High Capacity Plastic Recycling Plant Pet Bottle Washing Machine

ZHANGJIAGANG RETECH MACHINERY CO., LTD.- Warranty:1 Year

- Material Processed:Plastic Bottle

- Plastic Type:PET

- Screw:Single-Screw

- Automation:Automation

- Certification:ISO9001:2008, CE

Base Info

- Model NO.:RM300,500,1000,1500,2000,2500,3000

- Voltage:380V, 50Hz, 3p (Can Be Customized)

- Moisture:<1%

- Flakes Size:12-14 mm

- PVC Content:Less Than 150 Ppm

- Capacity:300-3500kg,Hr

- Automatic Grade:Semi-Automatic

- Raw Material:Pet Bottle Waste

- Marketing Type:New Product 2021

- Final Product:Clean Pet Bottle Flakes

- Key Words:Pet Bottle Washing Machine

- Place of Origion:Jiangsu, China

- Transport Package:Stretch Film Packing

- Specification:35000mm*5000mm*4200mm

- Trademark:Retech machinery

- Origin:China

- HS Code:8477800000

- Production Capacity:100pieces,Year

Description

Overview

2. After the commissioning, we will package the equipment by standard export package for shipment.

3. According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

4. Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the customers' project.

Product Overview

Product Description

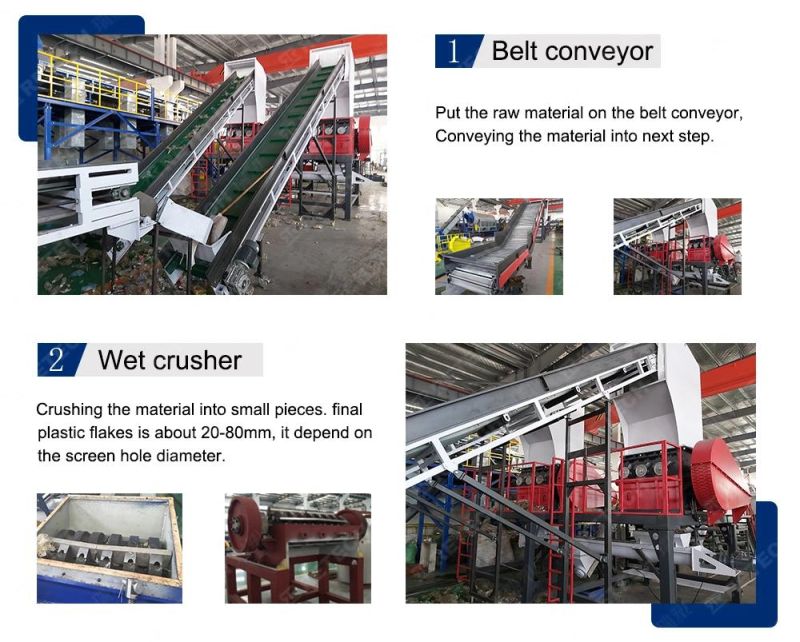

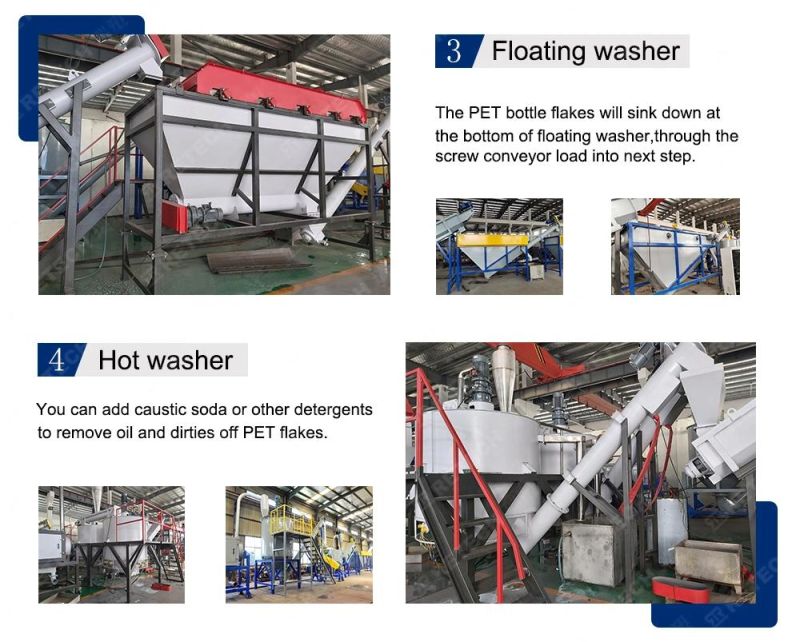

Detailed Photos

Our Advantages

Product picture

Our machine

Loading container

Our Service

THE AFTER-SALE SERVICE OF RETECH MACHINE!

THE AFTER-SALE SERVICE OF RETECH MACHINE!

2. After the commissioning, we will package the equipment by standard export package for shipment.

3. According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

4. Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the customers' project.