PS Sheet Vacuum Forming Machine

Zhejiang Hongyin Machinery Co., Ltd.- After-sales Service:Video Technical Support, Free Spare Parts

- Warranty:1 Year

- Certification:CE, ISO9001:2008, QS

- Column number:Four Column

- Molding Method:Pressing

- Automatic Grade:Automatic

Base Info

- Model NO.:HY-720,1220

- Computerized:Computerized

- Automation:Automatic

- Driven Type:Electric

- Shaping Mode:Die Molding

- Application:Boxes, Trays, Fast Food Boxes, Dishes, Lids, Cooki

- Raw Material:Pet, PVC, PS, PP

- Max Forming Area:720*1220mm

- Forming Height:0-165mm

- Production Speed:200-600 Times,Hour

- Eject-Die:Shake to Mould-Down

- Electric Furnace Rating Power:60 Kw

- Vacuum Pump Power:3.0 Kw

- Power:380V 50Hz Three Phases

- Weight:3000 Kg

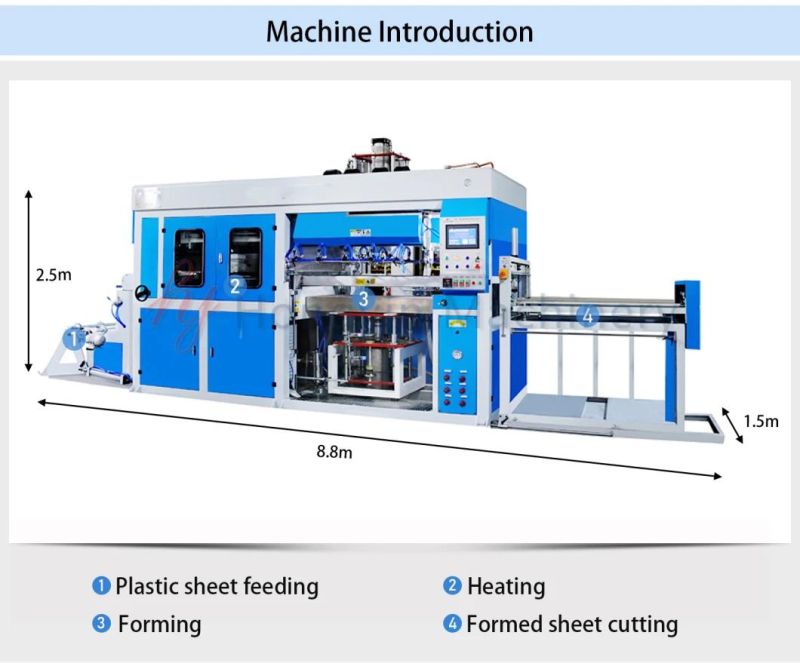

- Overall Dimension:(L)8800*(W)1500*(H)2500mm

- Transport Package:Wooden Case

- Specification:(L)8800*(W)1500*(H)2500mm

- Trademark:HongYin

- Origin:Ruian, Zhejiang

- HS Code:84774090

- Production Capacity:60 Sets,Year

Description

Basic Info.

Model NO. HY-720/1220 Computerized Computerized Automation Automatic Driven Type Electric Shaping Mode Die Molding Application Boxes, Trays, Fast Food Boxes, Dishes, Lids, Cooki Raw Material Pet, PVC, PS, PP Max Forming Area 720*1220mm Forming Height 0-165mm Production Speed 200-600 Times/Hour Eject-Die Shake to Mould-Down Electric Furnace Rating Power 60 Kw Vacuum Pump Power 3.0 Kw Power 380V 50Hz Three Phases Weight 3000 Kg Overall Dimension (L)8800*(W)1500*(H)2500mm Transport Package Wooden Case Specification (L)8800*(W)1500*(H)2500mm Trademark HongYin Origin Ruian, Zhejiang HS Code 84774090 Production Capacity 60 Sets/YearProduct Description

PS Sheet Vacuum Forming Machine

The vacuum machine overview:

HY-720/1220 Plastic vacuum forming machine is designed by the principle of mechanical-electrical-pneumatic integration. It adopts PLC control system, panel and digital power control. This full-automatic forming equipment for thermoforming plastic sheet includes feeding, heating, forming, cooling, mold ejecting, cutting by one process.

Application:

HY-720/1220 vacuum machine is mainly applied to plastic sheet material molding, such as PS, HIPS, PVC, PET, PP and flocking sheet, etc. which produce all kinds of trays, trays for medicine injection, oral liquid, vegetables, telephones, cookies, tool, hardware, electron and disposable tableware, etc.

Prameters:

| 1.Max Forming area | 720*1220mm |

| 2.Sheet width | 610-760mm |

| 3.Forming height | 0-165mm |

| 4.Thickness of sheet | 0.15-1.0mm |

| 5.Production speed | 200-600times/hour(depend on the shape of product and thickness of sheet) |

| 6.Mould-up move | Electromotion |

| 7.Electric oven power | 30 KW |

| 8.Heating device | 60 independent electronics non pole adjust(one control one) |

| 9.Traction motor power | 2.2KW |

| 10.Vacuum pump power | 3.0 KW |

| 11.Cooling-water machine power | 3.37 KW |

| 12.Power | 380V 50/60HZ three phases |

| 13.Air compressor | 15KW/20HP (remarked by customer) |

| 14.Dimension | (L)6600*(W)1450*(H)2800mm |

| 15.Weight | 3000kg |

About Zhejiang Hongyin Machinery Co., Ltd Services:

1. Purchase Service

Ruian Hongyin Company has a specialized and efficient working team. If you are new to the printing and packing area, Some samples of your products could be shown to us will be appreciated, we will give you a specialized suggestion of whole work.

2. Installation Service:

Hongyin company will assign 1 technician to coordinate installation, commissioning, and training, the cost for the return flight and suitable accommodation will be charged, and the allowance is USD 80-100 per day.

3. Warranty Service:

12 months limited warranty.

Starting from the date of machine arrival buyer's place excluding wear parts.

Shipping costs for easy broken parts to be replaced during the warranty period have to be borne by the customer.

If you are interested in our machine, please feel free and contact me.

Contact: Lynn