station is Ruian station.

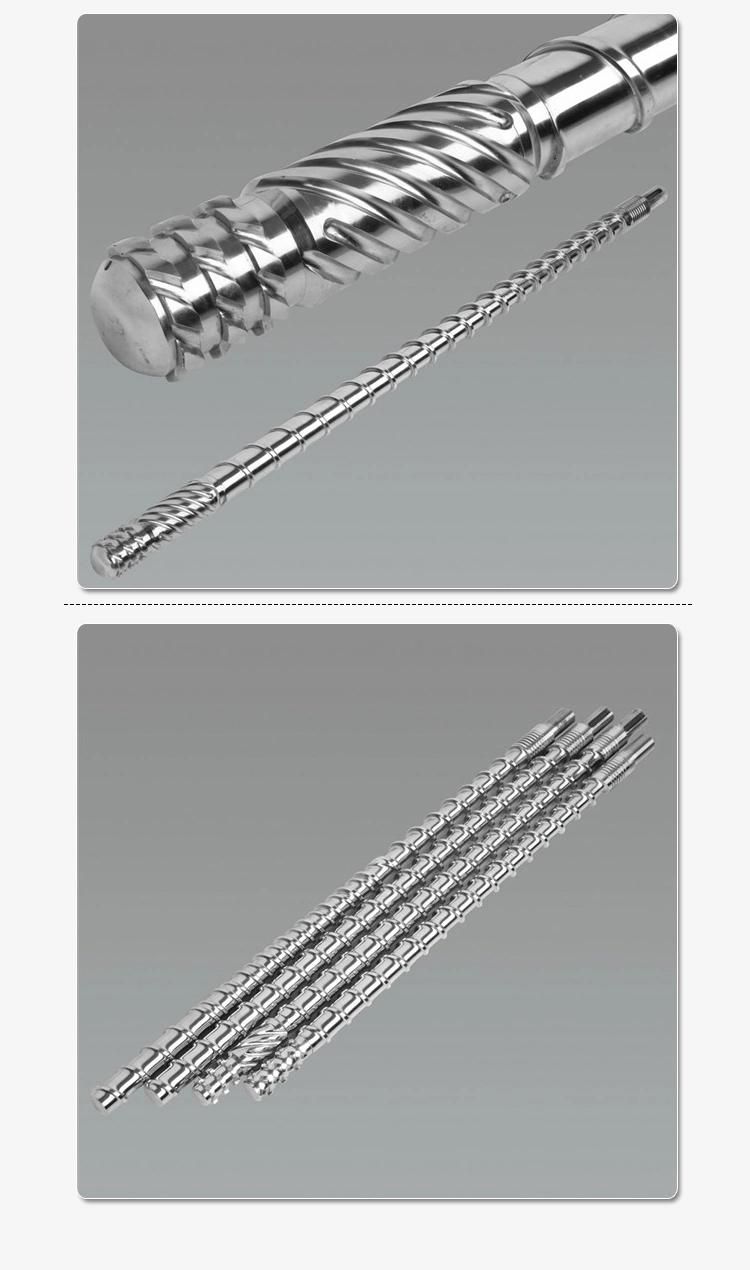

Q: How do we control the quality of screw barrel?

A: We have professional engineer and staffs to check every detail and dimensions from the raw materail, nitrding treatment and super grinding. We do the crucial nitriding treatment by ourself, we have nitriding ovens in depth8000mm, and do nitriding treatment in 8 days and nights, which greatly ensure the hardness of screw barrel.

After-Sales Service

1. If the after-sale problems we will reply you in time of after-sales request. Working time (Beijing time at 10: 00-20: 00).

2. We have a large number of professional and technical personnel, engaged in equipment design and development work, has a wealth of practical experience. Can provide you with the best after-sales service

Office:

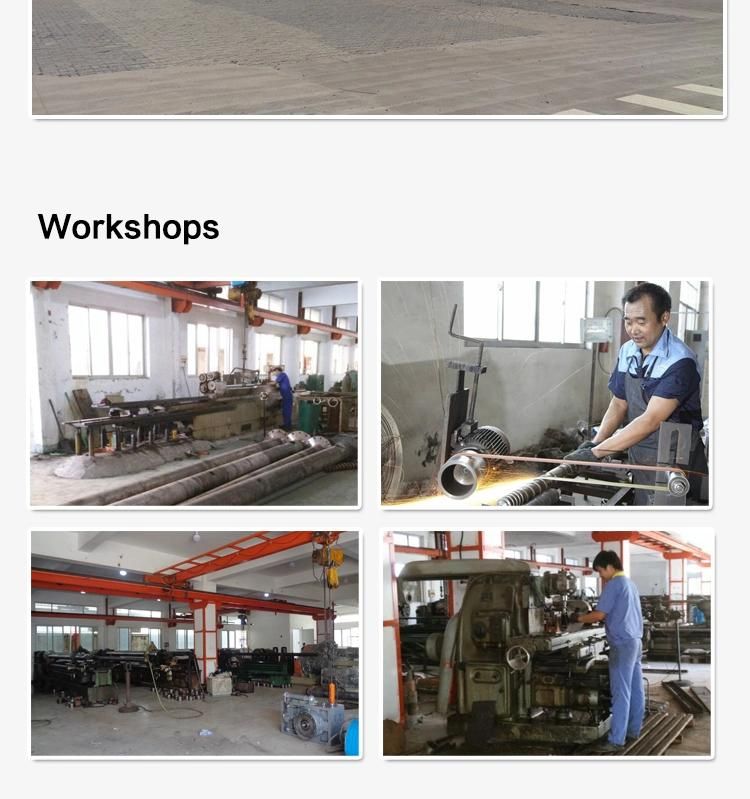

Zhejiang pinbo plastic machinery co.,ltd is located in ruian wenzhou city with brand of PYM(Former Ruian yumin machine screw co.ltd since 1988). The company is specialized in making screw barrel, gearbox zlyj series, t die, filter and extruder machine. It has become one of the largest supplier of main parts in Ruian city which is the basement of plastic machines.

Welcome to visit our company! Any question pls feel free to contact us. OUR COMPANY IS YOUR BEST CHOICE...

| Product | The best single screw barrel for extruder in ruian |

| Material | 38 CrMoAlA(JIS SACM645); 42 CrMo(JIS SCM440) |

| Hardness of nitrogen treatment | HV900°~1100° |

| Tempering hardeness | HB240 ° ~280° |

| Depth of nitrogen layer: | 0.6~0.8mm |

| Nitrided Brittleness | above 1 stage |

| Surface Roughness | Ra0.4 um |

| Screw straightness | 0.015mm |

| Hardess of surface chromium-plating after Nitriding | HV≥950HV |

| Chromium plating Depth | 0.025-0.085mm |

| Alloy Depth | 2.5mm-4mm |

| Alloy hardness | HRC62°~72° |

| Heating-treatment | nitrogen ,electroplated hard -chrome finish,high frequency quenching |