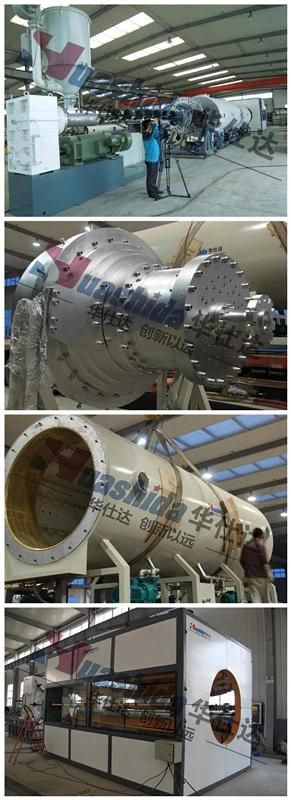

Plastic Pipe Extruder PE/PP/HDPE Vacuum Calibration Pipe Extrusion Device

Qingdao Huashida Machinery Co., Ltd.- Product Type:PE Pipe

- Warranty:6-12monthes

- Screw No.:Single-screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008, QS

Base Info

- Customized:Customized

- Condition:New

- After-sales Service:6-12monthes

- Pipe Range:960-1680mm

- Voltage:380V 50Hz

- Product Color:Black or Yellow

- Packaged:Wooden Cases and Pallets

- Pipe Style:Thin Wall Pipe

- Transport Package:Standard Package

- Specification:CE, SGS

- Trademark:Huashida

- Origin:Qingdao, China

- HS Code:8477209000

- Production Capacity:50 Sets,Year

Description

Basic Info.

Customized Customized Condition New After-sales Service 6-12monthes Pipe Range 960-1680mm Voltage 380V 50Hz Product Color Black or Yellow Packaged Wooden Cases and Pallets Pipe Style Thin Wall Pipe Transport Package Standard Package Specification CE, SGS Trademark Huashida Origin Qingdao, China HS Code 8477209000 Production Capacity 50 Sets/YearProduct Description

Plastic Pipe Extruder PE/PP/HDPE Vacuum Calibration Pipe Extrusion DevicePipes insulated with polyurethane foam

Pre-insulated pipe extrusion line designed by absorbing the tube extrusion developed technology from German and improved by Qingdao Huashida Machinery Co., Ltd.

The line is an integration design composed by extruder, vacuum calibrating, cooling, pulling, cutting, stacker. Great performance in automatic operation, extrusion capacity, steady and service life etc. Especially compared with the line use internal pressure method, vacuum calibrating method is much better than it for stiffness, pressure resistance and surface smooth.

Vacuum calibrating method pre-insulated pipe outside casing extrusion line is the most advanced and popular machinery in the world.

In the practice of domestic construction becomes increasingly used energy-saving technology trenchless laying of pipelines, using pipes and fittings with industrial thermal insulation of rigid polyurethane foam (PUF insulation) in protective shell.

Pipelines PUF insulation intended for installation of heating networks with a working pressure of 1.6 MPa and a water temperature to 403 ° K (130 ° C) with a valid short-term increase in temperature to 423 ° K (150 ° C).

Piping PUF insulation and fittings is a rigid structure "pipe in pipe" consisting of steel or galvanized steel carrier pipe, a layer of polyurethane foam insulation and the outer jacket pipe protective of high-density polyethylene - for underground installation or sheet galvanized steel - for above-ground pad.

Rigidity due to the presence of strong ties between the steel pipe layer polyurethane insulation and jacket pipe and provides pre-shot blast or blast cleaning the surface of the steel pipe, optimum performance polyurethane insulation, corona surface of polyethylene pipe shell.

By comparing PUF insulation surpasses analogues basic properties: Thermal conductivity and long trouble-free operation.

Significantly increases the reliability of the pipeline in the PUF insulation system operational availability of remote condition monitoring PUF insulation, which allows to detect and repair leaking coolant, preventing accidents typical for thermal networks of other designs.

Highly cost-effective use of pipelines in the foam insulation define the following parameters:

Simplifying the construction, maintenance and repair;

Increased service life of 30-40 years (traditional types of pipelines - 5-10 years);

Reduction of heat losses to 8% (traditional types of pipelines - 30-40%);

Reducing capital costs by 15-20% (not required construction of concrete channels and chambers for valves);

Reduced operating costs by 9 times;

Reduction in repair costs 3 times